Product Overview

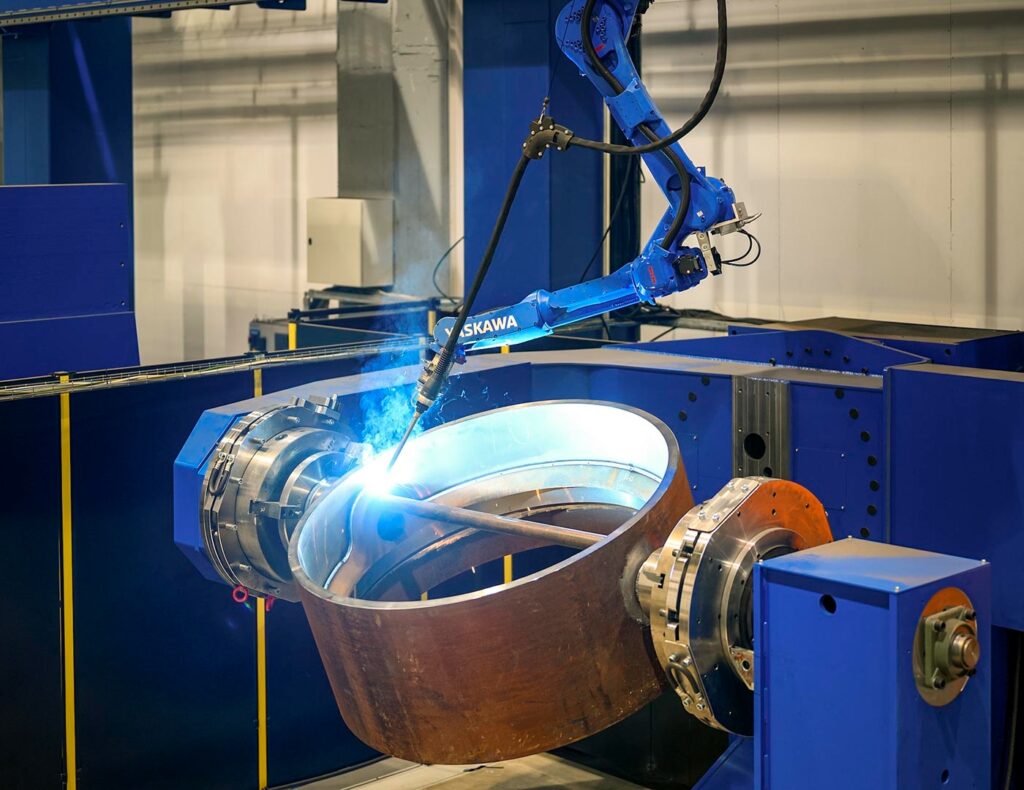

The Yaskawa AR2010 is a long-reach industrial welding robot developed for large-scale and heavy-duty welding applications. Designed to overcome the working envelope limitations of compact models, it provides extended reach and high load stability while maintaining Yaskawa’s renowned motion accuracy and reliability.

Powered by the YRC1000 controller, the AR2010 integrates seamlessly with high-output welding power sources and automated production lines, making it an ideal choice for industries handling oversized components and continuous welding operations.

Technical Parameter

| Item | Specification |

| NUMBER OF AXES | 6 |

| PAYLOAD | 12 kg (9 kg on U-axis for specific scenarios) |

| MAX. WORKING RANGE | 2010 mm |

| REPEATABILITY | 0.03 mm (per ISO 9283 standard); 0.08 mm (per JIS B 8432 standard) |

| WEIGHT | 260 kg |

| POWER SUPPLY | 2.0 KVA |

| MAXIMUM SPEED S AXIS | 210 °/s |

| MAXIMUM SPEED L AXIS | 210 °/s |

| MAXIMUM SPEED U AXIS | 220 °/s |

| MAXIMUM SPEED R AXIS | 435 °/s |

| MAXIMUM SPEED B AXIS | 435 °/s |

| MAXIMUM SPEED T AXIS | 700 °/s |

| MOUNTING OPTIONS | Ceiling, Wall, Floor, Inclined |

Performance Advantages

Long Reach for Oversized Workpieces

With a working range of up to 2010 mm, the AR2010 enables full weld coverage on large components without frequent repositioning. This significantly improves efficiency when welding long seams or wide structures, making it well-suited for heavy fabrication tasks.

Robust Structure for Heavy Welding

Its reinforced body design supports stable, round-the-clock operation in high-load conditions. When paired with powerful welding machines such as the YD500GS, the AR2010 handles thick-plate welding tasks that exceed the capacity of compact welding robots.

Reliable Accuracy on Large Weldments

Despite its extended reach, the AR2010 maintains a repeatability of 0.03 mm (ISO 9283). Yaskawa’s advanced motion control algorithms ensure smooth, continuous paths across large workpieces, reducing cumulative deviation and improving weld consistency.

Adaptable System Integration

The robot supports flexible mounting configurations, including inclined installation, allowing easy adaptation to complex workshop layouts. Multiple industrial communication protocols—such as Ethernet/IP and Profibus—enable smooth integration into automated welding lines and factory networks.

Typical Application Areas

The AR2010 is widely used in industries where large components and long weld seams are common, including:

- Heavy Equipment Manufacturing: Excavator arms, crane structures, machinery frames

- Shipbuilding: Hull panels, deck assemblies, marine components

- Aerospace Manufacturing: Wing structures, fuselage frames, engine supports

- Steel Fabrication: Bridges, industrial frameworks, rail infrastructure

- Commercial Vehicle Production: Truck chassis, bus frames, heavy-duty exhaust systems

Why Work with Us

- Genuine Yaskawa robots and original components only

- Fast delivery and local technical support to reduce production downtime

- Experienced automation engineers for turnkey welding line integration

- Proven expertise in customized robotic welding solutions for large parts

Welding Robot FAQ | Industrial Robot Solutions

Q1: What does a standard Yaskawa welding robot include?

A: A standard Yaskawa robot package typically includes:

- Yaskawa industrial robot arm

- Robot control cabinet (4 m or 5 m cable between robot and controller)

- Teaching pendant with 8 m cable

- Complete operation manuals and documentation

If the standard cable length does not meet on-site requirements, extension cables can be provided.

Q2: What is a welding robot workstation?

A: A welding robot workstation is a fully automated welding production system consisting of one or more industrial robots and auxiliary equipment.

According to different production needs, a workstation may include:

- Welding power source and welding system

- Welding positioners

- Robot guiderails / linear tracks/robot silder

- Fixtures and tooling

- Safety fence, light curtain, or safety scanner

- Electrical control system

This solution improves welding efficiency, consistency, and safety.

Q3: Can a welding robot handle parts with poor tolerance?

A: Yes. For parts with inconsistent dimensions or poor tolerance, the welding robot can be equipped with:

- Laser seam tracking system

- Touch sensing (wire sensing)

- COMARC arc tracking system

These technologies allow the robot to automatically detect and track the welding seam, ensuring stable weld quality.

Q4: What after-sales service do you provide?

A: We provide 24/7 online technical support via email or WhatsApp.

Our engineers assist with:

- Installation and commissioning

- Programming guidance

- Troubleshooting and maintenance

Q5: What is your delivery time?

A:In-stock products: 5–10 working days,Out-of-stock or customized solutions: 15–20 working days

Delivery time may vary depending on order quantity and configuration.

Q6: What is the warranty period for your robot systems?

A: We offer a one-year warranty for the equipment, along with lifetime technical support and maintenance service.

Q7: Do you have your own factory?

A: Yes. Our factory is located in Jining City, Shandong Province, China.

We specialize in manufacturing robot peripheral equipment, including:

- Welding positioners

- Robot linear tracks (7th axis)

- Gantry systems

- Torch cleaning stations

Q8: Do you provide customized robot automation solutions?

A: Yes. We provide customized industrial robot automation solutions based on customer products, welding processes, and production requirements.

Q9: What products and solutions can you supply?

A: Our main products include:

- Industrial welding robots

- Welding positioners

- Robot linear sliders and guide rails

- Gantry robot systems

- Robot welding cells and workstations

- Welding accessories and automation components

Q10: How are welding robots packed for shipment?

A: We offer professional export packaging solutions, including:

- Wooden crate packaging

- Vacuu-sealed packing

- Moisture protection with desiccants

- Packaging methods can be customized according to customer requirements and transportation conditions.

Conclusion

The Yaskawa AR2010 welding robot is a powerful solution for manufacturers seeking reliable automation for large-scale welding applications. Its extended reach, structural stability, and high-precision motion control make it an excellent choice for improving weld quality, production efficiency, and long-term operational reliability.

Contact us today to explore how the AR2010 can be integrated into your welding automation system.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System