Description

Intelligent ARM Robotics Cutting-Edge ARM Robot Solutions – Revolutionize Your Automation

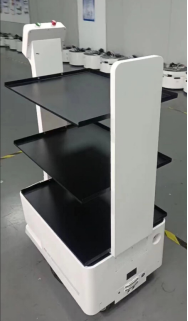

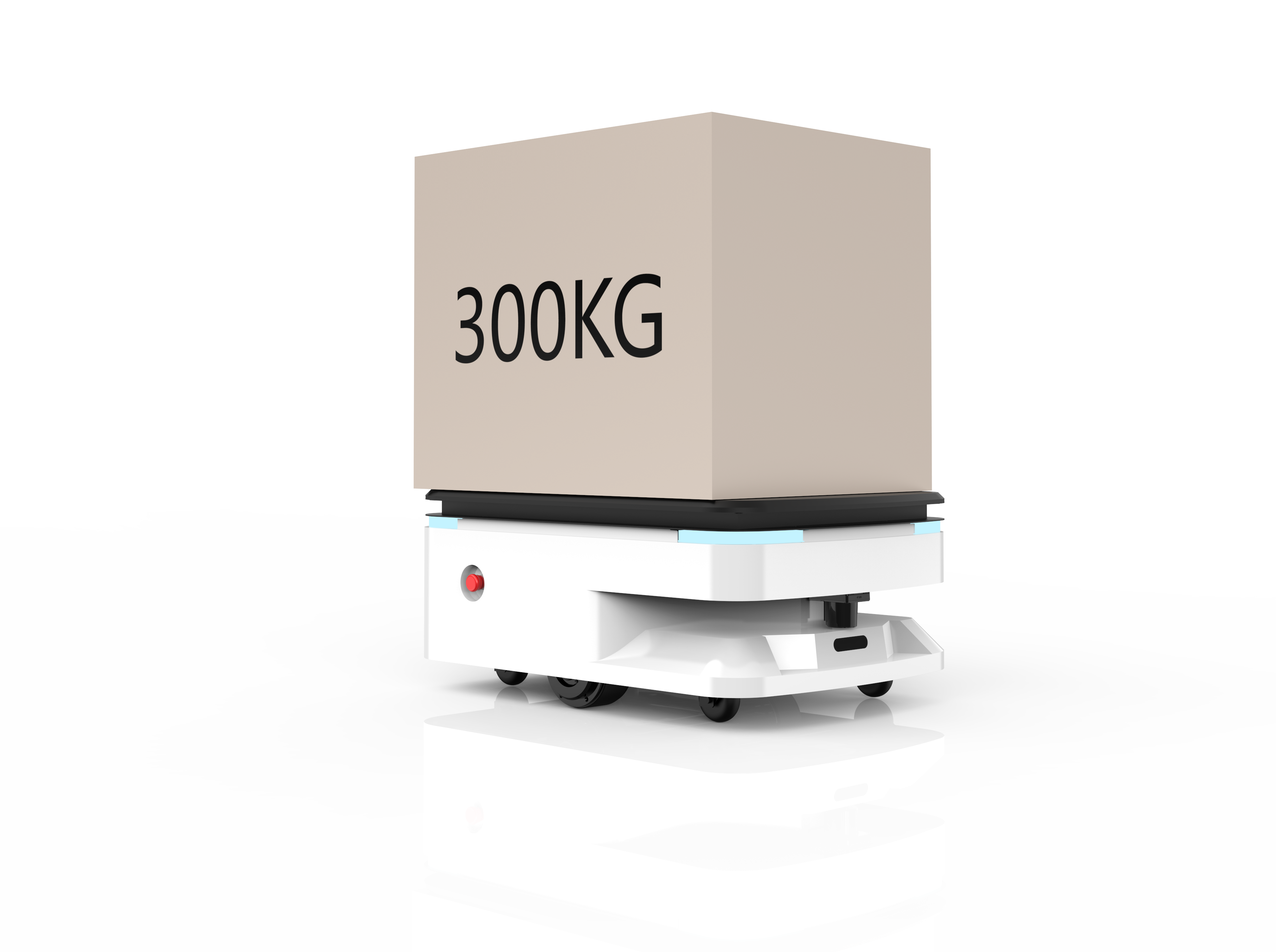

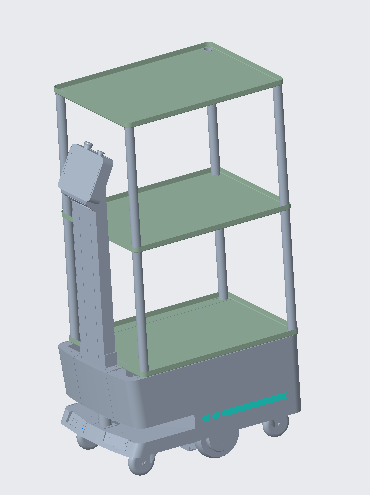

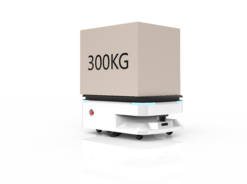

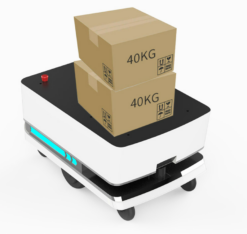

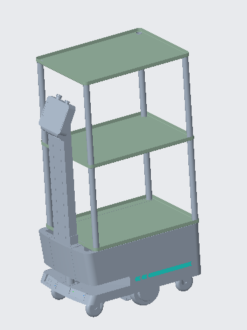

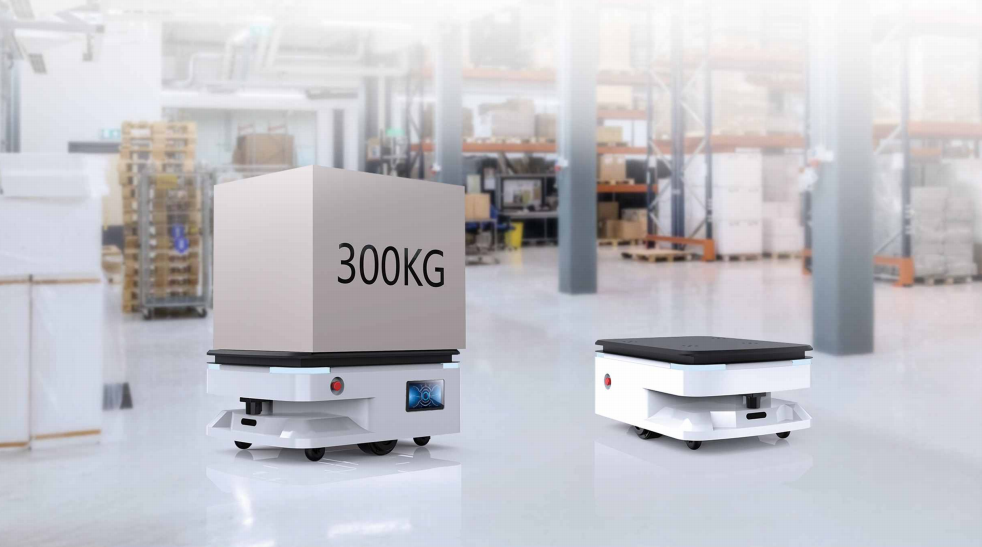

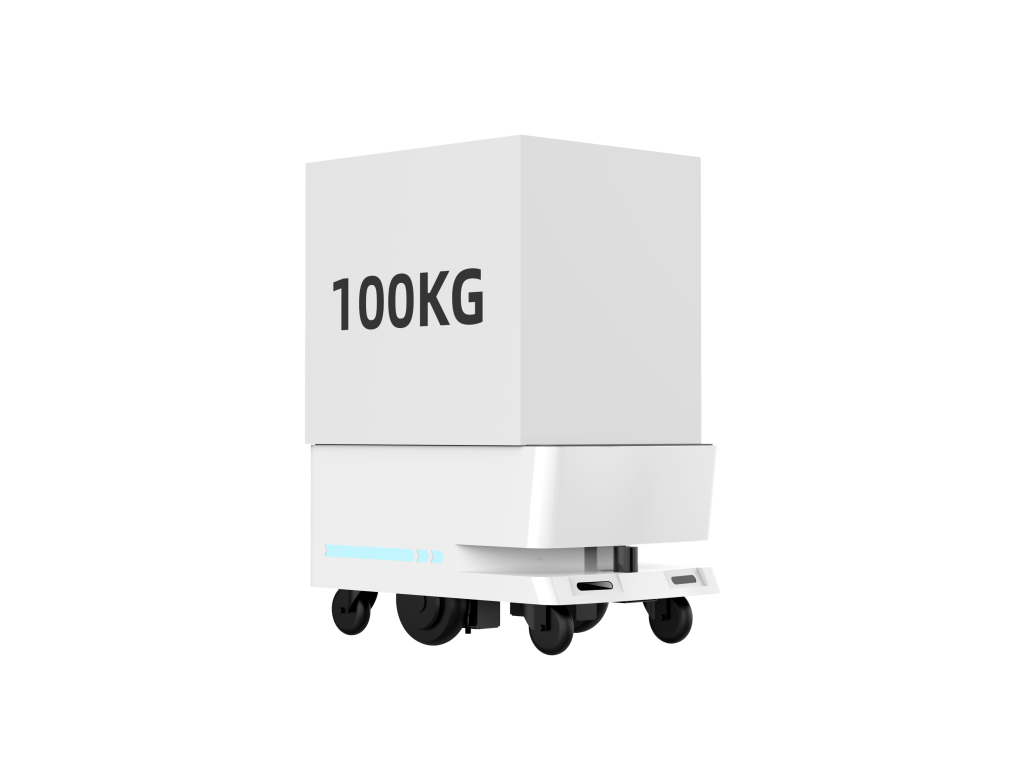

Welcome to the future of factory automation with our cutting-edge AMR robot payload100-300kg. Designed to revolutionize the way goods are transported within your industrial facility, this powerful robot combines strength, agility, and intelligence to streamline your delivery processes like never before.

What is an AMR Robot?

AMR stands for Autonomous Mobile Robot. AMRs are a type of mobile robot that can navigate and perform tasks in dynamic environments without the need for fixed infrastructure or predefined paths. They use advanced sensors, mapping, and navigation algorithms to safely navigate and transport materials or goods within a facility.

Key Features of AMR Robots:

- Autonomous navigation: AMRs can navigate complex environments and adapt to changes without the need for fixed routes or infrastructure.

- Flexible deployment: AMRs can be easily deployed and redeployed to different areas as operational needs evolve.

- Improved safety: AMRs use sensors and software to detect and avoid obstacles, ensuring safe operation around human workers.

- Increased efficiency: AMRs can optimize material transport and logistics, reducing manual effort and improving overall productivity.

Advantages

Parameter advantages:

1. Configuration of the industry’s safest lithium iron phosphate battery, will not catch fire will not explode, has stronger safety performance, and life is 4-5 times of the ternary lithium battery.

2. Configuration of automatic charging function;

3. Navigation configuration LIDAR + 3 groups of 3D cameras, chassis using Intel i5 large power industrial computer, to ensure that the navigation can be a long time stable and safe operation;

4. Support multi-machine scheduling function, FMS (Fleet management system)

5. Open robot APP source code and SDK interface, support docking MES system;

6. Load capacity of 50KG-100KG-300KG can be selected.

- AMRs can navigate dynamic environments and adapt to changing workflows without the need for fixed infrastructure.

- They can be easily deployed and redeployed to different areas of the facility as operational needs evolve.

- AMRs operate 24/7 without breaks, improving overall productivity.

- They can optimize material transport and logistics, reducing human effort and increasing throughput.

- AMRs use advanced sensors and software to navigate safely around people and obstacles, reducing the risk of collisions.

- They can handle dangerous or repetitive tasks, keeping human workers out of harm’s way.

- AMRs require less infrastructure investment compared to traditional automation solutions.

- They can reduce labor costs by automating material handling tasks.

- AMRs generate valuable data on fleet utilization, productivity, and performance.

- This data can provide insights to optimize operations and workflows.

- AMR fleets can be easily scaled up or down based on changing business needs.

- The modular nature allows for seamless integration with existing systems and workflows.

Specs

Application

AMR robots are widely used in various industries to automate material handling and transportation tasks, including:

Logistics and Warehousing:

- Order fulfillment and product movement within warehouses and distribution centers

- Inventory management and replenishment

- Last-mile delivery and urban logistics

Manufacturing:

- Automated material delivery between production lines and workstations

- Handling of heavy or bulky materials

- Streamlining of internal logistics and supply chain processes

Retail and E-commerce:

- Automated product transport and shelf replenishment in retail stores

- Order picking and fulfillment in e-commerce warehouses

- Autonomous floor cleaning and maintenance

Healthcare:

- Transporting medical supplies, medications, and patient records within hospitals

- Automating the movement of materials and equipment in pharmaceutical facilities

Food and Beverage:

- Automated movement of raw materials, ingredients, and finished products

- Streamlining of production and distribution workflows

AMR robots can be seamlessly integrated with other automation technologies, such as robotic arms (ARM robots), to create comprehensive and highly efficient automation solutions across various industries.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System