Walk into any modern fabrication shop today, and the first thing that hits you isn’t just the smell of ozone—it’s the sight of massive robotic arms swinging with rhythmic precision. It’s an impressive sight, but for many veteran welders, it’s also a bit unsettling. As automation continues to reshape the manufacturing landscape, welding robots have become the primary example of how machines are stepping into roles once held exclusively by people.

We hear the buzzwords: efficiency, safety, and ROI. But behind the corporate optimism lies a very real human anxiety. Many people genuinely fear that these machines are here to replace them entirely. To understand how to navigate this transition, we need to look at why this fear exists and what the reality actually looks like on the shop floor.

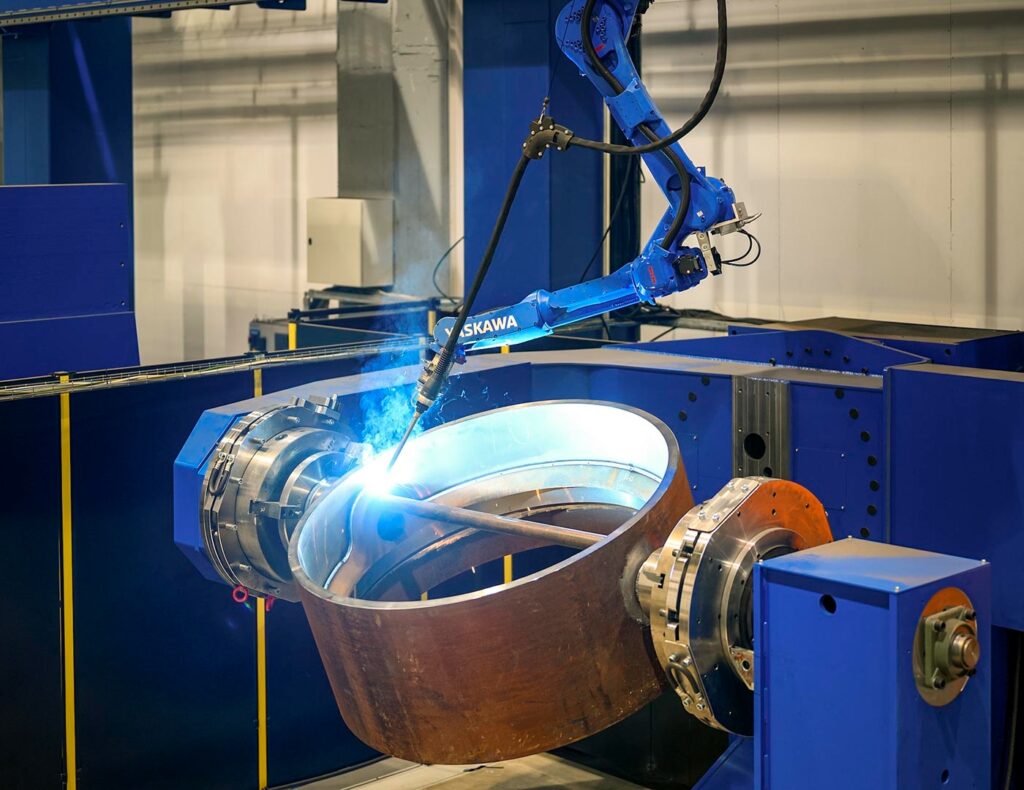

The Visual Impact of the “Robotic Takeover”

It’s easy to see why people are nervous. When a manual welding station is replaced by a complex robotic cell shielded by light curtains and safety fences, the visual impact is immediate. You aren’t just looking at a new tool; you’re looking at something that looks like it’s doing a human’s job autonomously.

This creates a powerful psychological effect. If a machine is doing the work you used to do, the natural conclusion is that your role is disappearing. It feels less like an upgrade and more like a displacement.

The Bottom Line: Economic Pressures

Let’s be honest: business leaders lean into robotics because the math works. In a cutthroat global market, robots deliver predictable advantages: they don’t get tired, they hit the same bead every single time, and they keep workers out of hazardous environments.

For a business owner focused on staying competitive, robots often seem like a straightforward solution. However, for the worker whose livelihood depends on that industrial employment, it feels like a direct threat to job security. The reality, though, is that the cost-savings from robots often keep a company viable enough to retain its workforce in other areas.

What Robots Actually Do (And What They Can’t)

There is a massive misconception that automation eliminates jobs entirely. In reality, welding robots are designed to take over the “three Ds”: Dull, Dirty, and Dangerous tasks. They are perfect for repetitive, high-strain work where human fatigue leads to errors.

But a robot is essentially a very expensive tool; it lacks human intuition. It cannot:

- Manage complex engineering challenges or creative problem-solving.

- Perform its own maintenance or advanced programming.

- Handle system integration or high-level quality inspection.

Ultimately, automation is changing the nature of work, not necessarily the amount of it.

Breaking the Cycle of Fear

Much of the “robot-phobia” stems from a lack of transparency. When management introduces automation without a clear plan or explanation, workers fill that information gap with speculation and fear.

We’ve seen this before. Whether it was the introduction of CNC machines or the first computers, technological shifts always trigger fears of job loss. History teaches us two things: jobs evolve rather than disappear, and new roles—like robot technicians—always emerge to fill the gap.

The Path Forward: Bridging the Skill Gap

The real threat to a worker isn’t the robot itself—it’s the gap between their current skills and what the new industry demands. In regions where retraining opportunities are scarce, the anxiety is highest.

So, how do we bridge this gap?

For Workers:

- Embrace lifelong learning and get trained in robot operation.

- Focus on problem-solving and analytical skills that machines can’t replicate.

For Companies:

- Communicate automation plans transparently and invest in employee training.

- Redesign roles to frame the robot as a partner, not a replacement.

Final Thoughts

The belief that welding robots will steal jobs is rooted in everything from visual impact to historical precedent. But the truth is more nuanced: automation changes how we work, but it doesn’t make humans obsolete. With the right approach to training and communication, welding robots can boost productivity while creating more valuable, safer opportunities for the people who run them.

Contact us right now!

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System