Description

High-Precision Robotic Gantry System for Industrial Automation |WRS Robotics

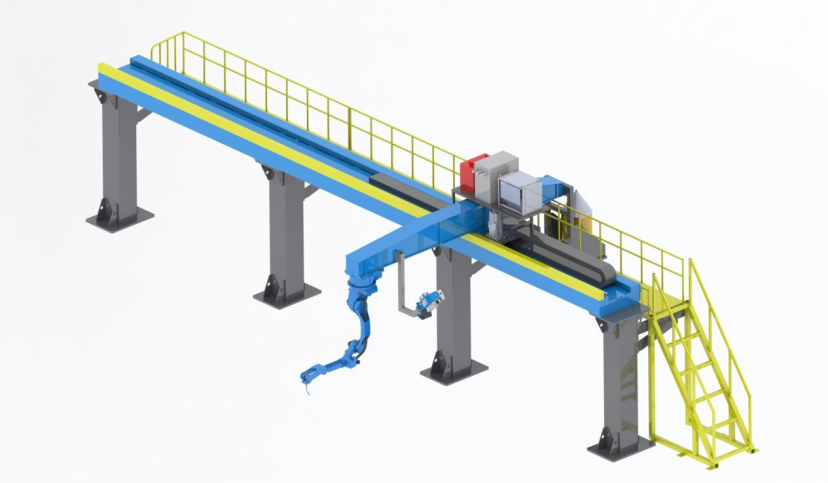

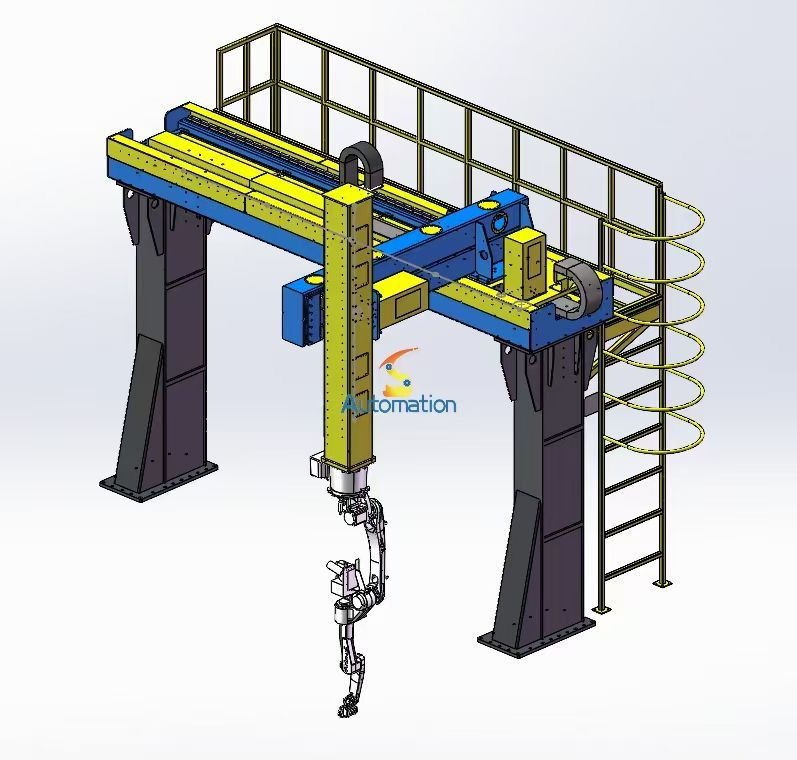

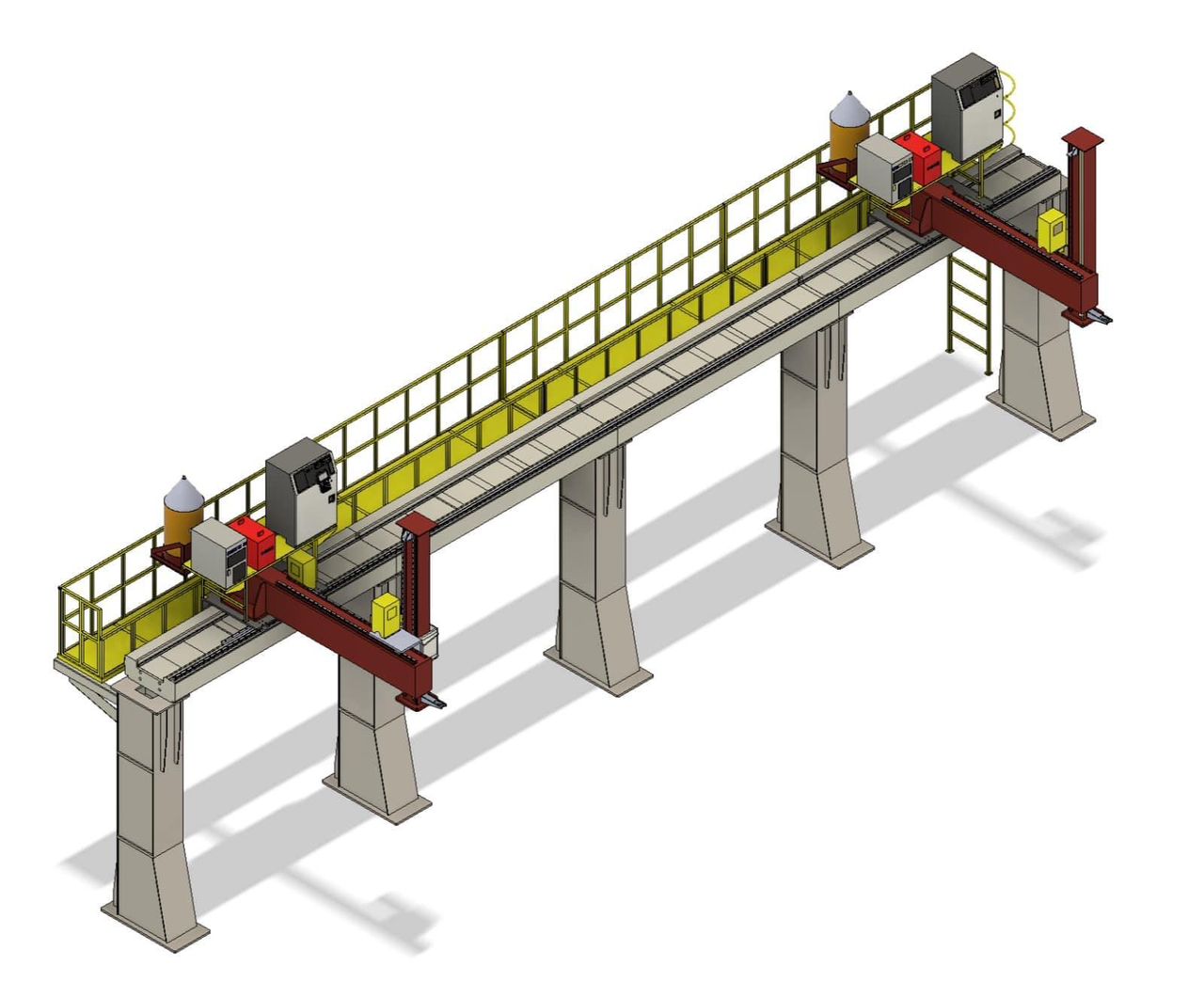

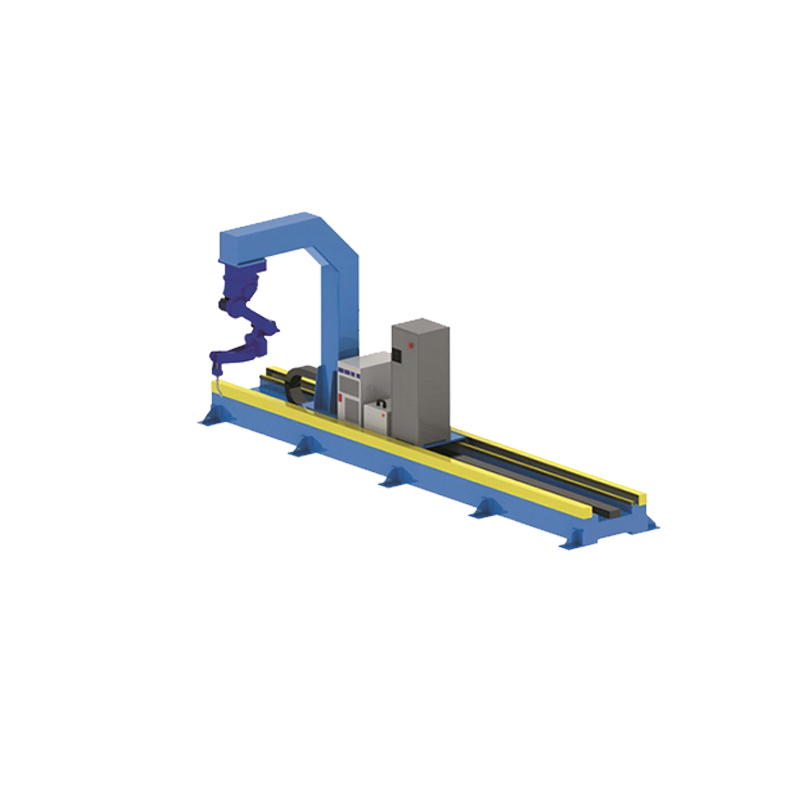

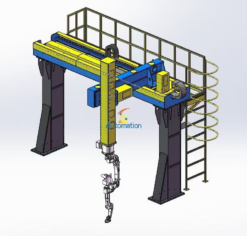

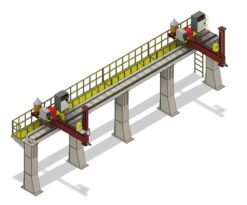

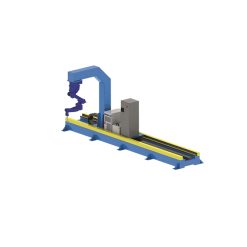

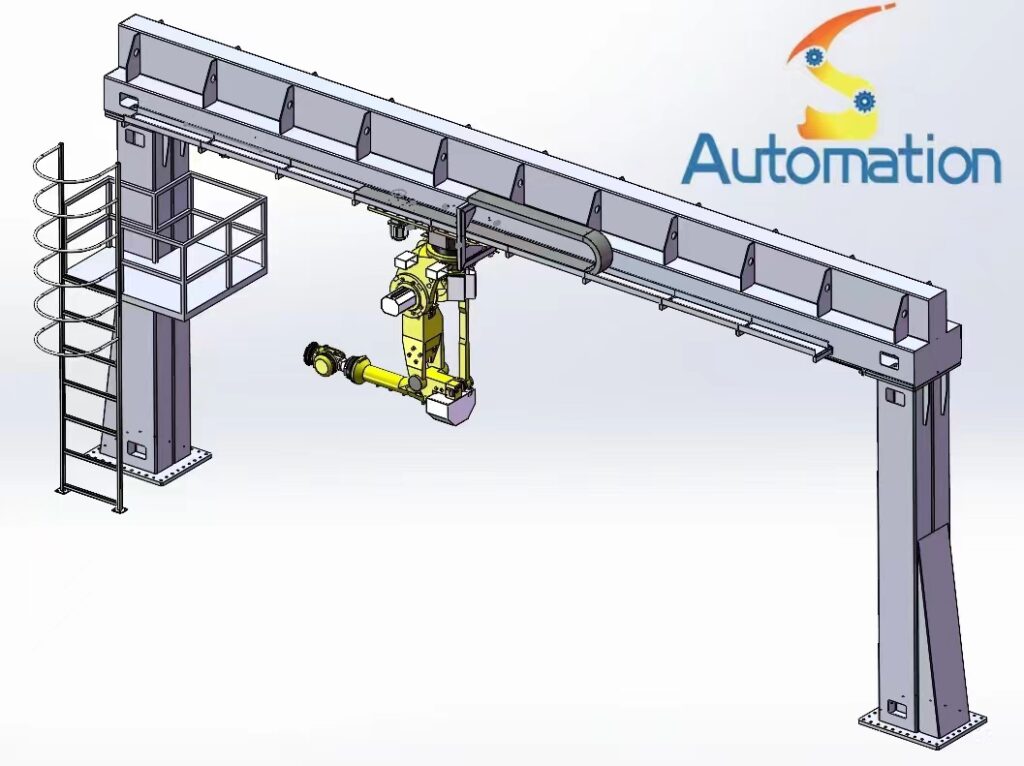

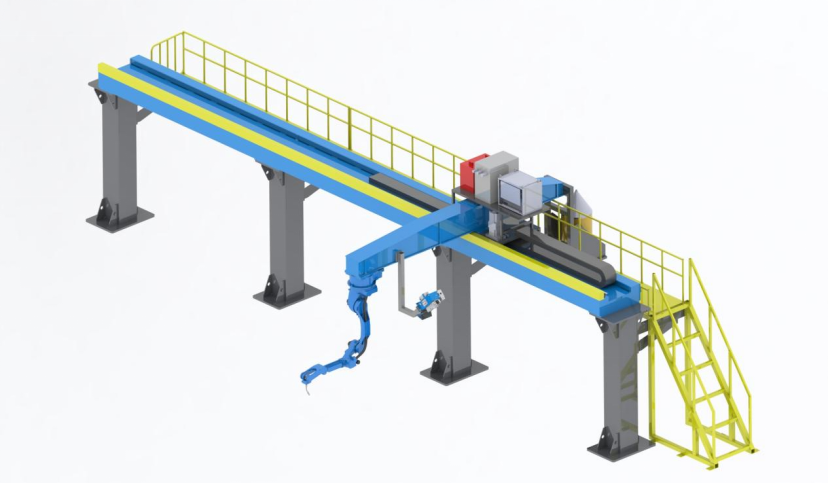

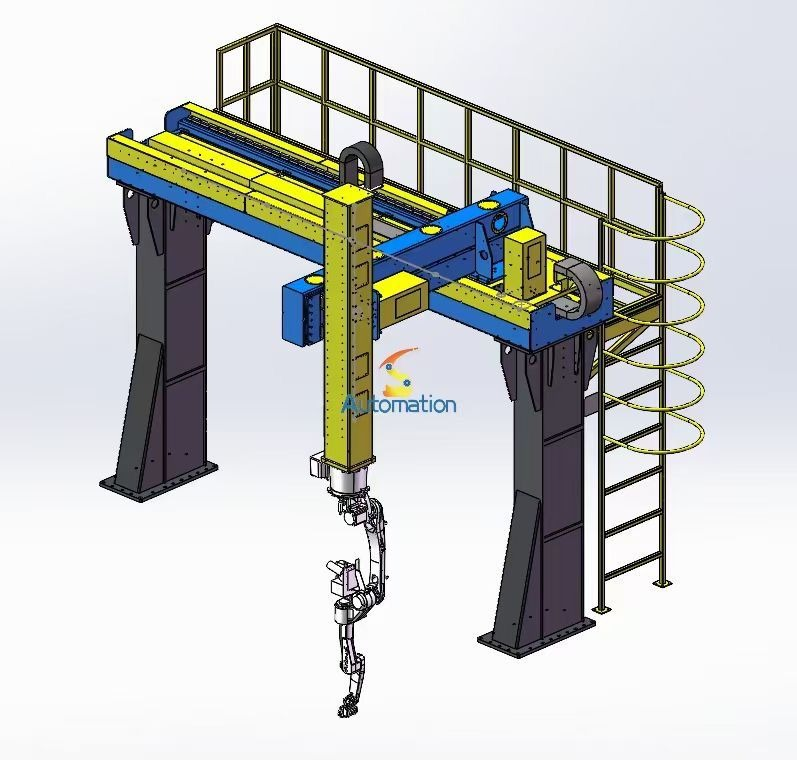

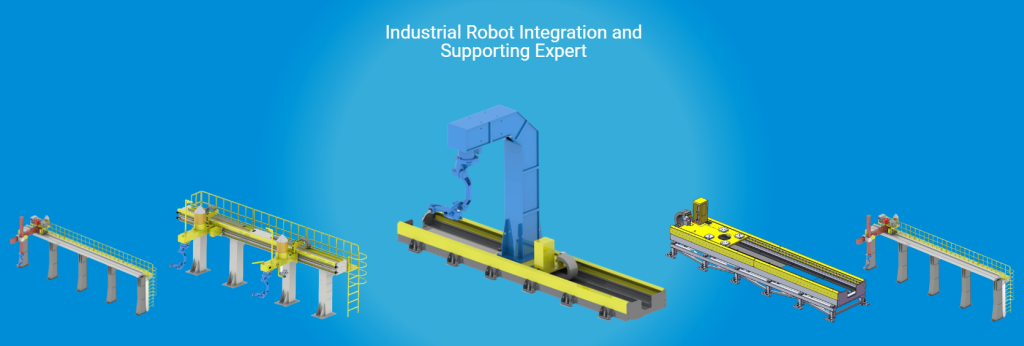

Our Robot Gantry System is a state-of-the-art automated solution designed to enhance production efficiency, precision, and flexibility in industrial settings. This robust and highly scalable system integrates seamlessly with your existing robotic arms, providing a stable platform for efficient material handling, welding, assembly, and packaging operations. With the ability to move along multiple axes, the Robot Gantry System is ideal for large-scale applications that require accuracy, speed, and minimal downtime.

Features(Technical Highlights):

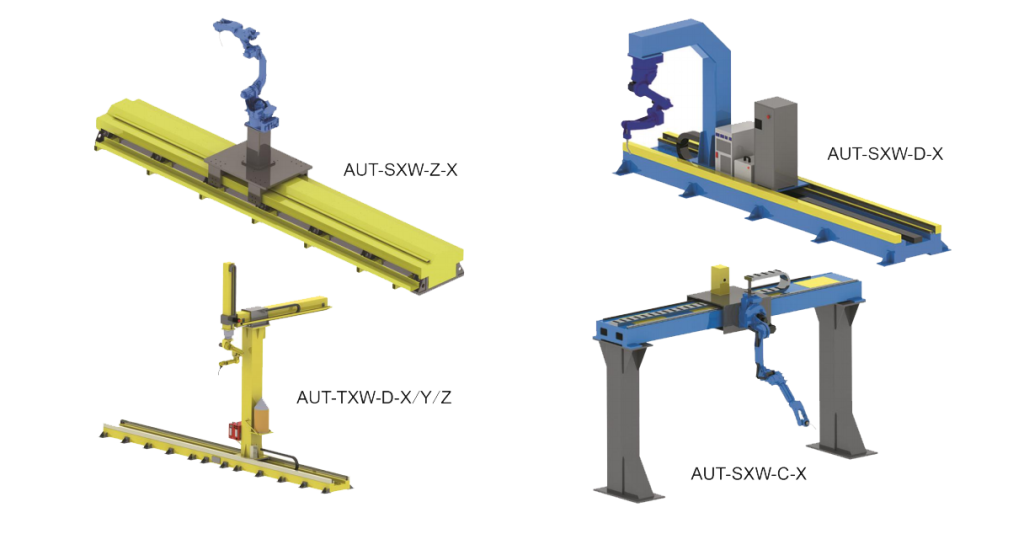

- Multi-Axis Motion Control:

The gantry system features advanced multi-axis control, offering full freedom of movement in the X, Y, and Z directions, ensuring versatility across various tasks, from material handling to welding. - Heavy-Duty Capacity:

Designed for both light and heavy-duty applications, this robot gantry system can support a wide range of payloads, ensuring it can handle larger workpieces or equipment with ease. - Flexible Configuration:

Easily adjustable and configurable to suit the specific needs of your production line. The system can accommodate a variety of robot arms and tools, offering unparalleled flexibility in different manufacturing environments. - High-Speed and Precision Movement:

Equipped with cutting-edge motion control technology, the system delivers high-speed operation without compromising on precision. This ensures faster cycle times and consistently high-quality results. - Durable Construction:

Built with heavy-duty materials, the robot gantry system is designed to withstand the demands of 24/7 industrial environments, ensuring long-term reliability and minimal maintenance. - Intuitive Interface:

The user-friendly interface simplifies operation and programming, making it easier for operators to manage and integrate the gantry system into their existing production processes. - Heavy-Duty Performance: Supports payloads up to [X] kg for demanding industrial applications.

- Modular Design: Easily customizable for CNC machining, welding, material handling, or 3D printing.

- Seamless Integration: Compatible with ABB, KUKA, FANUC, and other industrial robots.

- Smart Control: IoT-enabled for real-time monitoring and adaptive motion planning.

Advantages

- Increased Production Efficiency:

With its ability to automate complex tasks, the robot gantry system reduces manual intervention, cutting cycle times and improving throughput, which directly leads to increased productivity. - Versatile for Multiple Applications:

Perfect for industries such as automotive, aerospace, electronics, and packaging, the gantry system can be used for a wide range of applications, including assembly, welding, material handling, and more. - Space-Saving Design:

The gantry system’s design allows for maximum use of available workspace, with the ability to reach across larger areas while requiring less floor space than traditional automation systems. - Scalable for Future Growth:

The modular nature of the robot gantry system allows for easy expansion. As your business grows, you can add additional modules or integrate new robots to meet increasing production demands. - Enhanced Safety:

By automating potentially hazardous tasks, the gantry system reduces the risk of accidents in the workplace, ensuring a safer working environment for operators. - Cut Labor Costs: Eliminate manual errors and reduce reliance on skilled labor.

- Future-Proof: Scalable architecture adapts to evolving production needs.

- Low Maintenance: Durable construction with corrosion-resistant materials for harsh environments.

Specs

SW-X-Z-L robot guide rail

| No. | Item | AUT-TW-XYZ-D-L | Remarks |

| 1 | Application | Welding | |

| 2 | Number of axes | 3 Axis | |

| 3 |

Installation method

|

Ground installation

|

|

| 4 | Transmission mode

|

gear rack drive

|

|

| 5 | Guide mode

|

linear guide and slide

|

|

| 6 | Lubrication method | Automatic lubrication | |

| 7 | Gearbox | Shimpo Precision planetary reducer | |

| 8 | Reduction ratio | X axis: i=20,

Y axis: i=20 Z axis: i=50

|

|

| 9 | Acceleration | X≤0.5m/s(t>1S)

Y :≤0.5m/s'(t>1S) Z:≤0.2m/s'(t>1S) |

|

| 10 | Repeat positioning accuracy |

±0.15m

|

|

| 11 | Movement Speed | X :0-30000mm/min

Y:0-30000mm/min Z:0-10000mm/min |

|

| 12 | Effective travel length

|

X=5000mm

Y =2000mm Z =2500mm

|

|

| 13 |

Effective installation size (L*W*H)

|

400mm×400mm | |

| 14 | Cantilever column payload | payload≤500kg | |

| 15 | Lubricating oil | 46# guide rail oil | |

| 16 | Equipment net weight | Around 7200kg |

Application

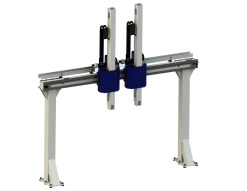

Modular Robotic Gantry Positioning System – Heavy-Duty Load Handling

1. Material Handling and Palletizing

- Application: Move heavy loads, stack pallets, or transport materials across production lines.

- Benefits: Reduces manual labor, minimizes errors, and increases throughput.

- Industries: Warehousing, logistics, and manufacturing.

2. CNC Machining and Milling

- Application: Precision cutting, drilling, and milling of metals, plastics, and composites.

- Benefits: Delivers micron-level accuracy and repeatability for complex parts.

- Industries: Automotive, aerospace, and tooling.

3. Welding and Fabrication

- Application: Automated welding for large or heavy components, such as vehicle frames or structural beams.

- Benefits: Ensures consistent weld quality and reduces operator exposure to hazardous environments.

- Industries: Automotive, shipbuilding, and construction.

4. Assembly and Inspection

- Application: Assemble components or perform quality checks using integrated vision systems.

- Benefits: Improves assembly speed and ensures defect-free production.

- Industries: Electronics, consumer goods, and medical devices.

5. 3D Printing and Additive Manufacturing

- Application: Large-scale 3D printing of prototypes, molds, or end-use parts.

- Benefits: Enables precise layer-by-layer fabrication for complex geometries.

- Industries: Aerospace, architecture, and prototyping.

6. Painting and Coating

- Application: Uniform application of paint, coatings, or adhesives on large surfaces.

- Benefits: Eliminates overspray, reduces waste, and ensures consistent finish quality.

- Industries: Automotive, furniture, and industrial equipment.

7. Laser Cutting and Engraving

- Application: High-precision laser cutting or engraving of metals, plastics, and textiles.

- Benefits: Delivers clean, burr-free edges and intricate designs.

- Industries: Jewelry, signage, and metal fabrication.

8. Packaging and Sorting

- Application: Automate packaging, labeling, and sorting of products.

- Benefits: Increases efficiency and reduces downtime in high-volume production.

- Industries: Food and beverage, pharmaceuticals, and e-commerce.

9. Research and Development

- Application: Prototyping, testing, and simulation of new processes or products.

- Benefits: Provides a flexible platform for innovation and experimentation.

- Industries: Universities, R&D labs, and tech startups.

10. Heavy-Duty Manufacturing

- Application: Handling and processing of oversized or heavy components, such as wind turbine blades or ship hulls.

- Benefits: Enhances safety and precision in handling massive loads.

- Industries: Energy, shipbuilding, and heavy machinery.

Packing details

Ready to take your manufacturing processes to the next level?

Contact us today to learn how our Robot Gantry System can optimize your production line. Our team of experts is here to provide tailored solutions to meet your unique business needs. Don’t miss out on this opportunity to increase efficiency, reduce costs, and improve your bottom line.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System