In the age of Industry 4.0, industrial automation has become essential for manufacturers seeking to improve productivity, precision, and efficiency. One of the most valuable tools in modern automated operations is the robotic positioner. These devices play a crucial role in enhancing welding, assembly, and material handling processes. Below, we explore the top five benefits of using robotic positioners in industrial automation.

1. Enhanced Precision and Consistency

One of the primary advantages of robotic positioners is their ability to provide consistent and precise control over the movement and positioning of workpieces. This precision ensures that robots can perform tasks such as welding and assembly with remarkable accuracy, resulting in:

- Improved product quality: Reduced errors and defects.

- Consistent operations: Uniformity across multiple production runs.

- Minimized rework: Less time and cost spent on fixing errors.

By maintaining exact angles and positions, robotic positioners help achieve superior craftsmanship, even for complex tasks.

precision robotic positioners and consistent automation tools.

2. Increased Productivity and Efficiency

Robotic positioners significantly reduce production cycle times by optimizing the positioning of workpieces for robots. This automation allows simultaneous multi-tasking by:

- Rotating or moving the part while the robot performs tasks.

- Minimizing downtime caused by manual repositioning.

- Reducing setup times between processes.

With faster production cycles and fewer interruptions, manufacturers can boost overall output and reduce operational bottlenecks.

productivity-enhancing positioners and automation efficiency solutions.

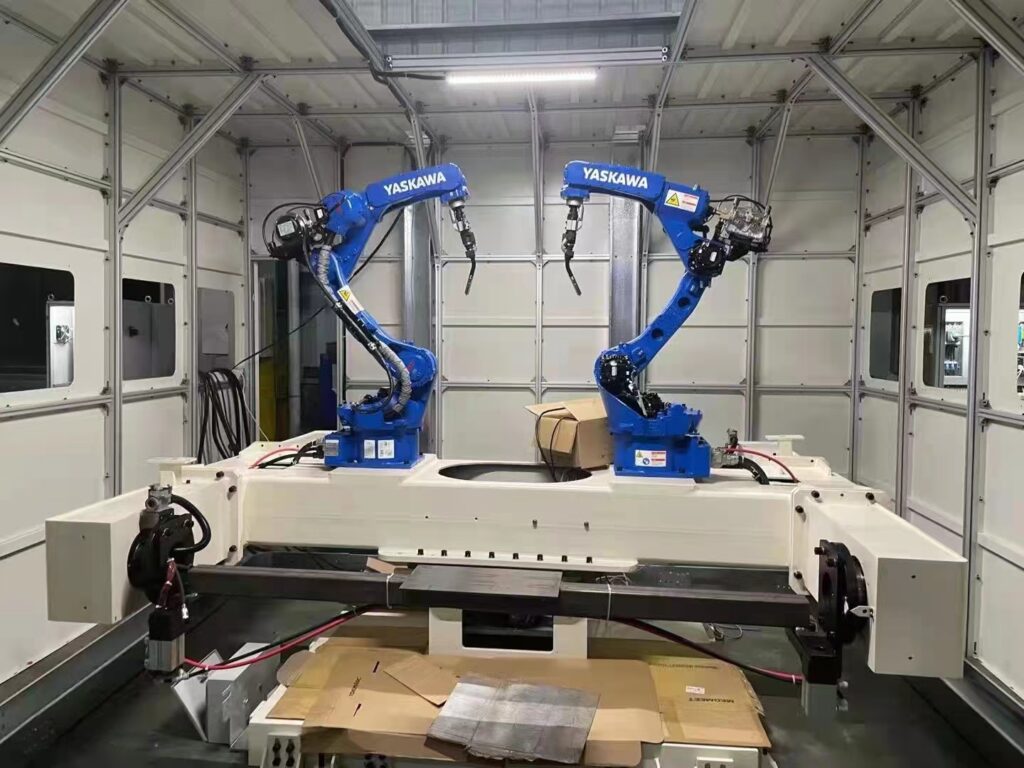

3. Greater Flexibility in Operations

Robotic positioners are designed to handle a wide variety of tasks and workpieces. This flexibility is achieved through features such as:

- Multi-axis movement: Rotation, tilt, and elevation adjustments.

- Compatibility: Integration with different types of robots and tools.

- Customizable configurations: Ability to adapt to various production requirements.

This versatility allows manufacturers to handle diverse projects and quickly switch between different tasks, providing an edge in dynamic production environments.

flexible robotic positioners and multi-axis industrial solutions.

4. Improved Safety for Workers

Industrial automation, including robotic positioners, reduces the need for human operators to handle hazardous tasks. This not only minimizes exposure to dangerous environments but also reduces workplace injuries by:

- Eliminating manual lifting and positioning: Robots handle heavy workpieces.

- Keeping operators away from welding arcs and heat zones: Robots manage tasks in high-risk areas.

- Enhanced safety features: Emergency stop functions and safety interlocks.

With robotic positioners handling dangerous and repetitive tasks, companies can maintain a safer working environment.

industrial safety solutions and worker safety in automation.

5. Cost Savings and Long-Term ROI

While robotic positioners may require an upfront investment, the long-term financial benefits are substantial. These include:

- Reduced labor costs: Fewer manual operations.

- Lower material waste: Precision operations reduce scrap rates.

- Increased equipment longevity: Optimized working conditions for robotic systems.

Over time, these cost efficiencies contribute to a significant return on investment (ROI), making robotic positioners a smart financial decision for manufacturers.

cost-effective industrial automation and ROI with robotic positioners.

Conclusion

The adoption of robotic positioners in industrial automation offers numerous advantages, including enhanced precision, productivity, flexibility, safety, and cost savings. By leveraging these benefits, manufacturers can remain competitive and meet the growing demands of the modern market.

Whether you’re considering robotic positioners for welding, assembly, or material handling, investing in these advanced automation tools is a step toward achieving smarter, more efficient production processes.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System