Welding Positioner Maintenance Checklist: How to Keep Your System Running at Peak Performance

In robotic and automated welding lines, a welding positioner does far more than rotate a workpiece. It directly affects weld quality, cycle time, and overall production stability. Yet in many factories, positioner maintenance is often reactive rather than planned—problems are addressed only after performance starts to drop.

A consistent maintenance routine helps extend equipment life, reduce unplanned downtime, and maintain stable welding quality. Below is a practical, experience-based checklist to help keep your welding positioner performing at its best.

Why Regular Welding Positioner Maintenance Matters

Over time, welding positioners are exposed to heat, spatter, vibration, and heavy loads. Even small issues—such as loosened bolts or poor lubrication—can lead to misalignment, unstable rotation, or inconsistent welding results.

Regular maintenance helps you:

-

Maintain precise rotation and positioning

-

Prevent premature wear of bearings and gearboxes

-

Reduce unexpected production stops

-

Protect the safety of operators and equipment

In short, good maintenance protects both productivity and investment.

Daily and Shift-Level Checks

Some of the most effective maintenance actions are also the simplest.

At the start of each shift, operators should visually inspect the positioner for:

-

Abnormal noise, vibration, or jerky movement

-

Oil or grease leakage around bearings and gearboxes

-

Excessive welding spatter buildup on rotating surfaces

It is also good practice to verify that emergency stop functions and limit switches respond correctly. These quick checks take only minutes but can prevent serious failures.

Weekly Mechanical Inspection

On a weekly basis, a closer mechanical inspection is recommended.

Pay attention to:

-

Bolt tightness on mounting plates, faceplates, and fixtures

-

Condition of bearings, shafts, and rotating joints

-

Abnormal backlash or uneven rotation during operation

If the positioner is handling heavy or off-center loads, checking balance and fixture alignment becomes even more important. Small deviations can quickly affect long-term performance.

Lubrication and Drive System Maintenance

Lubrication is one of the most common areas where problems begin.

Follow the manufacturer’s lubrication schedule for:

-

Slewing bearings

-

Gearboxes

-

Drive chains or gears (if applicable)

Using the correct lubricant—and not over-greasing—is critical. At the same time, inspect motors, reducers, and coupling components for overheating or unusual wear. A well-maintained drive system ensures smooth rotation and stable welding speed.

Electrical and Control System Checks

Welding positioners used in automated or robotic cells rely heavily on stable electrical and control systems.

Regularly inspect:

-

Cable connections for wear or looseness

-

Encoders and sensors for proper positioning feedback

-

Control panels and inverters for error messages or abnormal temperature

For robotic welding cells, confirm that positioner synchronization with the robot remains accurate. Even minor feedback errors can affect weld quality.

Periodic Load and Accuracy Verification

At longer maintenance intervals, it is wise to verify:

-

Actual load versus rated capacity

-

Rotation accuracy and repeatability

-

Braking performance under load

Overloading is a common cause of long-term damage. Ensuring that the positioner operates within its design limits helps avoid structural fatigue and premature failure.

Maintenance Records and Preventive Planning

One often overlooked step is documentation.

Keeping clear maintenance records allows you to:

-

Track wear patterns

-

Identify recurring issues

-

Plan preventive maintenance before failures occur

Many manufacturers find that a simple checklist combined with scheduled inspections significantly reduces downtime over time.

Keep Your Welding Positioner Performing Long Term

A welding positioner is a core component of any manual or robotic welding setup. With regular inspection, proper lubrication, and timely adjustments, it can operate reliably for years while maintaining high welding quality.

If you are unsure about maintenance intervals, load capacity, or upgrade options, working with an experienced equipment supplier can help you optimize both performance and service life.

Looking for reliable welding positioners or maintenance support?

Contact us for professional solutions tailored to your welding application.

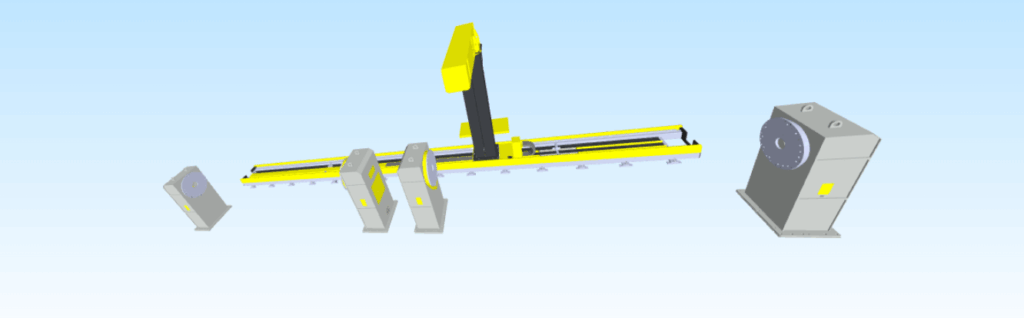

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System