Description

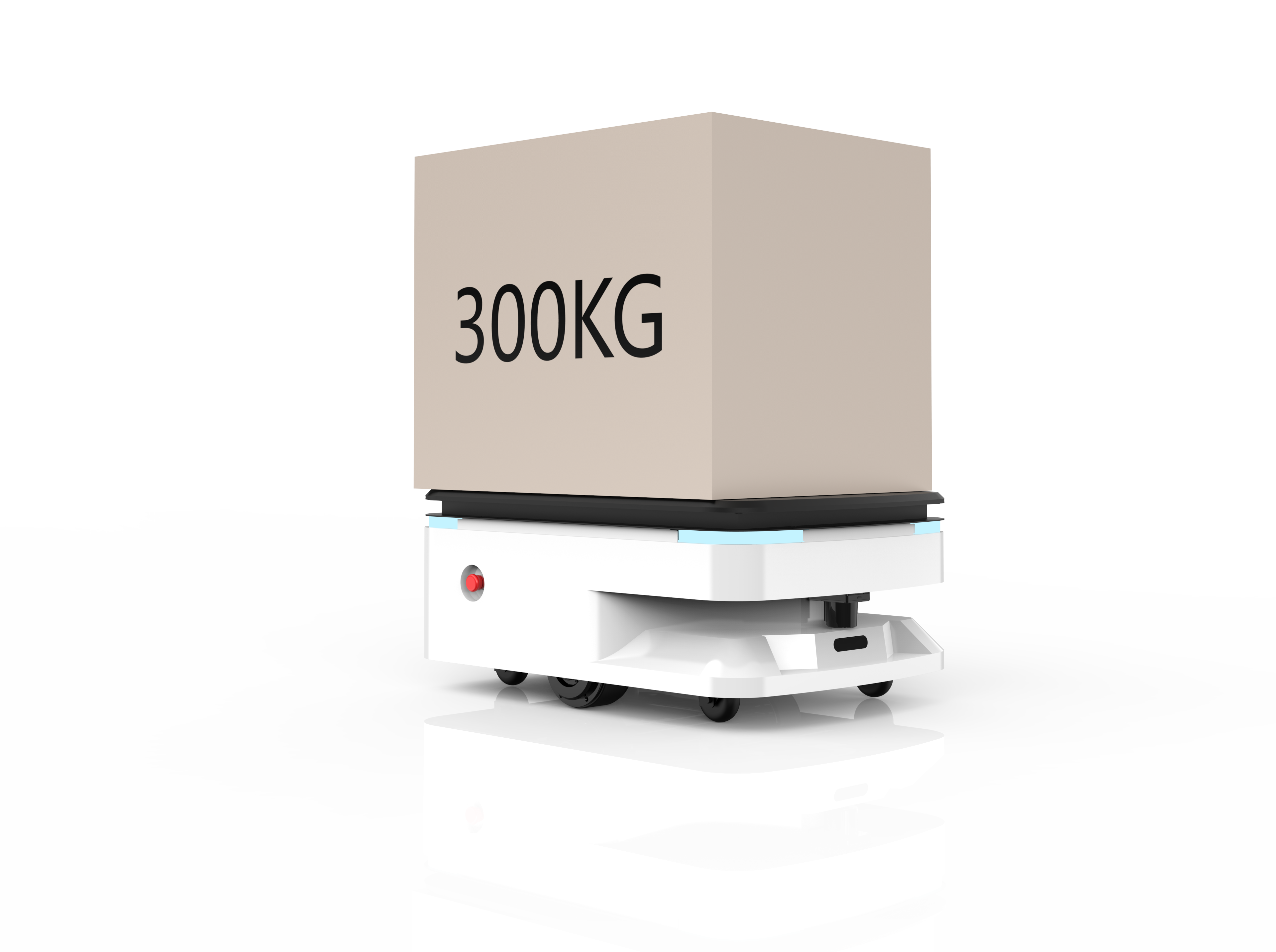

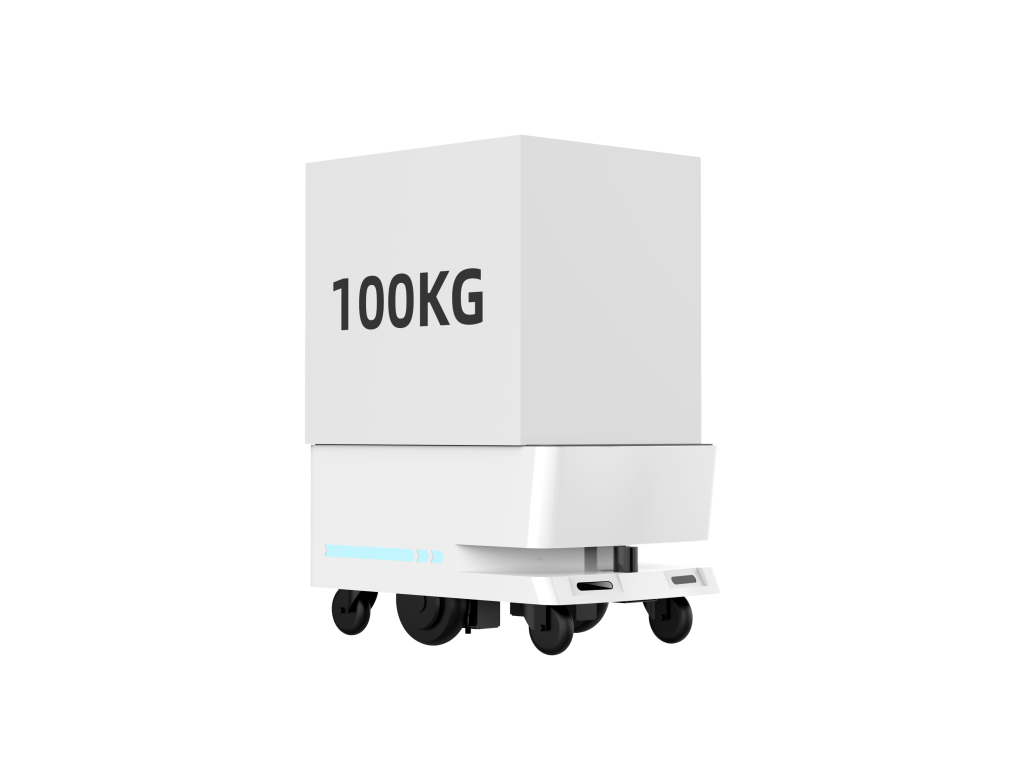

Factory delivery robot 100-300kg payload capacity robotic transport system Intelligent navigation upgrade Industrial Logistics automation

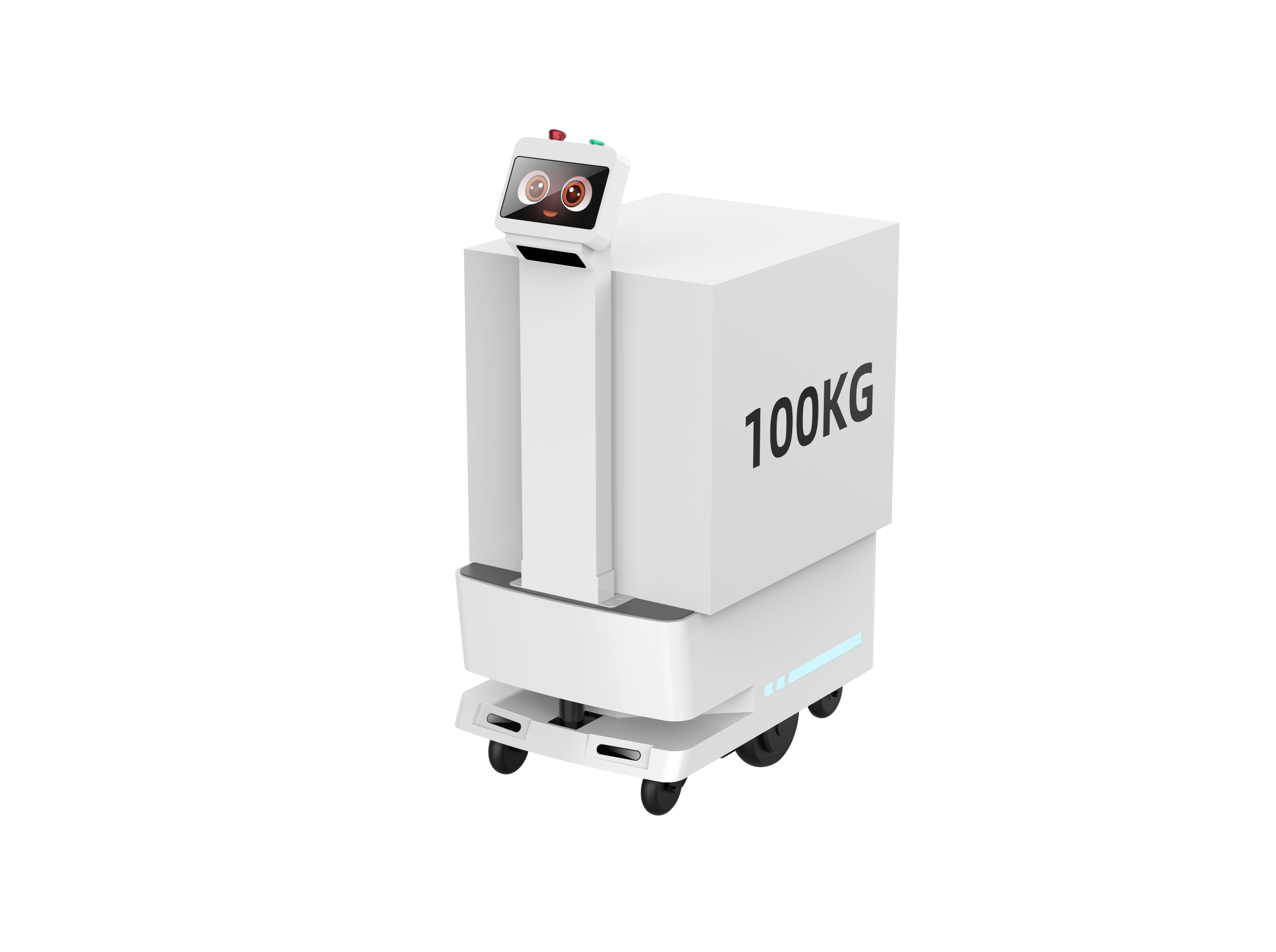

Welcome to the future of factory automation with our cutting-edge Factory Delivery Robot 100kg. Designed to revolutionize the way goods are transported within your industrial facility, this powerful robot combines strength, agility, and intelligence to streamline your delivery processes like never before.

With a maximum payload capacity of 100kg, our Factory Delivery Robot is capable of handling heavy loads with ease, eliminating the need for manual lifting and reducing the risk of workplace injuries. Whether you need to transport raw materials, finished products, or equipment across your factory floor, this robot is up to the task.

Featuring advanced navigation and obstacle detection systems, our Factory Delivery Robot ensures safe and efficient maneuverability through even the busiest and most challenging environments. Its intelligent mapping capabilities allow it to navigate complex pathways, avoiding obstacles and optimizing its routes for maximum efficiency. Say goodbye to bottlenecks and delays caused by manual transportation methods.

But that’s not all. Our Factory Delivery Robot is equipped with state-of-the-art connectivity features, allowing it to seamlessly integrate with your existing factory automation systems. This means you can effortlessly coordinate and synchronize the robot’s movements with your production schedule, optimizing workflow and minimizing downtime.

By implementing our Factory Delivery Robot 100kg, you can expect a significant boost in productivity and cost savings. With faster and more reliable transportation of goods, your production cycles will become more efficient, allowing you to meet deadlines and customer demands with ease. The reduction in manual labor will also free up your workforce to focus on more value-added tasks, driving overall operational excellence.

Experience the future of factory logistics with our Factory Delivery Robot 100kg. Embrace automation, enhance productivity, and stay ahead of the competition. Contact us today to learn more about how this innovative robot can transform your factory delivery processes.

Advantages

Parameter advantages:

1. Configuration of the industry’s safest lithium iron phosphate battery, will not catch fire will not explode, has stronger safety performance, and life is 4-5 times of the ternary lithium battery.

2. Configuration of automatic charging function;

3. Navigation configuration LIDAR + 3 groups of 3D cameras, chassis using Intel i5 large power industrial computer, to ensure that the navigation can be a long time stable and safe operation;

4. Support multi-machine scheduling function, FMS (Fleet management system)

5. Open robot APP source code and SDK interface, support docking MES system;

6. Load capacity of 50KG-100KG-300KG can be selected.

Specs

- Model: DBOT11G0

- Length and width size: 700*470mm

- Load capacity: 100KG,200KG,300KG

- Mobility: Horizontal can walk in any direction.

- Positioning navigation: LIDAR indoor navigation and obstacle avoidance.

- Control board motherboard: Cortex-A7. Android 5.1; main chip: RK3128

- Navigation motherboard: i5 LINUX industrial computer motherboard

- Auxiliary obstacle avoidance: equipped with 2 sets of 3D cameras to provide visual assistance to avoid obstacles;

- Charger: a 43.2V 5A charger.

- Charging pile: one automatic charging pile;

- Wheels: 4 universal wheels, 2 6.5-inch active wheels;

- Display: 7-inch display optional; capacitive full touch panel; resolution 1024*600;

- Load capacity: 100KG

- Shell material: ABS board

- Battery capacity: 38.4V25AH, total capacity 960W;

- Battery material: lithium iron phosphate battery;

- Battery life: the cycle life of a single battery full/discharged reaches more than 2000 times;

- Warranty: 1 year

- After-sales: remote assistance to troubleshoot problems, most of the problems can be seen backstage, there are problems that will be free to provide accessories, accessories are modular, electrical maintenance capabilities can be completed robot repair, will also provide replacement parts video

Application

Factory delivery robots have a wide range of application scenarios and can be utilized across various industries. Here are some common application scenarios and industries where factory delivery robots excel:

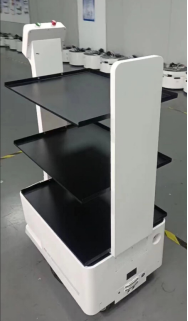

Manufacturing Facilities: Factory delivery robots are ideal for transporting raw materials, components, and finished products within manufacturing plants. They can efficiently move goods between different production stations, assembly lines, and storage areas, enhancing workflow and reducing manual labor.

Warehousing and Distribution Centers: In large-scale warehouses and distribution centers, factory delivery robots can navigate through aisles, picking up and delivering items to specified locations. They optimize order fulfillment processes, minimize errors, and increase overall operational efficiency.

Automotive Industry: Factory delivery robots are used in automotive manufacturing plants to transport heavy components, such as engines or chassis, across different assembly lines. They improve logistics within the facility, ensuring just-in-time delivery of parts and reducing production bottlenecks.

E-commerce and Retail: In e-commerce fulfillment centers and retail warehouses, factory delivery robots assist in inventory management and order fulfillment. They can efficiently pick and transport products from storage shelves to packing stations, accelerating order processing and improving customer satisfaction.

Healthcare: Factory delivery robots are employed in hospitals and healthcare facilities to transport medical supplies, equipment, and medication between different departments. They ensure timely delivery and help healthcare professionals focus more on patient care.

Food and Beverage Industry: In food processing plants, factory delivery robots can safely transport ingredients, packaging materials, and finished products across different production stages. They maintain hygiene standards and optimize the movement of goods, reducing manual handling and potential contamination risks.

Logistics and Fulfillment: Factory delivery robots are utilized in logistics and fulfillment centers to streamline the movement of packages and goods. They navigate through complex warehouse layouts, load and unload items, and contribute to efficient order fulfillment and shipping operations.

Electronics Manufacturing: Within electronics manufacturing facilities, factory delivery robots help transport delicate electronic components, circuit boards, and equipment between different assembly stations. They minimize the risk of damage and improve production efficiency.

These are just a few examples of the diverse application scenarios and industries where factory delivery robots find their utility. As automation continues to advance, these robots are expected to play an increasingly significant role in optimizing industrial operations across various sectors.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System