Robot guide rails, also known as robot track systems or linear motion systems, are structural elements used to guide and support the movement of robotic systems along a predetermined path. These guide rails provide a stable and controlled environment for the robots. Here are some key points to understand about robot guide rails:

Purpose: The primary purpose of robot guide rails is to establish a defined path for robotic systems to follow. They ensure smooth and precise linear motion, allowing robots to move accurately and repeatedly along the desired trajectory.

Structure and Components: Robot guide rails typically consist of a track or rail system mounted on a stable structure, such as a floor or overhead framework. The rail system includes guide tracks or channels that serve as the guiding mechanism for the robot. The robot is equipped with compatible carriage or slider units that run along the guide tracks.

Types of Guide Rails: There are different types of guide rails available, including:

a. Linear Guide Rails: These rails incorporate rolling elements, such as ball bearings or roller bearings, to reduce friction and enable smooth linear motion.

b. Profile Guide Rails: Profile rails feature a linear guide system with recirculating ball bearings or roller bearings. They provide high load capacity and rigidity, making them suitable for heavy-duty applications.

c. Magnetic Guide Rails: Magnetic guide rails use magnetic fields to guide and control the movement of magnetic-equipped robots. They offer precise positioning and allow for non-contact guidance, minimizing wear and tear.

Benefits and Applications: Robot guide rails offer several advantages, including:

a. Improved Accuracy: Guide rails ensure consistent and precise robot movement, leading to accurate positioning and repeatability.

b. Increased Efficiency: By guiding the robot’s motion, guide rails minimize deviations and reduce the time required for repositioning or readjustment.

c. Enhanced Safety: The robot slider provides a secure and controlled path, preventing accidental collisions and ensuring the safety of both the robot and human operators.

d. Versatile Applications: Robot guide rails find applications in various industries, such as manufacturing, assembly, material handling, packaging, and logistics.

Integration with Robot Systems: Robot guide rails are designed to be compatible with different types of robots, including industrial robots, collaborative robots (cobots), and mobile robots. They can be customized and integrated into existing robotic systems or incorporated into new installations.

It’s important to choose the appropriate guide rail system based on the specific requirements of the robot and the application. Factors such as load capacity, speed, precision, environmental conditions, and the desired range of motion should be considered when selecting and implementing robot guide rails.

Examples of industries where robot guide rails are commonly used?

Robot guide rails are commonly used in various industries where precise and controlled robot movement is required. Here are some examples of industries where robot guide rails find applications:

Automotive Industry: Robot guide rails are extensively used in automotive manufacturing for tasks such as welding, painting, assembly, and material handling. They ensure the accurate positioning of robots along the assembly line, improving efficiency and quality.

Electronics and Electrical Industry: In the electronics industry, guide rails are employed for tasks like PCB assembly, soldering, and component placement. They enable robots to navigate complex circuit boards and ensure precise positioning during the assembly process.

Packaging and Logistics: In packaging and logistics applications, robot guide rails help automate tasks such as palletizing, pick-and-place operations, and conveyor systems. They ensure smooth and controlled movement of robots, optimizing the packaging process and enhancing productivity.

Pharmaceuticals and Medical Devices: Guide rails are used in the pharmaceutical and medical device industries for tasks like precision assembly, quality inspection, and packaging. They enable robots to handle delicate and sensitive components with accuracy and consistency.

Food and Beverage Industry: Robot guide rails have applications in food and beverage processing, including tasks like sorting, packaging, and material handling. They ensure hygienic and efficient movement of robots in compliance with food safety standards.

Aerospace and Aviation Industry: In the aerospace sector, guide rails are used for robotic applications such as drilling, riveting, and composite layup. They provide the necessary stability and precision for robotic systems operating on aircraft components.

Metal Fabrication: Guide rails are utilized in metal fabrication processes such as laser cutting, bending, and welding. They ensure precise positioning of robots for accurate metal processing and assembly.

Plastics and Rubber Industry: In plastic injection molding and rubber manufacturing, guide rails are employed for tasks like mold handling, part removal, and quality inspection. They enable robots to navigate the production line smoothly and perform tasks with precision.

These are just a few examples, and robot guide rails also have applications in many other industries. The versatility and benefits of guide rails make them valuable in industries that require reliable and controlled robot motion.

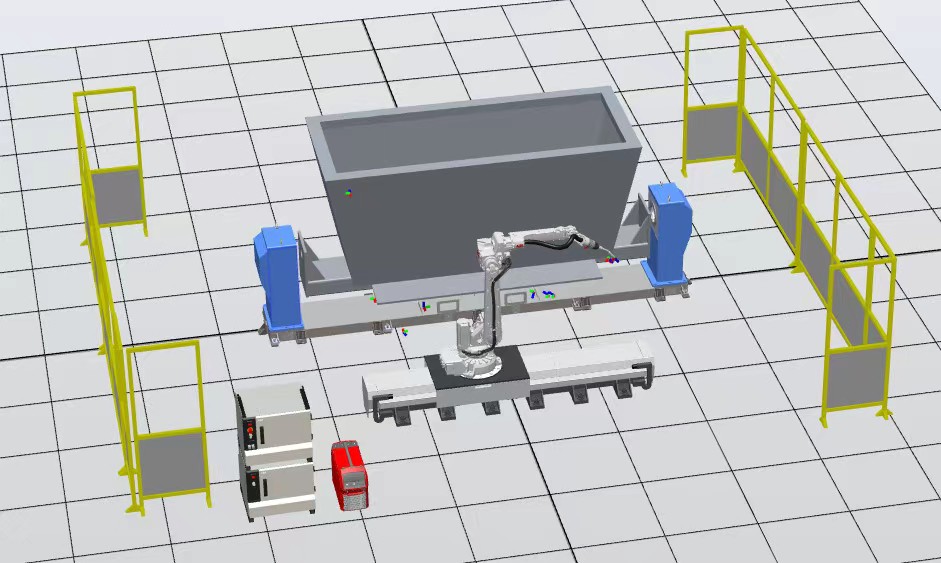

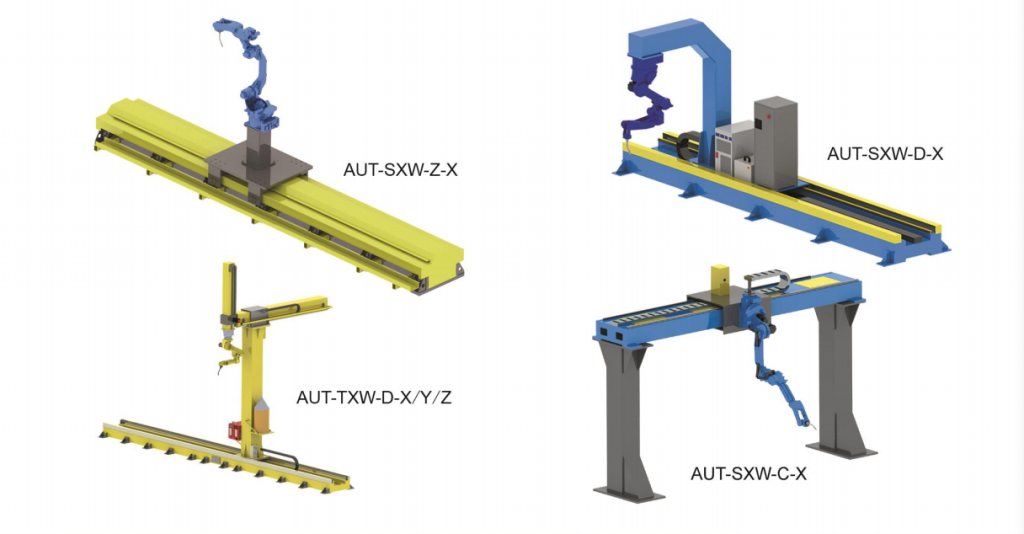

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System