Description

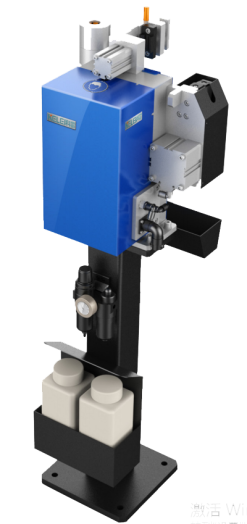

Maintaining Welding Excellence: Introducing the Automated Torch Cleaning Device

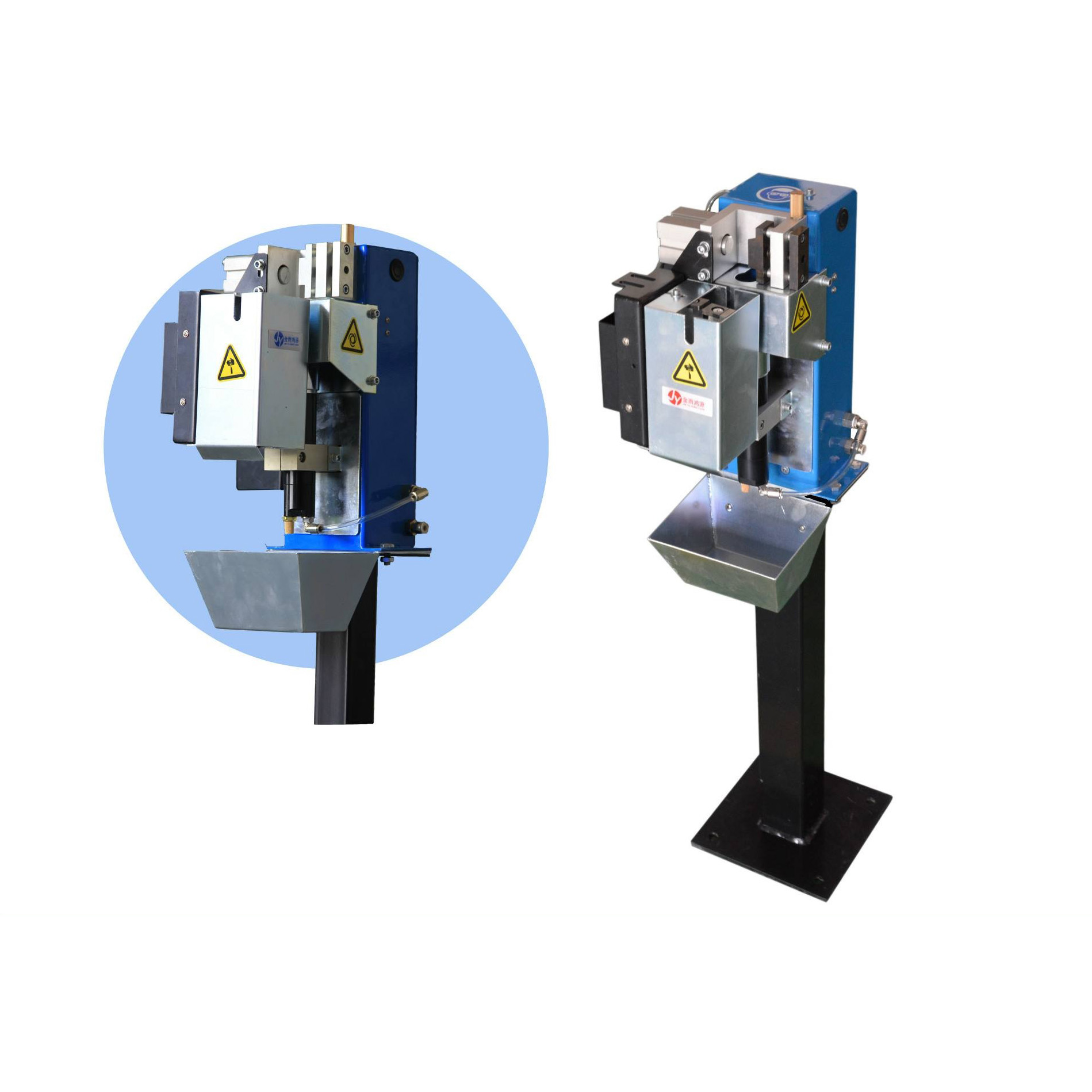

Welding robot torch cleaning station with 1-year warranty Can be integrated with different brands of welding robots, only need to change reamer

Ensuring the optimal performance of your welding equipment is crucial for consistent, high-quality results. That’s where our innovative Automated Torch Cleaning Device comes into play, revolutionizing the way you approach torch maintenance in your welding operations.

Designed to streamline and simplify the torch cleaning process, this state-of-the-art device leverages advanced automation to keep your welding torches in peak condition. Gone are the days of manual cleaning and the associated downtime – our solution takes care of the task efficiently and reliably, allowing you to focus on your core welding activities.

Key features and benefits of the Automated Torch Cleaning Device:

- Consistent Cleaning: Precise, programmed cleaning cycles ensure thorough and uniform removal of spatter, residue, and buildup on your welding torches.

- Improved Productivity: Automated cleaning reduces manual intervention and minimizes equipment downtime, boosting your overall welding productivity.

- Enhanced Weld Quality: Properly maintained torches deliver superior arc performance, leading to higher-quality welds and reduced rework.

- Increased Torch Lifespan: Regular, automated cleaning extends the service life of your welding torches, reducing replacement costs over time.

- Intuitive Operation: User-friendly controls and integration with your welding workflow make the cleaning device easy to adopt and incorporate into your existing processes.

Experience the transformative power of automated torch cleaning and take your welding operations to new heights of efficiency and excellence. Contact us today to learn more about how our Automated Torch Cleaning Device can optimize your welding productivity and quality.

.

Advantages of gun cleaning station:

1、Automatically complete the process of clearing the gun, no need for manual operation

2、Remove hard-to-remove welding slag spatters

3. Prevents contamination-related quality deviations in welding.

4、Improve the service life of welding torch and conductive nozzle.

5、Close-closed oil spraying compartment pre-spattering agent sprayed on the ground and equipment

6、Equipped with TCP point pointer for robot, convenient for debugging.

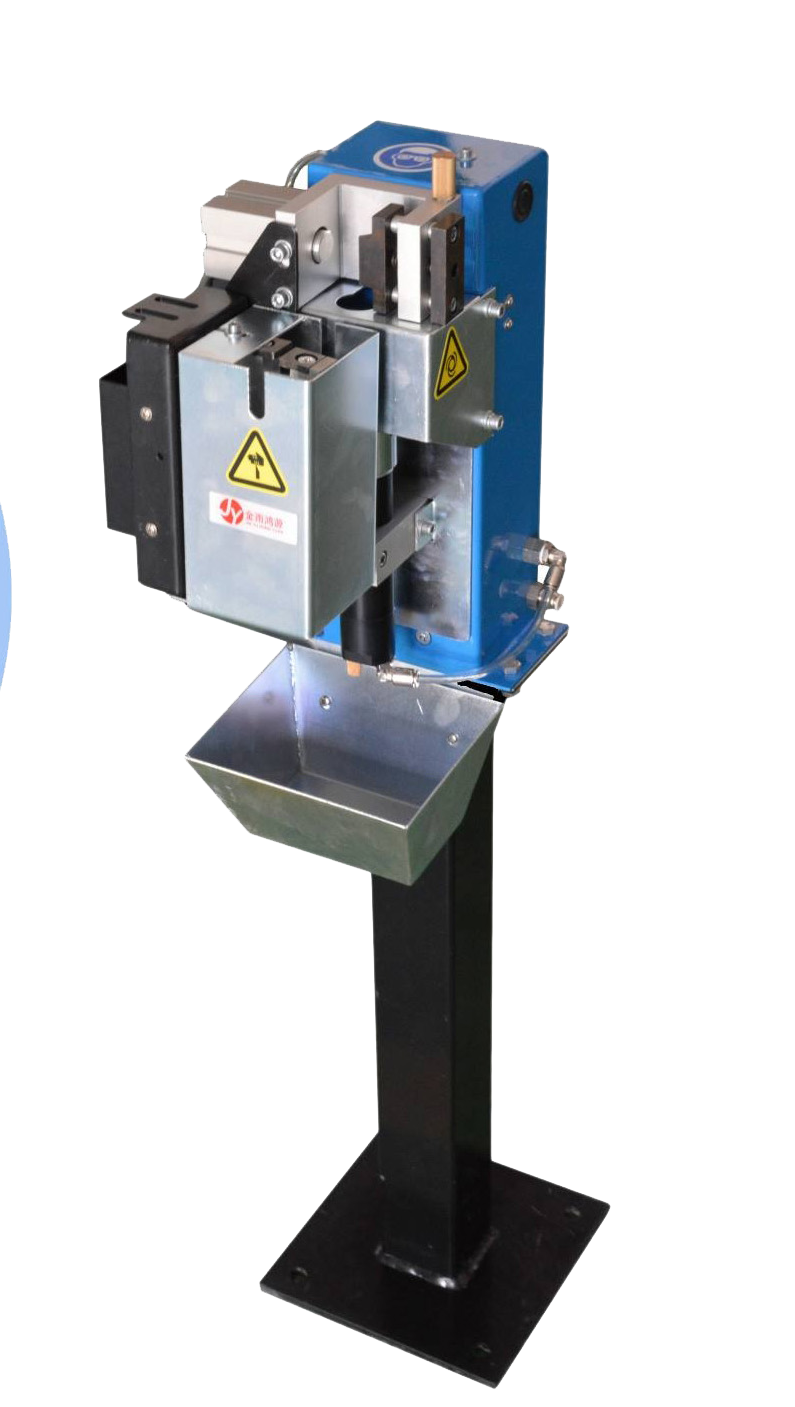

7、Three in one (cleaning, wire cutting, oiling), cleaning the welding torch time of about 5 seconds

- Automatic gun cleaning station is designed for robotic and automatic welding guns with automatic welding systems The gun cleaning station is controlled by the robot, which also provides the corresponding feedback signals to the robot. The device also provides feedback to the robot.

- The gun cleaning station uses reamer rotation to remove welding slag and contaminants from the gun tip and gun nozzle.

- The gun cleaning station is equipped with a complete oil spray structure, and the gun tip can be sprayed with anti-spatter fluid after the gun has been cleaned.

- This reduces the probability of re-adhesion of welding slag. Also equipped with an automatic wire-cutting device, which is triggered by the machine It is triggered electrically by the robot controller or mechanically by the welding gun.

Advantages

- Automatic Cleaning: A torch cleaning station can automatically clean the welding torch, removing any spatter or debris that may have accumulated during the welding process. This ensures that the torch remains clean and performs optimally throughout the welding process.

- Consistent Cleaning: A torch cleaning station can provide consistent cleaning of the welding torch, ensuring that the torch is cleaned to the same standard every time. This helps to maintain weld quality and consistency.

- Reduced Downtime: By automating the cleaning process, a torch cleaning station can reduce downtime between welds. This saves time and increases productivity, as the robot can continue welding without interruption.

- Improved Torch Life: Regular cleaning of the welding torch can help to extend its life, reducing the need for replacement and saving money in the long run.

- Enhanced Safety: A torch cleaning station can improve safety in the welding process by reducing the risk of spatter buildup on the welding torch. This can help to prevent the risk of fire or other hazards that could occur if the torch is not properly maintained.

- Customizable Options: Some torch cleaning stations offer customizable options, such as the ability to adjust the cleaning frequency or the type of cleaning method used. This allows for greater flexibility and customization depending on the specific needs of the welding process.

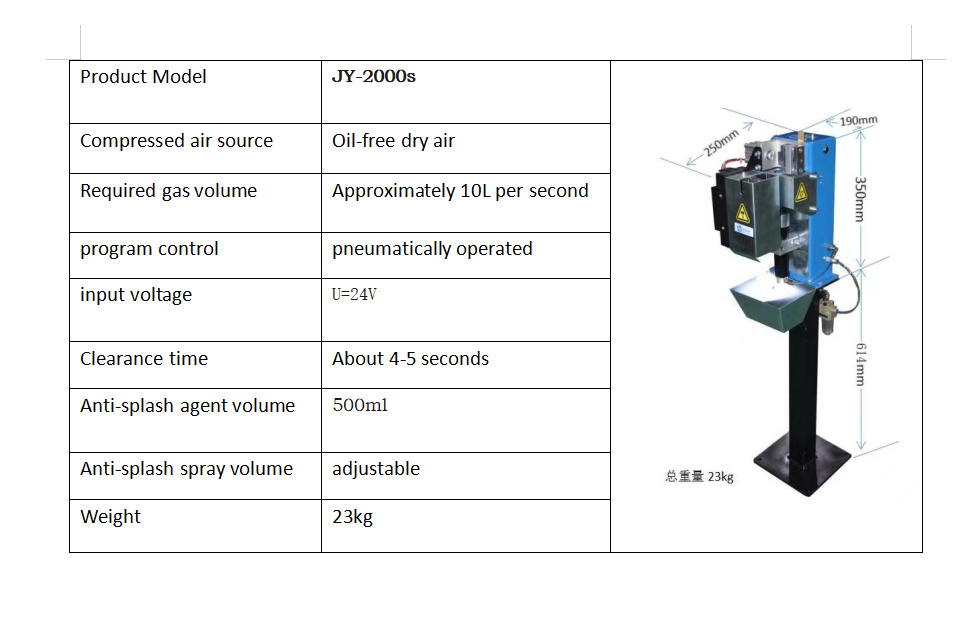

Specs

| NO | Name | Content |

| 1 | Air Compression | Oil-free dry compressed air, 6 bar |

| 2 | Air volume | Approx. 10 liters per second |

| 3 | Voltage | U = 24 V DC, I max = 0.15 A |

| 4 | Weight | 23KG(including gun clearing station base) |

| 5 | Program Control | Pneumatic |

| 6 | Clearance time | Approx. 4-5 seconds |

| 7 | Anti-splatter capacity | 500 ml |

| 8 | Anti-splash agent injection volume | Adjustable |

Application

Welding robot gun cleaning station

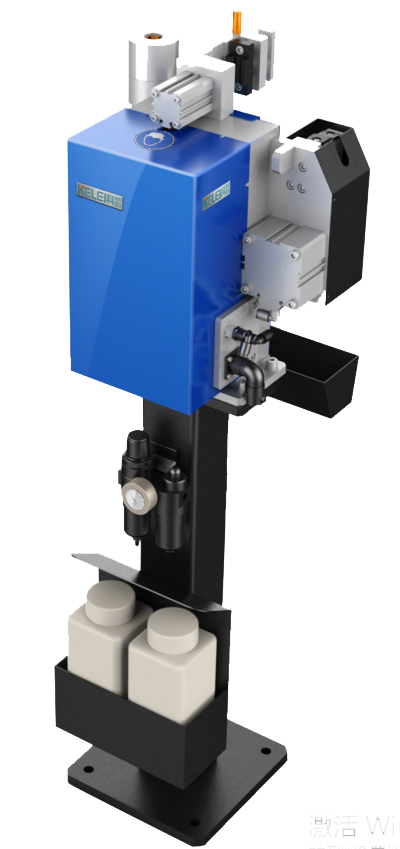

- Inject oil into a confined space, waste oil can be recycled, and does not pollute the environment.

- Unique fuel injection chamber design ensures even spraying of anti-splash fluid.

- The clamping cylinder clamping nozzle has a sensor.

- With the intelligent sensor of the motor lowering to the bottom, it ensures that the welding gun can be removed only after the gun cleaning is completed, reducing accidental gun collision accidents.

- A start signal can control the motor to rotate and rise, achieving gun-clearing action and reducing robot I/O wiring.

- With the multi-function reamer, the cleaning gun can reach the root of the contact tip seat.

Packing details

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System