What Exactly is a Robot Welding Positioner?

Think of a robot welding positioner as a super-helpful rotating tray in a kitchen, but for industrial use. You know how a lazy Susan in the kitchen makes it easy to reach different condiments? Well, a robot welding positioner does something similar for manufacturing. Its main job is to adjust the position and orientation of workpieces, making the welding and other manufacturing processes much easier.

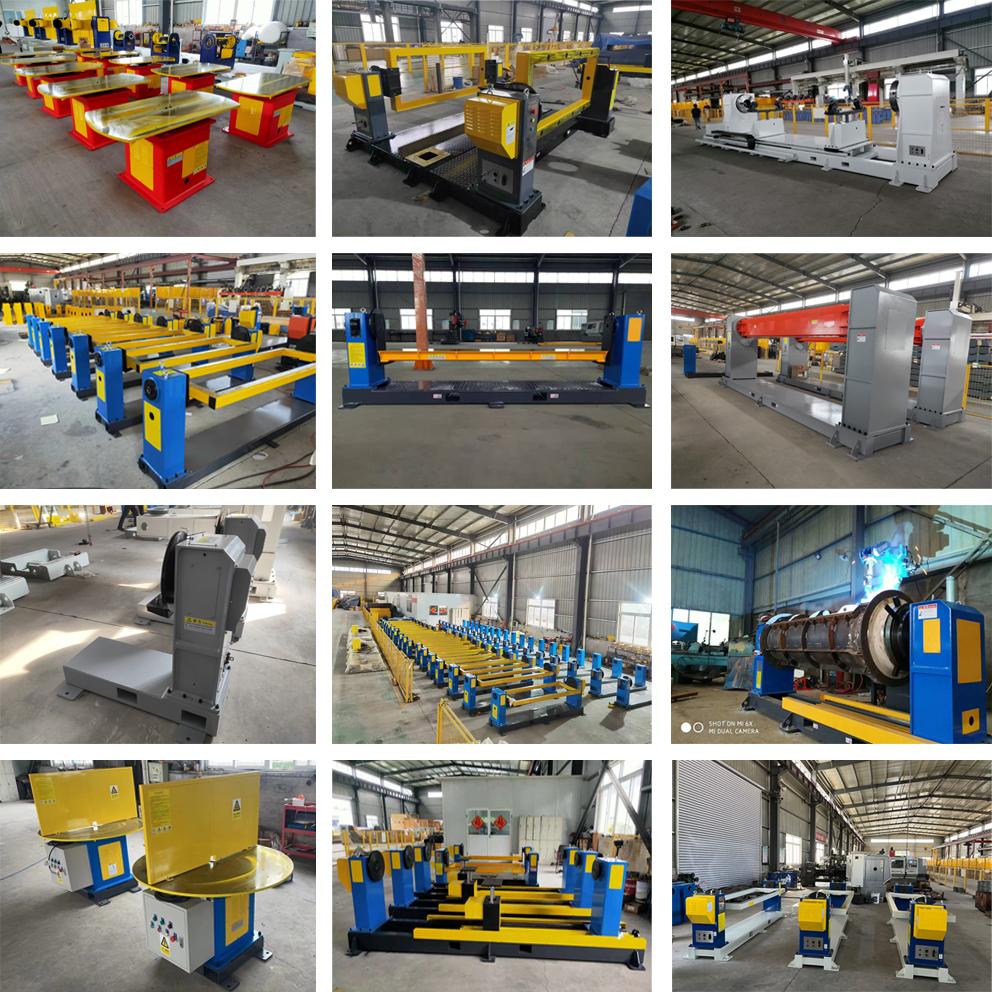

The basic structure of a robot welding positioner consists of three main parts. First, there’s the worktable, which is where the workpiece is placed. It’s like the surface of that lazy Susan where the items are put. Then, there’s the drive device. This is the “muscle” of the positioner, providing the power to rotate or flip the worktable. It could be powered by motors, which come in different types like servo motors for high – precision movements. Finally, there’s the control system. This is like the “brain” of the positioner. It determines how the worktable moves, setting the speed, angle of rotation, and the sequence of movements. Whether it’s making a simple 360 – degree rotation or a complex series of flips and tilts, the control system is in charge. With these components working together, the robot welding positioner can transform the way manufacturing processes are carried out.

In the Welding Scene

Let’s take the example of a stainless – steel pipe – welding factory. Before they introduced the welding positioner, the workers had a really tough time. They were dealing with long, heavy stainless – steel pipes. To weld these pipes, the workers had to constantly move around the workpiece. They often had to perform 仰焊 (overhead welding) and 立焊 (vertical welding) positions, which are not only physically demanding but also very difficult to do accurately. As a result, the quality of the welds was inconsistent, with a high rate of defects like porosity and uneven bead formation.

After installing the welding positioner, the situation changed dramatically. The positioner could rotate the pipes, bringing the weld seams to the horizontal or 船形 (flat – fillet – like, also known as the “boat – shaped” position in welding terms) positions. This made the welding process much easier. The welders could now work in a more comfortable position, and the quality of the welds improved significantly. The defect rate dropped from about 15% to less than 5%. Moreover, the workers’ labor intensity was greatly reduced. They no longer had to bend, stretch, or stand in awkward positions for long periods, which increased their work efficiency and also reduced the risk of work – related injuries.

In the Assembly Scene

Think about an automobile engine assembly line. Engines are complex pieces of machinery with numerous components that need to be precisely assembled. In the past, without a welding positioner, workers often had to struggle to reach certain parts of the engine block or components. They might have to bend over for long periods to install parts at the bottom, or stand on tiptoes to reach the upper parts. This not only caused physical fatigue but also increased the risk of human error, which could lead to misaligned parts or loose connections.

With a welding positioner in place, the engine components can be adjusted to the most convenient height and tilt angle. For example, when installing the cylinder head onto the engine block, the positioner can tilt the engine block slightly so that the workers can easily align and fasten the bolts without having to strain their bodies. This has increased the assembly speed by about 30% in many factories. Workers can complete more assemblies in a day, and the overall quality of the assembled engines has also improved due to more accurate positioning during the assembly process.

In the Detection Scene

Consider an automotive parts manufacturing company that produces various engine components such as crankshafts and camshafts. These parts need to be thoroughly inspected for any cracks, defects, or dimensional inaccuracies before they can be used in the final products. Before using a welding positioner, the detection process was somewhat limited. Visual inspection methods often couldn’t cover all areas of the parts, especially those with complex shapes. For example, on a crankshaft, there are many curves and hidden areas that are difficult to access for inspection. As a result, some defects might go unnoticed, which could lead to engine failures later on. Once the welding positioner was introduced, it could rotate the parts 360°. When combined with advanced visual detection equipment like high – resolution cameras and 3D scanners, it could provide a comprehensive inspection of the entire part. The cameras could capture images from all angles as the part rotated, and the 3D scanners could create detailed models to check for any dimensional deviations. This has significantly improved the detection accuracy. In one case, a company was able to reduce the number of defective parts reaching the next production stage by 40%, saving a great deal of cost in terms of rework and product recalls.

Key Features of High – Quality Welding Positioners

High – quality welding positioners are a cut above the rest, boasting several key features that make them stand out in the industrial landscape. These features are not just technical jargon; they’re the real deal that can transform a production line.

Wide Load Adaptability

Welding positioners come in a wide range of load – bearing capacities, which is super important. Whether you’re dealing with tiny 50 – kg small – scale hardware components like the screws and brackets used in electronic devices or massive over – 100 – ton heavy – duty machinery parts such as the large – scale engine blocks in ships or construction equipment, there’s a welding positioner for the job.

For instance, in a small – scale metal – working shop that mainly produces decorative metal handicrafts, a light – duty 50 – kg welding positioner is more than sufficient. It can easily handle the small metal pieces, allowing for smooth rotation and precise positioning during the welding process. On the other hand, in a large – scale ship – building yard, where workers are welding massive steel plates that weigh dozens of tons, a heavy – duty welding positioner with a load – bearing capacity of hundreds of tons is essential.

Selecting a welding positioner with the right load – bearing capacity according to the workpiece’s weight is crucial. Using a positioner with insufficient load – bearing capacity is like trying to carry a huge backpack with a flimsy string – it’s bound to break. In contrast, choosing a positioner with far – exceeding load – bearing capacity is like using a sledgehammer to crack a nut, a waste of resources. So, make sure to match the positioner’s load – bearing capacity to the workpiece’s weight for optimal performance.

Precise Accuracy Control

When it comes to high – quality Welding turntable, precise accuracy control is non – negotiable. These advanced machines achieve this precision through a combination of servo motors and worm – gear drives.

Servo motors are like the “precision athletes” of the motor world. They can quickly and accurately respond to control signals, ensuring that the worktable rotates or tilts with pinpoint accuracy. The worm – gear drive, on the other hand, provides stable and precise transmission. It has a high reduction ratio, which means it can slow down the rotation speed while increasing the torque, resulting in smooth and accurate movements.

The specific accuracy data of these high – quality welding positioners is truly impressive. The flipping angle accuracy can reach ±0.1°, and the repeat positioning error is ≤0.05mm. To put this into perspective, this level of accuracy is equivalent to the thickness of a few strands of hair. In industries like aerospace manufacturing, where the slightest deviation can lead to catastrophic consequences, this high – level accuracy is a must. For example, when welding the components of an aircraft engine, the precise alignment and welding ensured by the high – accuracy welding positioner are crucial for the engine’s performance and safety. This high – level accuracy control ensures consistent processing quality, reducing the number of defective products and improving production efficiency in the long run.

Strong Compatibility

One of the most remarkable features of high – quality Automated welding positioner is their strong compatibility. They can work in harmony with other industrial equipment such as robots and machine tools, and this is made possible through industrial buses for signal intercommunication.

Let’s take the example of a welding robot working in tandem with a welding positioner. When the welding robot starts to work, the welding positioner can simultaneously adjust the workpiece’s posture. As the robot moves along the welding path, the positioner rotates or tilts the workpiece to ensure that the weld seam is always in the most suitable position for welding. This “machine – to – machine collaboration” significantly improves production efficiency. In an automotive manufacturing plant, for example, when welding the body parts of a car, the welding robot and the welding positioner work together seamlessly. The positioner adjusts the position of the car body parts, and the robot performs the welding operation, greatly speeding up the welding process and improving the quality of the welds. This compatibility not only enhances production efficiency but also enables more complex and precise manufacturing processes, making it a highly sought – after feature in modern industrial production.

How to Choose and Use a Welding Positioner

Selection Points

When choosing a welding positioner, there are a few key points to keep in mind. First and foremost, consider the load and working conditions. If you’re dealing with heavy – duty materials like stainless – steel or carbon – steel workpieces, you’ll need a welding positioner with a high – strength welded frame. This is because these materials are often heavy, and a flimsy frame won’t be able to support them properly. For example, in a steel – structure manufacturing factory that produces large – scale building components made of thick carbon – steel plates, a high – strength frame is essential to ensure the safe and stable operation of the welding positioner.

Also, take the working environment into account. If the positioner will be used in a dusty or oily environment, such as in an automotive repair shop or a foundry, you should opt for a model with an IP65 or higher protection rating. This level of protection can prevent dust and oil from getting inside the device, which could otherwise cause damage to the internal components and reduce the lifespan of the positioner.

Another important aspect is the control method. For simple processes, a manual knob – controlled welding positioner might be sufficient. This is like using a basic hand – operated tool. It’s easy to use and doesn’t require a lot of technical knowledge. For instance, in a small – scale metal – working workshop that only does simple welding jobs, a manual – controlled positioner can get the job done. However, for complex scenarios that involve multiple devices working together, like in an automated production line where a welding positioner needs to work in sync with a welding robot, a PLC – controlled positioner is the way to go. With PLC control, you can preset programs and recall them with just one button. This not only saves a lot of time in the debugging process but also ensures more accurate and efficient operation.

Daily Maintenance

Daily maintenance of a welding positioner is crucial to keep it in top – notch condition and prevent unexpected breakdowns. Let’s start with the weekly checks. Every week, make sure to inspect the lubrication of the transmission components. Just like you need to oil the hinges of a door to keep it opening and closing smoothly, the transmission components of the welding positioner need proper lubrication to function well. Lack of lubrication can cause excessive friction, which in turn can lead to wear and tear of the parts, and eventually, a breakdown.

On a monthly basis, it’s important to calibrate the angle sensor. The angle sensor is like the “eyes” of the welding positioner when it comes to positioning. Over time, its accuracy might drift, especially with frequent use. Calibrating it regularly ensures that the positioner can accurately adjust the workpiece to the desired angle, maintaining the quality of the welding or assembly process.

Quarterly maintenance should include tightening the bolts. During the operation of the welding positioner, vibrations can cause the bolts to loosen gradually. If left unattended, loose bolts can lead to instability of the device. In extreme cases, it could even cause the workpiece to fall off during operation, which is not only dangerous but also costly in terms of damaged products and potential production delays. So, taking the time to perform these regular maintenance tasks can significantly extend the lifespan of the welding positioner and keep your production line running smoothly.

Conclusion

In conclusion, the robot welding positioner is an unsung hero in the manufacturing industry. It might not be as flashy as some other high – tech equipment, but its contributions to production efficiency and product quality are undeniable.

For businesses aiming to enhance their competitiveness in the market, paying attention to the selection and proper use of welding positioners is crucial. By choosing a welding positioner that suits their production needs in terms of load – bearing capacity, working environment, and control methods, and by performing regular maintenance, companies can significantly improve their production processes. They can expect higher – quality products, fewer defects, and increased production speed. This not only reduces production costs in the long run but also helps build a good reputation in the market. So, don’t underestimate the power of this small but mighty device. Embrace the potential of the robot welding positioner and take your manufacturing operations to the next level.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System