Product Overview

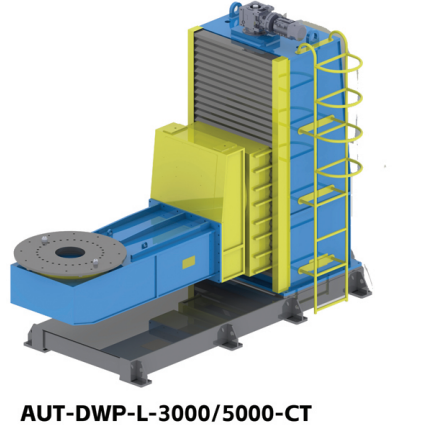

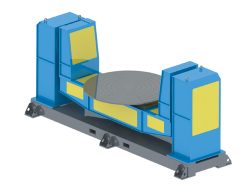

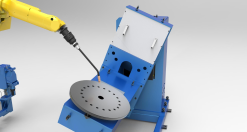

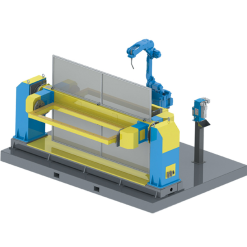

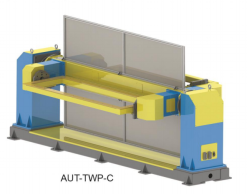

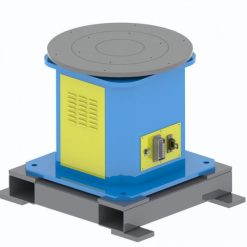

The Dual Axis Elevating L-Type Welding Positioner is an advanced positioning device developed for automated and robotic welding applications involving large and heavy workpieces.

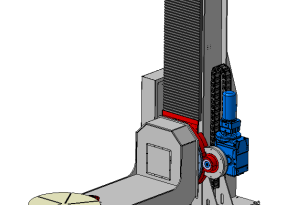

By integrating dual-axis rotational movement with a vertical lifting mechanism, the positioner enables precise adjustment of workpiece orientation and height, allowing welding robots to maintain optimal welding positions throughout the process.

Its rigid L-type mechanical structure delivers excellent load stability and vibration resistance, making it a reliable solution for high-duty welding environments and continuous production lines.

Available Models:

AUT-DWP-L-3000

AUT-DWP-L-5000

Key Advantages

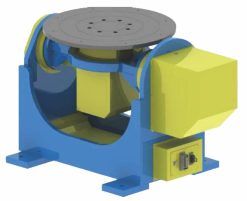

Dual-Axis Coordinated Movement

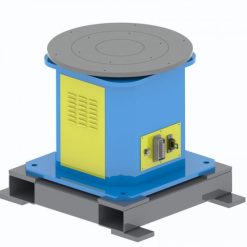

The positioner combines rotational and gyration motions to provide flexible and smooth workpiece positioning, supporting complex welding trajectories in robotic welding operations.

Vertical Height Adjustment

The integrated elevating system allows height adjustment to match different workpiece dimensions and robot reach ranges, improving welding accessibility and process ergonomics.

High Load Handling Capability

Engineered to handle payloads of up to 3000 kg or 5000 kg, the system is suitable for welding large structural components and heavy assemblies.

Rigid L-Type Structure

The reinforced L-type frame enhances overall stiffness and operational stability, ensuring consistent performance under long-duration welding conditions.

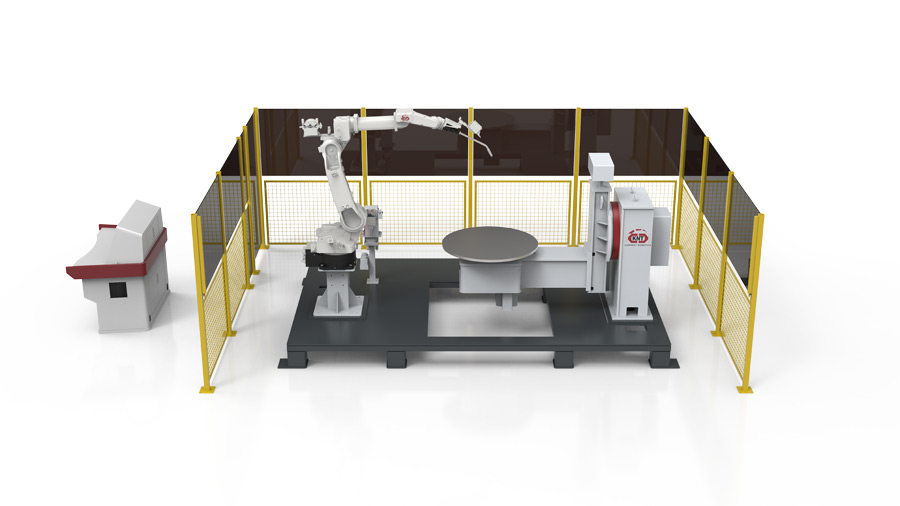

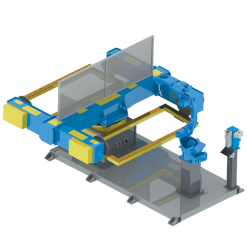

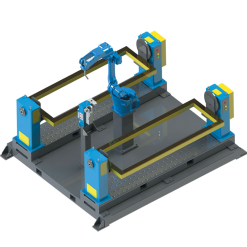

Seamless Robotic Integration

Designed for compatibility with mainstream industrial welding robots, the positioner can be easily integrated into automated welding cells and multi-station production lines.

Technical Specifications

Model: AUT-DWP-L-3000-CT / AUT-DWP-L-5000-CT

| Parameter | AUT-DWP-L-3000-CT | AUT-DWP-L-5000-CT | |

| Rated Payload | 3000 kg (countershaft axis radius ≤ R1500 mm) | 5000 kg (countershaft axis radius ≤ R2000 mm) | |

| Standard Gyration Radius | R1600 mm | R2100 mm | |

| Maximum Load Eccentricity | ≤ 750 mm | ≤ 800 mm | |

| Clamping Height | ≤ 1500 mm (counterweight required beyond this height) | ≤ 1600 mm (counterweight required beyond this height) | |

| Elevatable Stroke | 0 – 1000 mm | 0 – 1500 mm | |

| Maximum Rotation Angle (Axis 1) | ±180° | ±180° | |

| Maximum Gyration Angle (Axis 2) | ±360° | ±360° | |

| Elevating Speed | 0 – 1000 mm/min | 0 – 1000 mm/min | |

| Rated Rotation Speed (Axis 1) | 15°/s | 15°/s | |

| Rated Gyration Speed (Axis 2) | 18°/s | 18°/s | |

| Repeat Positioning Accuracy | ±0.20 mm (R = 1500 mm) | ±0.25 mm (R = 2000 mm) | |

| Overall Dimensions (L × W × H) | 3800 × 1400 × 2600 mm | 4800 × 1600 × 3200 mm | |

| Standard Gyration Disc Diameter (Axis 2) | Ø1500 mm | Ø2000 mm | |

| Gyration Disc Height | 800 – 1800 mm | 800 – 2300 mm | |

| Net Weight | Approx. 6500 kg | Approx. 10000 kg |

Typical Applications

- Robotic arc welding of large and heavy steel structures

- Automated welding of frames, beams, and fabricated assemblies

- Robotic welding lines with multiple workstations

- Welding cells requiring flexible positioning and high load capacity

Conclusion

The Dual Axis Elevating L-Type Welding Positioner is a versatile and dependable solution for robotic welding automation. By combining dual-axis motion control, vertical elevation, and a robust L-type mechanical structure, it enhances welding accessibility, improves process consistency, and increases overall production efficiency when handling large and complex workpieces.

Contact us to learn more about technical details, customization options, and robotic system integration solutions.

Ask for quote

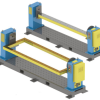

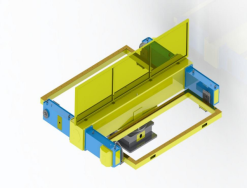

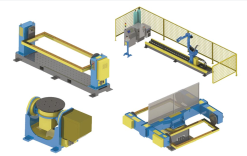

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System