Introduction

In robotic welding and automated fabrication, handling large, heavy, and geometrically complex workpieces is one of the biggest challenges manufacturers face. Poor positioning not only slows down cycle times but also leads to inconsistent weld quality, higher rework rates, and increased labor dependency.

This is where L-Type welding positioners and Skyhook positioners deliver measurable value. More than just auxiliary equipment, these positioners play a critical role in improving welding efficiency, process stability, and overall return on investment (ROI) in modern automated welding cells.

This article explores how L-Type and Skyhook positioners generate ROI when processing complex workpieces, and why they are increasingly adopted in high-mix, large-scale manufacturing environments.

Understanding the Challenges of Complex Workpieces

Complex workpieces typically involve one or more of the following characteristics:

- Large size and heavy weight

- Irregular geometry or asymmetrical load distribution

- Multi-surface welding requirements

- Tight quality tolerances

Without proper positioning, robots must compensate through awkward torch angles, extended reach, or multiple re-clamping operations. This results in:

- Longer cycle times

- Increased programming complexity

- Higher risk of weld defects

- Reduced robot lifespan due to unfavorable load conditions

To address these issues, manufacturers turn to advanced multi-axis welding positioners that can synchronize motion with robotic welding paths.

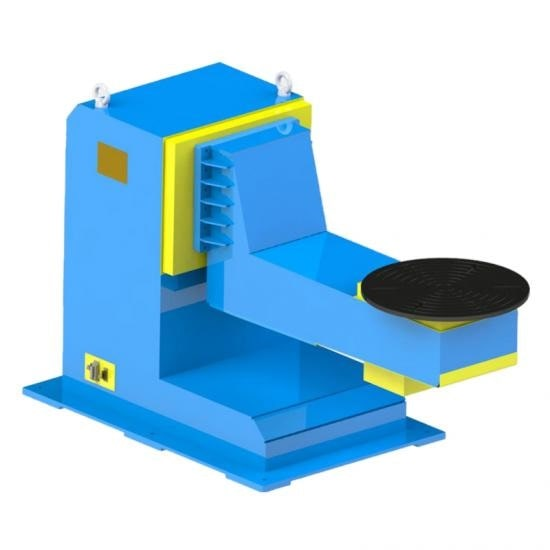

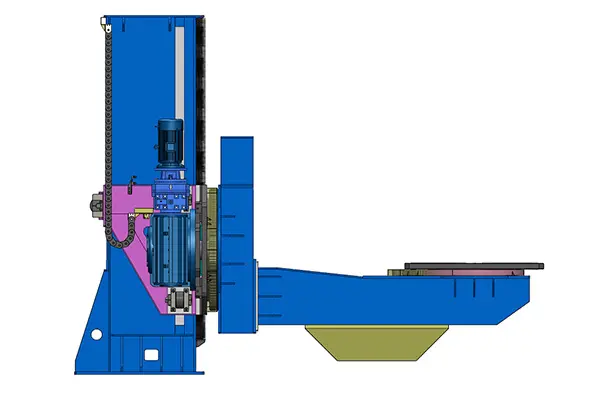

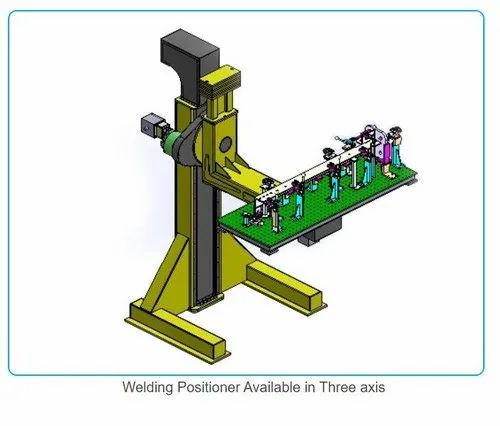

What Is an L-Type Welding Positioner?

An L-Type welding positioner features a vertical column combined with a horizontal rotating table, forming an “L” shaped structure. This configuration allows:

- Vertical elevation of the workpiece

- 180° rotation on the main axis

- Continuous 360° rotation on the secondary axis

Key Advantages

- Excellent load capacity for large components

- Stable center-of-gravity control

- Flexible height adjustment for optimal welding posture

L-Type positioners are particularly suitable for box structures, frames, pressure vessels, and fabricated assemblies that require multiple welding angles without repositioning the robot.

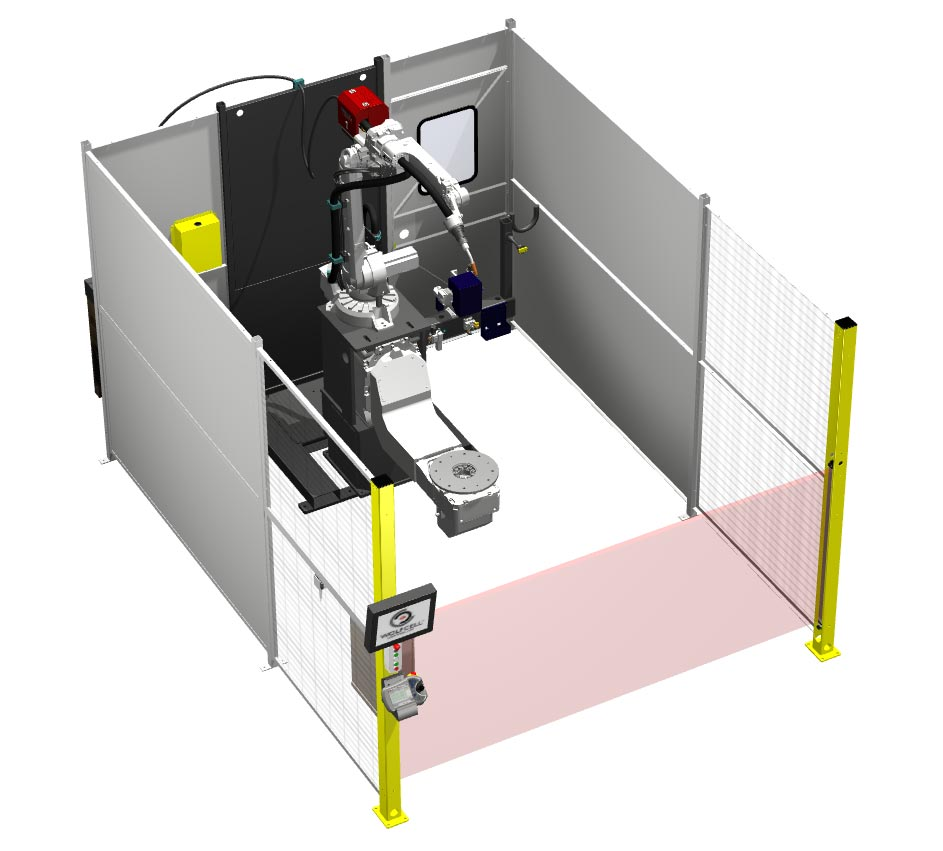

What Is a Skyhook Positioner?

A Skyhook positioner suspends the workpiece from above, leaving the underside completely accessible for welding. Unlike floor-mounted systems, Skyhook designs free up valuable floor space and allow full access around complex geometries.

Key Advantages

- Maximum accessibility to all weld seams

- Ideal for irregular or asymmetrical parts

- Reduced fixture complexity

Skyhook positioners are often used in applications where gravity-assisted positioning improves weld quality and where traditional turntables are impractical.

How L-Type and Skyhook Positioners Deliver ROI

1. Reduced Cycle Time

By enabling continuous rotation and elevation, these positioners allow robots to weld in optimal positions without stopping for reorientation. Weld seams can be completed in a single setup, significantly reducing non-productive time.

In many automated cells, manufacturers report cycle time reductions of 15–30% after integrating advanced positioners.

2. Improved Weld Quality and Consistency

Maintaining the correct welding posture—especially flat or horizontal welding—has a direct impact on penetration, bead appearance, and defect rates.

L-Type and Skyhook positioners allow:

- Stable torch angles

- Consistent heat input

- Reduced spatter and distortion

This leads to lower rework rates and higher first-pass yield, which directly improves ROI.

3. Lower Labor Dependency

Manual repositioning of heavy workpieces is time-consuming, unsafe, and costly. Automated positioners eliminate the need for cranes, forklifts, or manual handling during welding operations.

Benefits include:

- Reduced labor costs

- Improved workplace safety

- Better utilization of skilled welders

4. Faster Programming and Changeovers

Modern L-Type and Skyhook positioners can be fully synchronized with welding robots, allowing coordinated motion through offline programming.

This reduces:

- Programming time

- Debugging cycles

- Downtime during product changeovers

For manufacturers producing multiple product variants, this flexibility significantly boosts overall equipment effectiveness (OEE).

5. Scalable Automation Investment

Unlike fixed fixtures, advanced positioners can be reused across multiple projects and integrated with different robot models or welding processes.

This scalability ensures:

- Long equipment lifespan

- Lower cost per welded part over time

- Strong long-term ROI

Choosing Between L-Type and Skyhook Positioners

| Application Requirement | Recommended Solution |

| Heavy, box-type structures | L-Type Positioner |

| Irregular or asymmetrical parts | Skyhook Positioner |

| Limited floor space | Skyhook Positioner |

| High payload with stable geometry | L-Type Positioner |

In many advanced welding cells, both types are used together to handle different product families efficiently.

Conclusion

L-Type and Skyhook positioners are not just accessories—they are strategic investments that directly impact productivity, quality, and automation efficiency. By reducing cycle times, improving weld consistency, and minimizing labor involvement, these positioners deliver a strong and measurable ROI, especially when working with complex and heavy workpieces.

For manufacturers looking to scale robotic welding automation while maintaining flexibility and cost control, integrating the right positioner solution is a critical step. Contact us to explore how L-Type and Skyhook positioners can be tailored to your specific welding applications and production goals.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System