Introduction

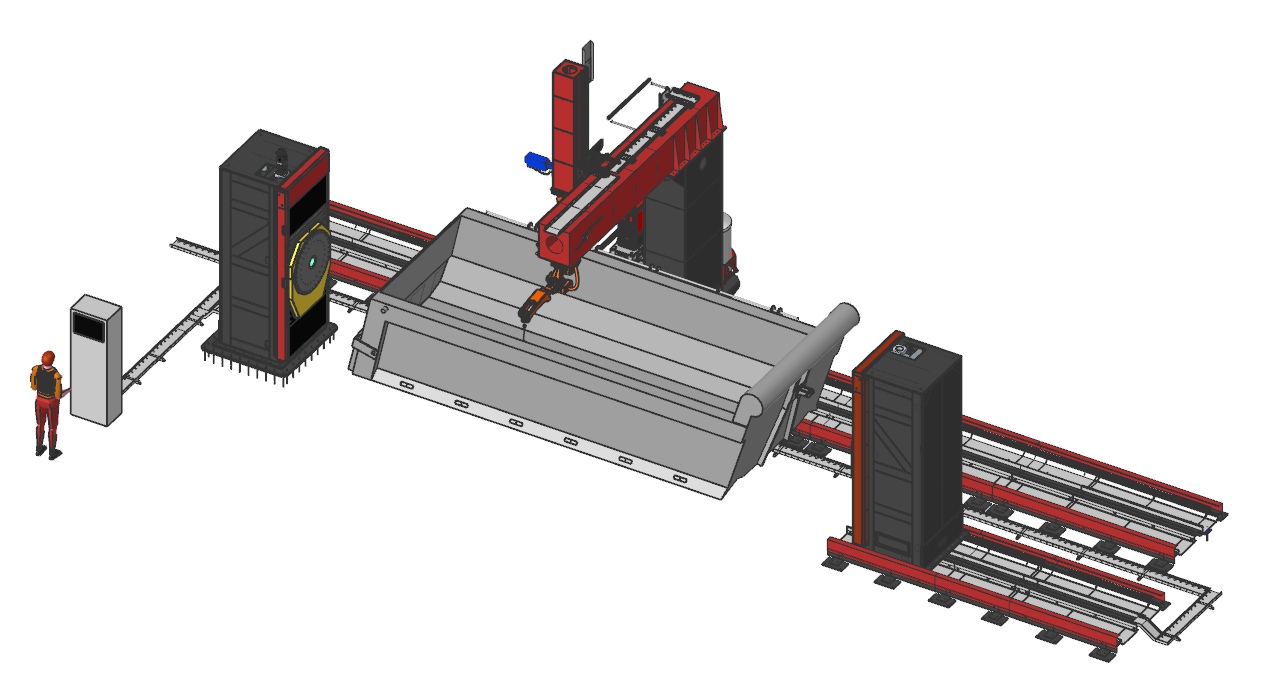

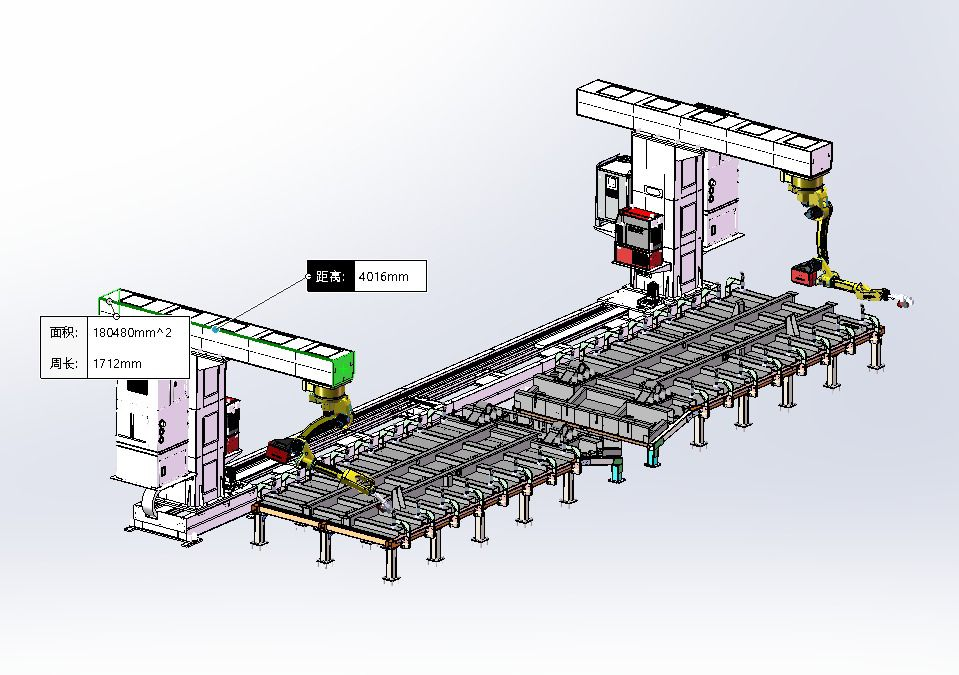

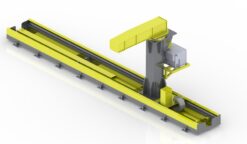

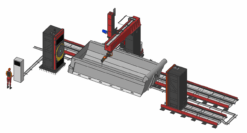

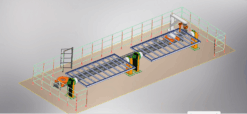

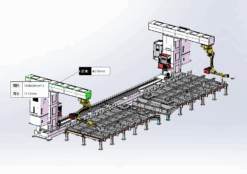

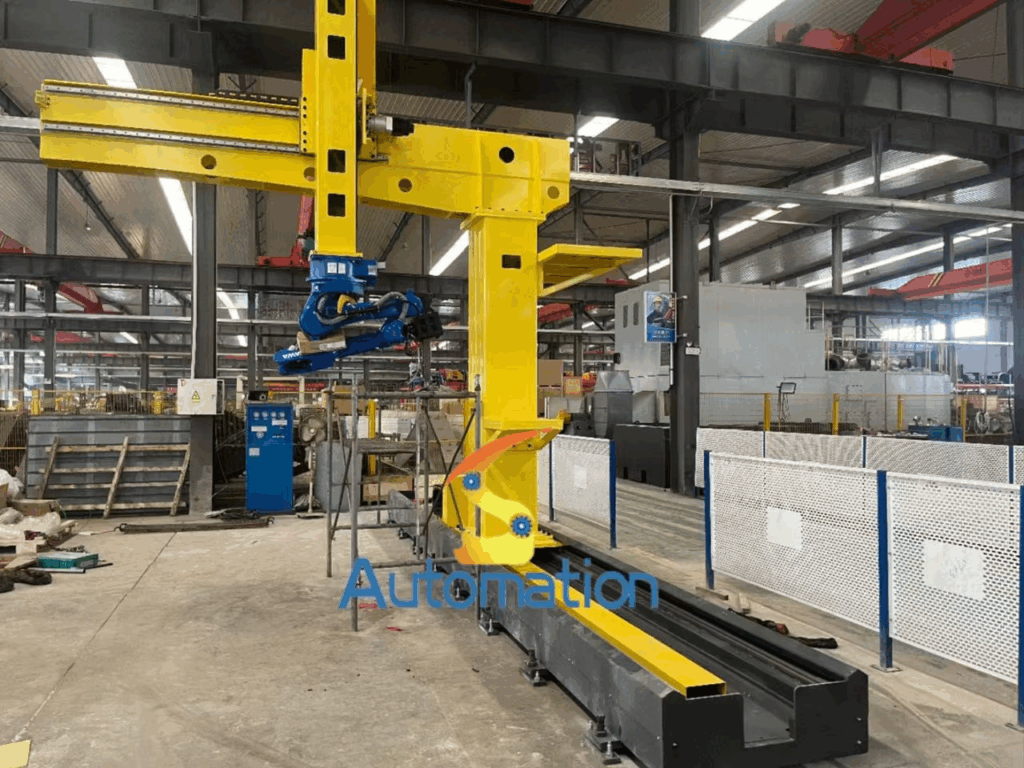

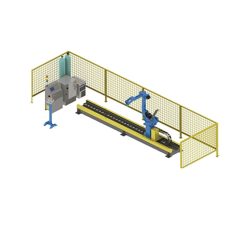

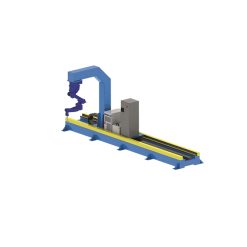

In large-scale industrial manufacturing, the reach of a stationary robot is often the primary bottleneck for productivity. The Robot Slider (Model: AUT-DW-XY-Z/D-M-XXX) is a high-performance two-axis linear rail system engineered to eliminate these boundaries. By providing a stable, high-precision overhead or floor-mounted mobile platform, it allows articulated and collaborative robots to traverse long distances—up to 30 meters—while maintaining the rigorous accuracy required for automated welding and heavy-load assembly.

Core Technical Specifications

Designed for seamless integration with major controllers like FANUC and Yaskawa, the system utilizes a servo-driven gear-and-rack mechanism for reliable continuous operation.

| Feature | Technical Data |

| Model | AUT-DW-XY-Z/D-M-XXX |

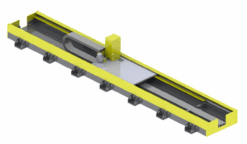

| Standard Travel (X-Axis) | 30m (Modular 4M sections) |

| Control Axes | Dual Axis (X & Y) |

| Max Cantilever Load | 500kg |

| Transmission Type | Precision Gear and Rack Drive |

| Repetitive Accuracy | X: ≤0.5mm/15m; Y: ≤0.1mm/15m |

| Movement Speed | X: 0-3000mm/min; Y: 0-6000mm/min |

| Lubrication | Automatic (46# guide rail oil) |

| Reduction Gearbox | Precision Planetary (Ratio X=20, Y=10) |

Operational Advantages for Automated Lines

1. Adaptive Workspace Expansion

Traditional fixed-base robots struggle with large-scale structures like ship hulls or crane booms. This slider’s modular 30m X-axis allows the robot to cover the entire length of a workpiece in a single pass. Because the sections can be freely combined, the system scales precisely to your facility’s footprint.

2. Rigidity Under Heavy Payloads

Handling a 500kg cantilever load requires exceptional structural integrity. The AUT-DW series uses reinforced linear guides and a sliding seat design to prevent deformation during high-torque welding tasks. This makes it a preferred solution for thick-plate welding in heavy industries where lightweight alternatives fail.

3. Precision Engineering for Weld Seam Consistency

The combination of a precision planetary reducer and a gear-rack drive ensures that movement is both smooth and highly repeatable. With positioning accuracy as tight as 0.1mm on the Y-axis, manufacturers can guarantee uniform weld quality across massive components, virtually eliminating the risk of cumulative errors over long travel distances.

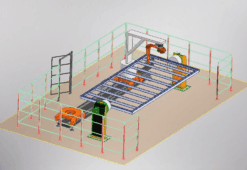

4. Streamlined Integration and Setup

Time-to-production is critical. This slider is designed to be “plug-and-play” with mainstream industrial robot controllers. Its modular nature doesn’t just offer flexibility; it reduces on-site installation and commissioning time by approximately 40% compared to custom-built, non-modular linear systems.

Primary Industrial Applications

The Robot Slider is optimized for environments where “standard” reach simply isn’t enough:

- Marine & Shipbuilding:Automated welding of deck structures and hull sections.

- Heavy Construction Machinery:Welding and assembly of excavator arms and crane booms.

- Energy & Infrastructure:Fabrication of bridge trusses, factory frames, and high-speed rail supports.

- Specialized Automotive:Frame welding for truck chassis and bus structures.

Why Partner With Us?

Beyond providing high-spec hardware, we focus on the total lifecycle of your automation investment:

- Bespoke Configuration:We tailor X/Y travel and load specs to your specific welding geometry.

- Verified Performance:Every unit undergoes rigorous dynamic testing against industrial standards before it leaves our facility.

- End-to-End Support:From initial site assessment to operator training, we ensure your team is equipped for maximum uptime.

Conclusion

Transitioning to a mobile robot setup is the most direct way to increase throughput in large-scale manufacturing. The Robot Slider provides the stability, reach, and precision needed to transform your production line into a high-efficiency operation.

Ready to expand your robot’s reach?

Contact us today for a technical consultation and a customized quote based on your facility’s requirements.

Ask for quote

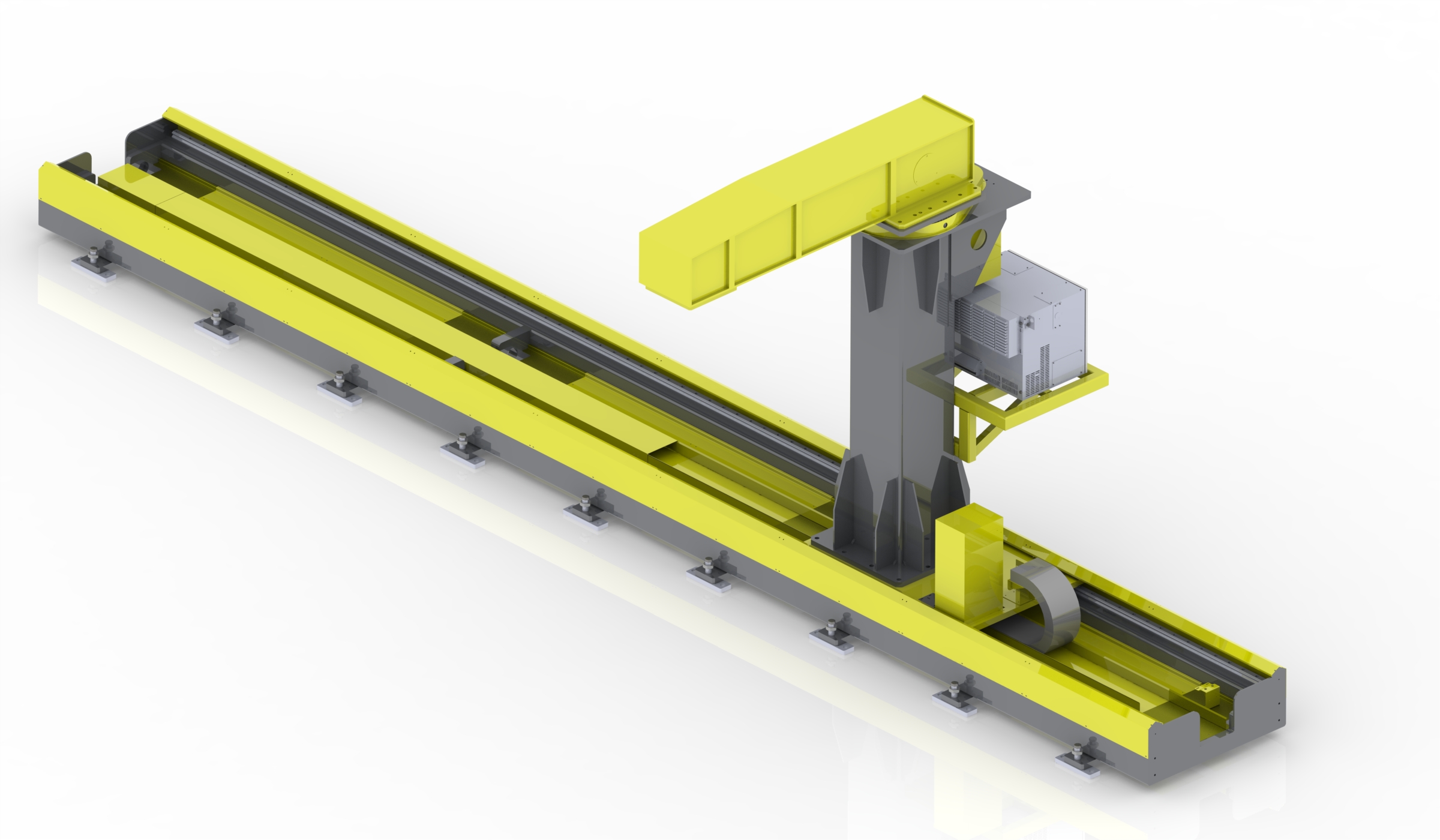

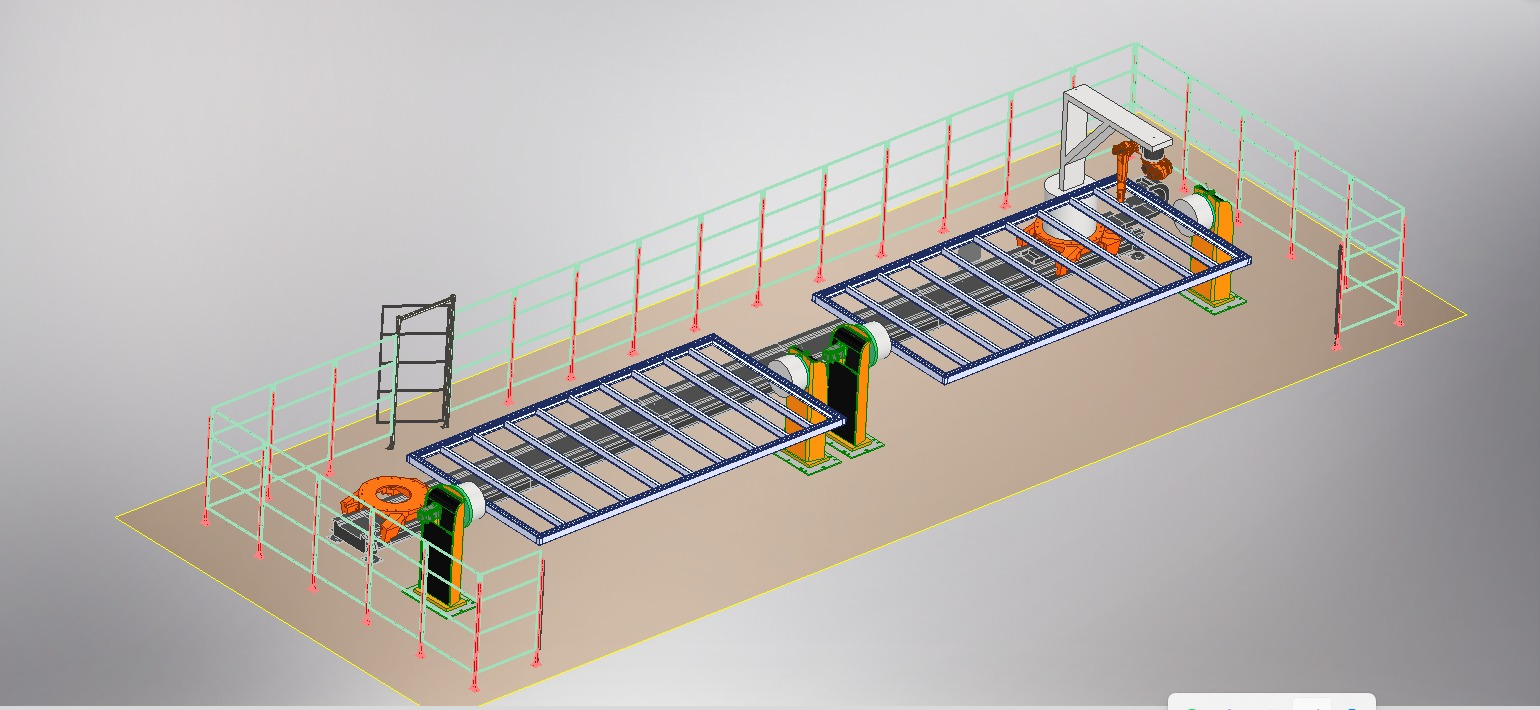

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

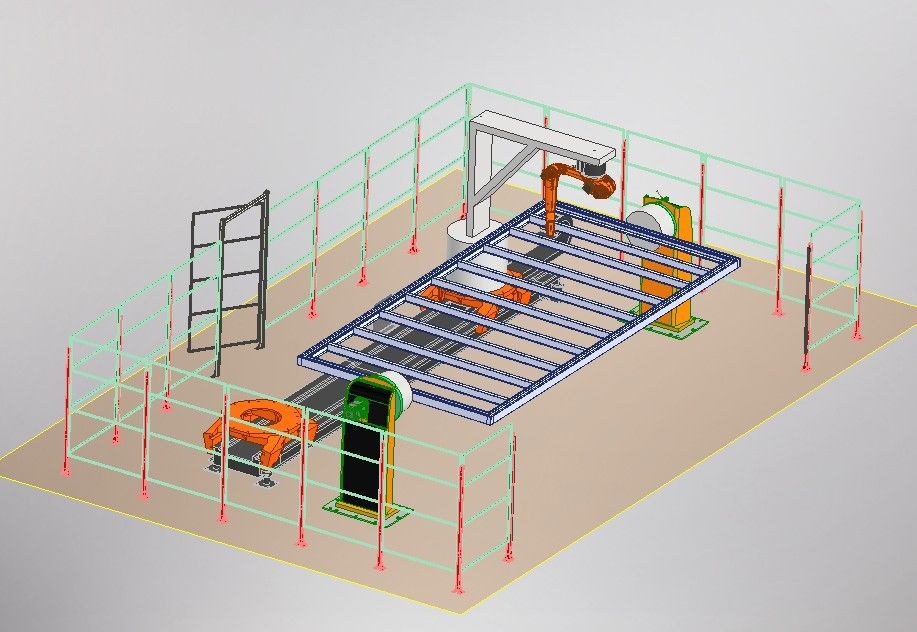

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System