Description

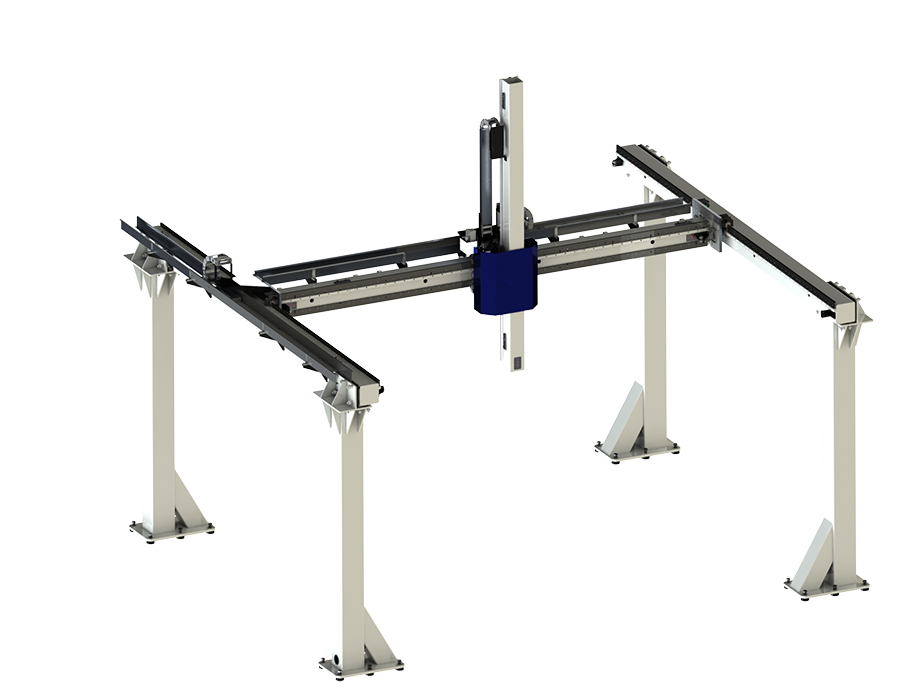

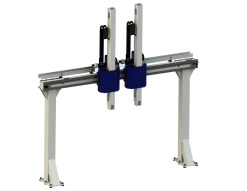

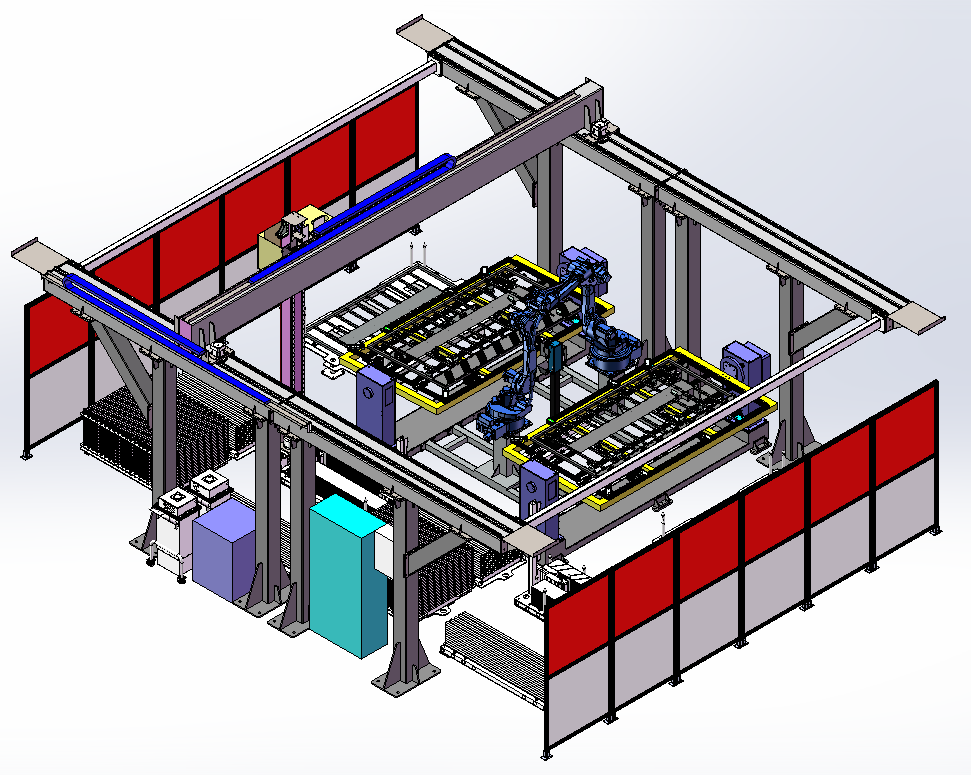

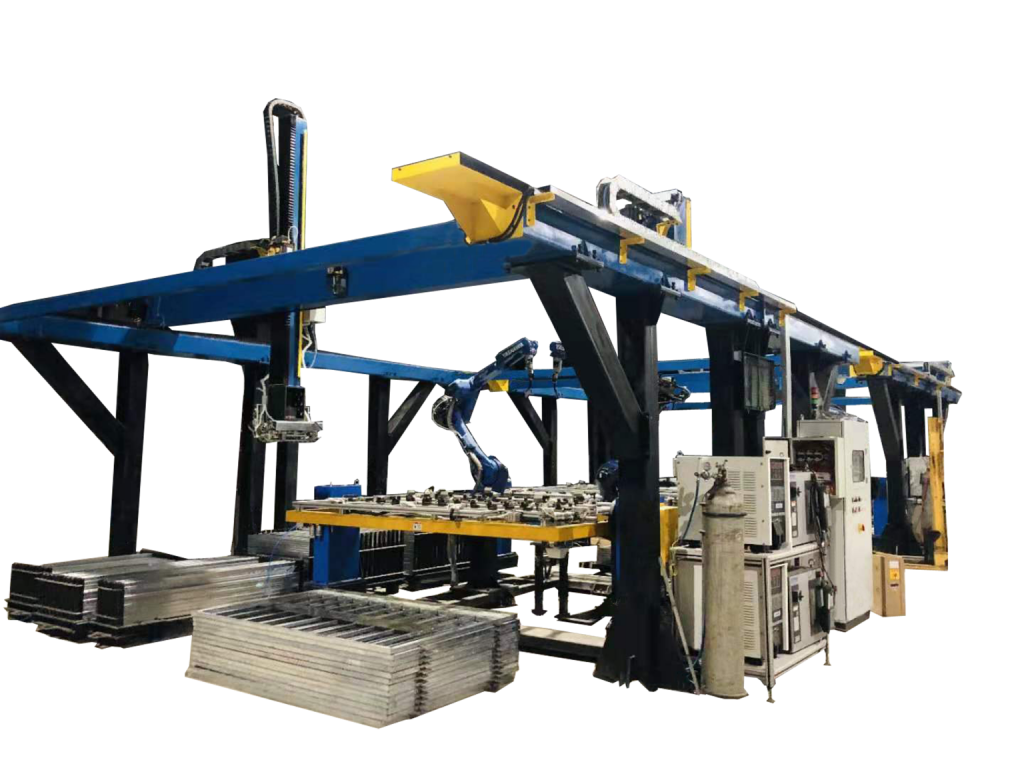

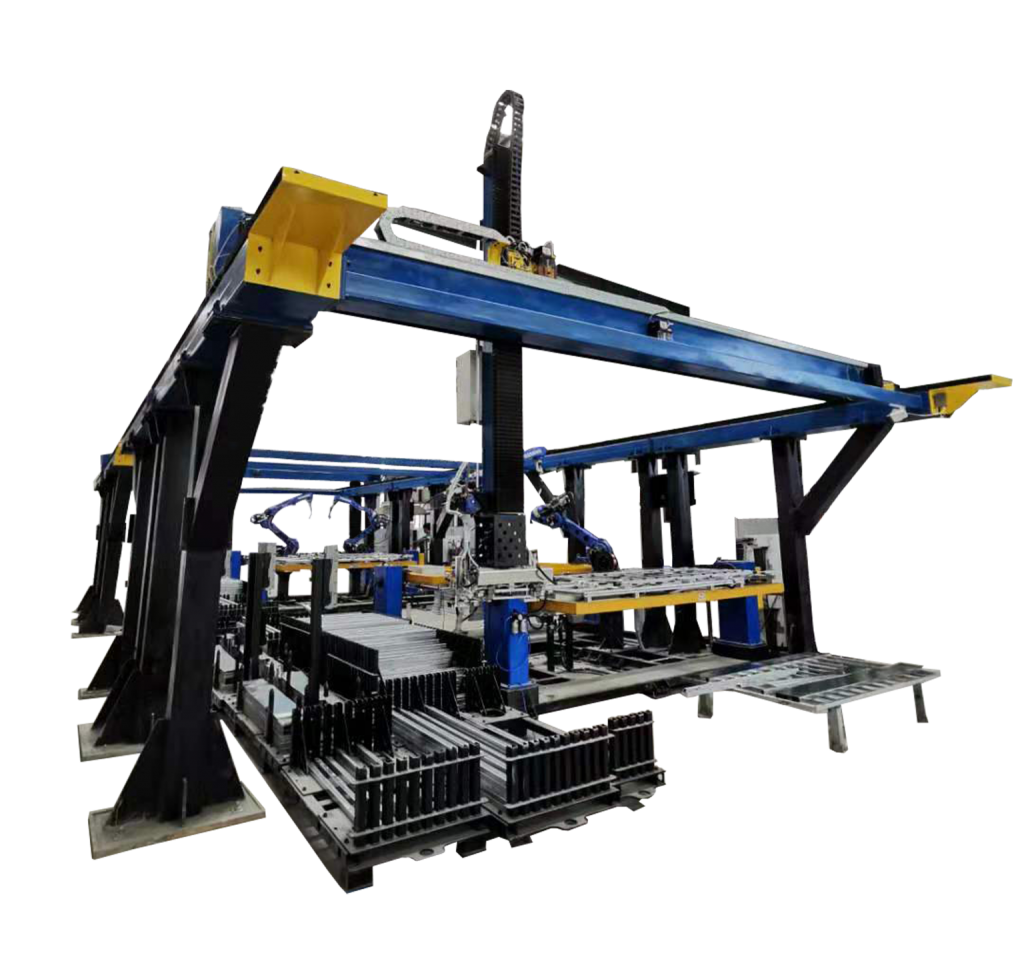

Heavy duty upright cantilever single arm truss robotics gantry system automation

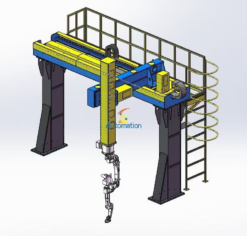

Truss Robot: It can also be called a truss manipulator, gantry robot, is a kind of linear motion unit built on a Cartesian coordinate system, generally there are XZ gantry two-axis, XYZ gantry three-axis, XYZR gantry four-axis, and other structures.

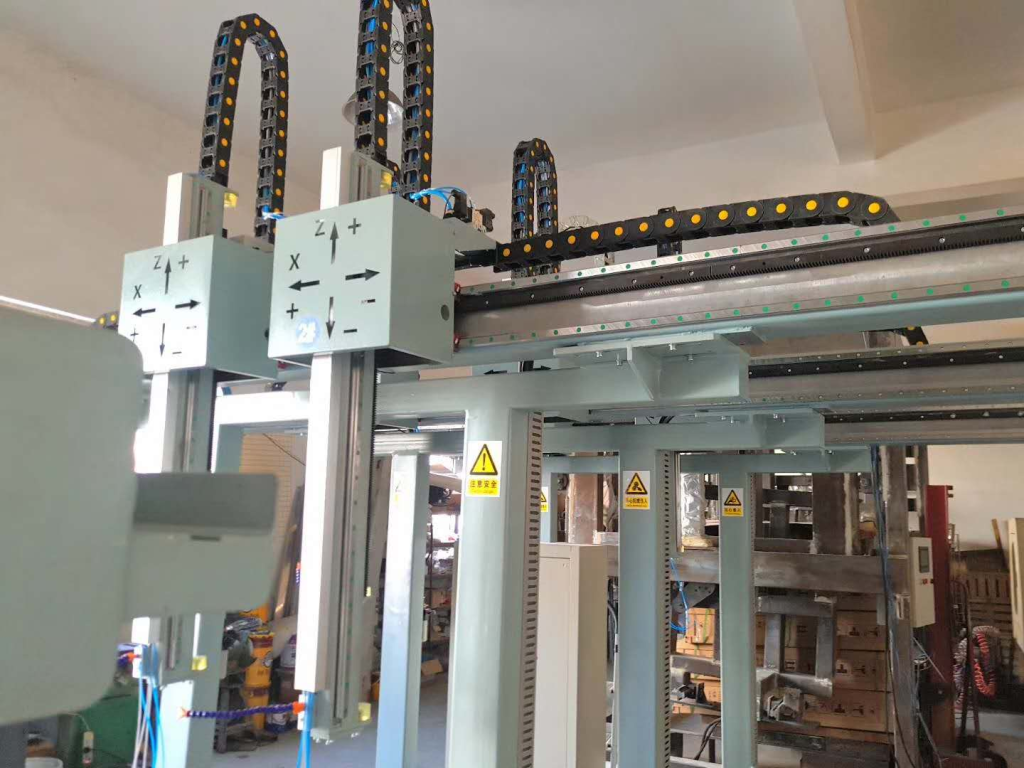

The body of the motion unit can be made of high-strength aluminum alloy or rectangular tube, linear guide, V-type guide, heavy-duty roller guide, rack and pinion, roller screw, synchronous belt, and other combinations.

As the frame of the kinematic unit body in the truss robot, its cross-section is modularly designed through finite element analysis to ensure high strength and high precision under long-term life.

Continuously optimize the structure of the motion unit and improve the selection of the guide rail, so that the truss robot in terms of reliability, low noise, load capacity, maintenance-free and other aspects, and the overall performance of the best.

Single axis (gantry system)

Advantages

- Robot 7th axis truss is a specialized product for automated production lines. The truss can be designed non-standard to meet customer needs.

- The truss is driven by a Siemens servo motor and driven by a precision planetary reducer and a high-precision rack and pinion, which has low noise, stable movement, and high repetitive positioning accuracy.

- The movement of the truss manipulator can be controlled individually or connected with on-site equipment to realize linkage.

- The effective travel range of the truss manipulator is wide, every position can be used, and the long travel can be customized.

- It can be used in handling, machine loading and unloading, welding, spraying, and other industries, with a wide range of application scenarios.

- The structure is fixed and calculated by finite element analysis, short cycle time, easy to install, low failure rate, high safety, and easy to maintain.

- The control core of the truss robot is usually realized by PLC or robot control system, the human-machine interface is easy to learn and operate.

- The human-machine interface is easy to learn and convenient to operate, and the powerful teaching program can adapt to different work requirements: handling, transplanting, loading and unloading, palletizing, and so on. The bus-type absolute servo makes the structure of the truss robot more simple, the power performance more excellent and the positioning accuracy more accurate.

- The automatic solid-state centralized lubrication system adopts automatic quantitative grease to make every transmission part, and friction part, such as linear guide, guideway, and friction part.

- Friction parts such as linear guides, heavy-duty rollers, rack and pinion, ball screws, etc. can be fully lubricated to be more efficient, energy-saving, and maintenance-free for life.

Specs

Item |

Parameters of single-arm truss |

| Z-Axis end load | 50-3000kg |

| Motor brand | Shimpo or other robotics servo motor brand |

| X max speed | 1m/s-1.5m/s |

| Acceleration | 0.5-1m/s² |

| Acceleration time | 1s |

| Curacy Repetitive positioning | ±0.1mm |

Application

- Welding application: arc welding, resistance welding, laser welding, and other welding;

- Product description: the system includes industrial robots, welding equipment, sensing system, displacement system, exhaust and dust removal system, and auxiliary equipment;

- CNC loading and unloading: machine tool industry such as plate shearing machines, bending machines, punch, machining centers, and transportation industry of heavy load product processing and assembly;

- Stacking application: palletizing and unstacking of products in the chemical industry, household appliances, food industry, military industry, and other industries;

- Spray application: automobile, digital 3C, ceramics, and furniture processing industries.

Packing details

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System