Description

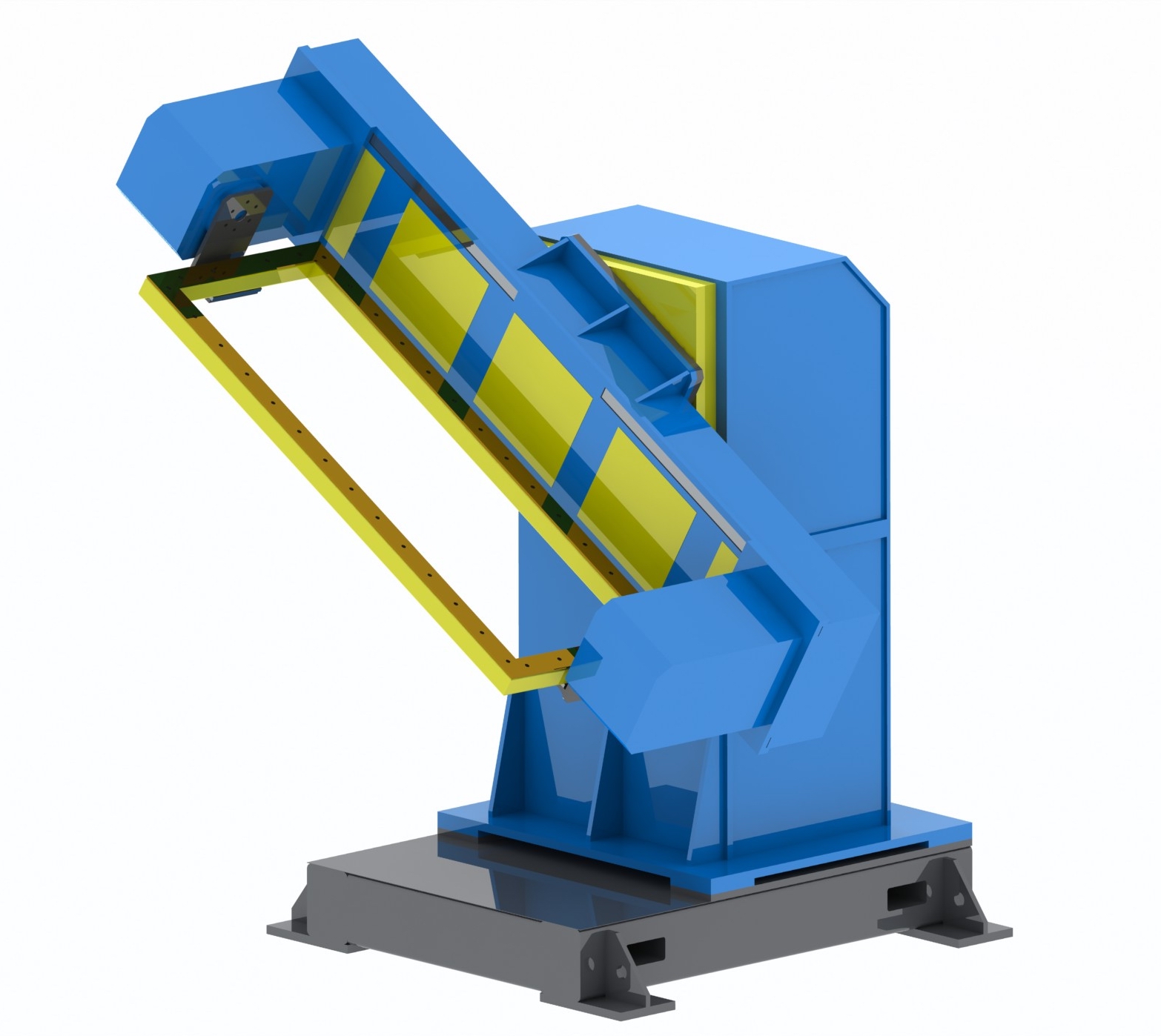

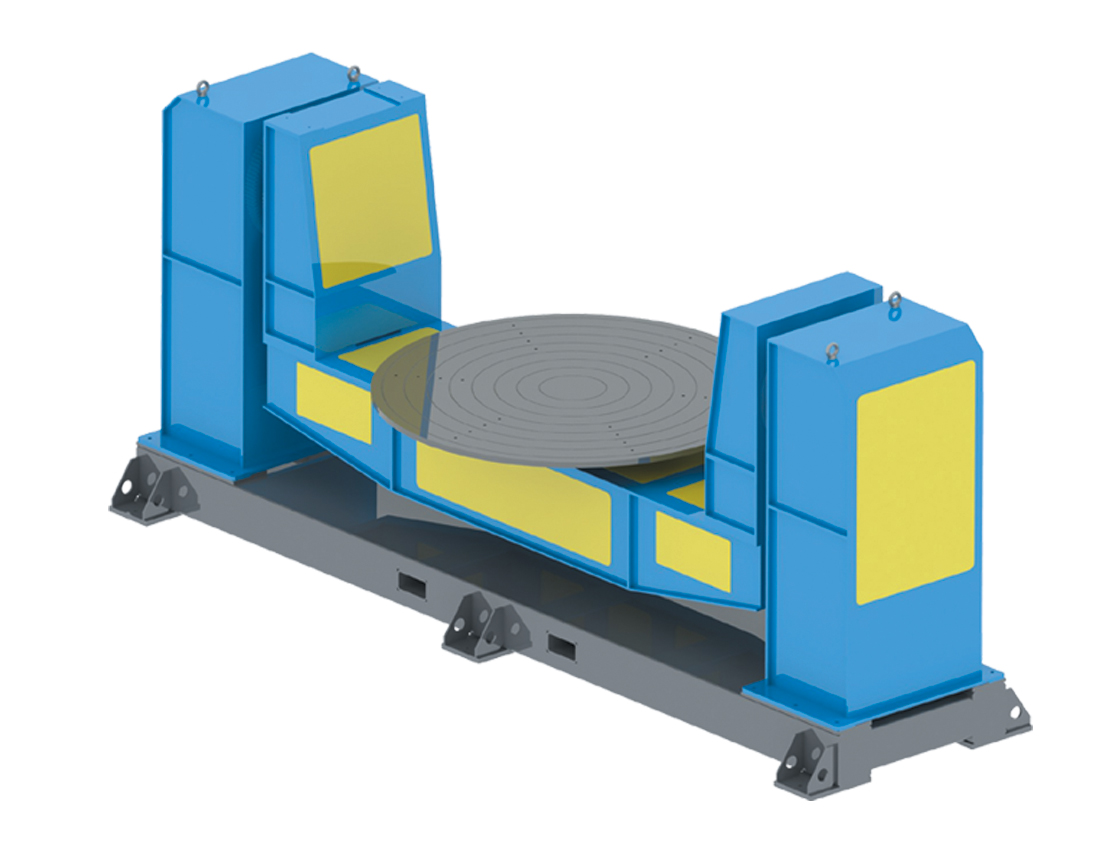

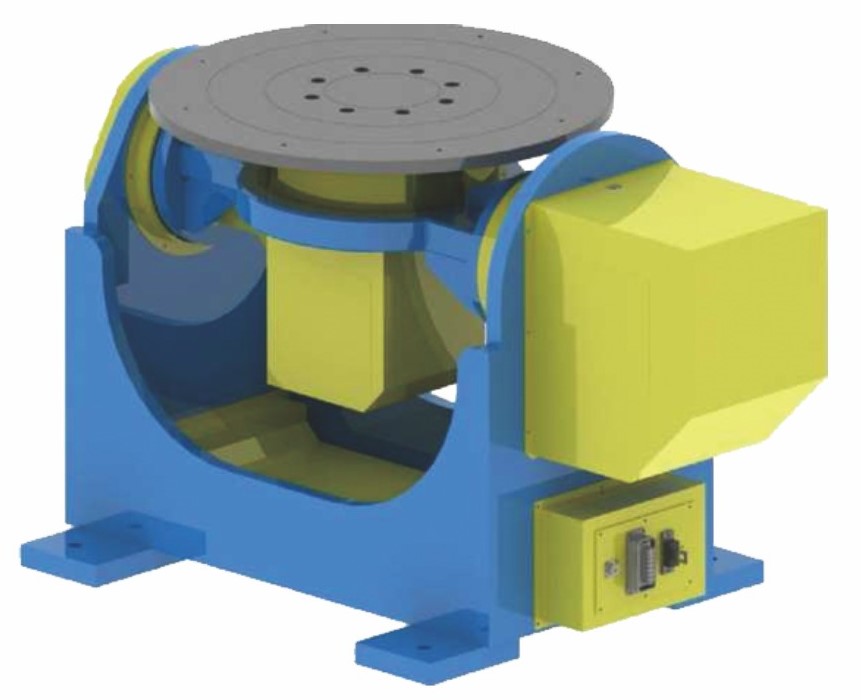

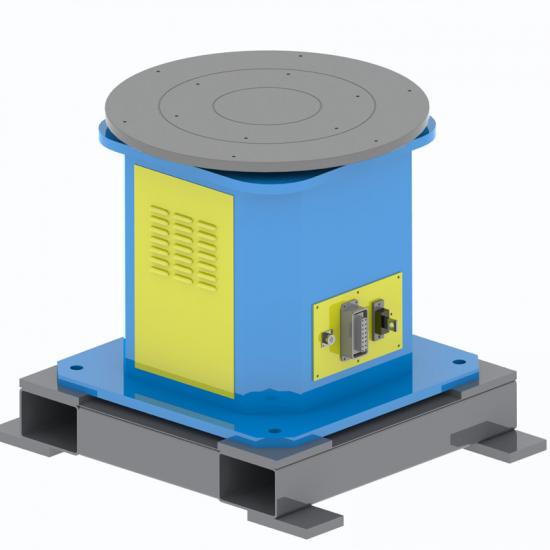

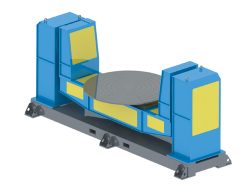

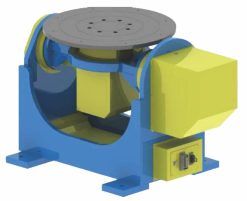

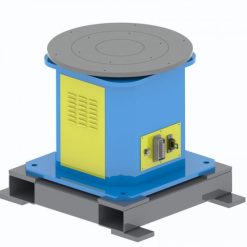

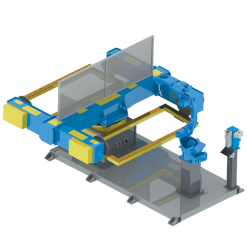

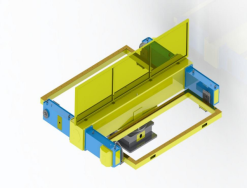

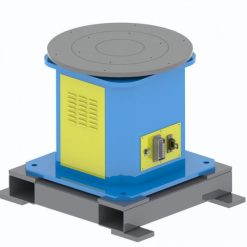

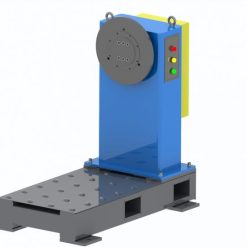

C Type Two Axis Welding Robot Servo Positioner DWP-C-500

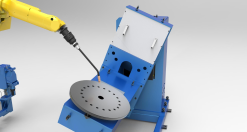

It can be matched and linked with servo motors of different robot brands, with high rotation accuracy, accurate positioning, and strong load capacity. Used in robot welding, cutting, assembly, spraying complex workpiece processing, such as flip and rotary position work

Advantages

- Improved welding quality: Robot positioners allow for precise and consistent positioning of the workpiece, which can lead to better weld quality and reduced defects.

- Increased productivity: By automating the positioning of the workpiece, robot positioners can greatly increase productivity by reducing downtime and improving cycle times.

- Reduced labor costs: Robot positioners can significantly reduce the need for manual labor in welding operations, which can help to reduce labor costs and increase efficiency.

- Improved safety: Robot positioners can help to improve safety in welding operations by minimizing the need for manual handling of heavy or awkward workpieces, reducing the risk of injury to workers.

- Flexibility: Robot positioners are highly flexible and can be programmed to handle a wide range of workpieces, making them ideal for use in a variety of welding applications.

- Consistency: Robot positioners can ensure consistent welding results by maintaining the same angle and position for each weld, reducing the likelihood of defects or inconsistencies in the finished product.

- Integration with other equipment: Robot positioners can be integrated with other welding equipment, such as welding robots, to create a fully automated welding system that can greatly improve efficiency and quality.

Specs

| No. | Item | DWP-C-200 | DWP-C-500 | DWP-C-1000 |

| 1 | Rated load | 200kg (within 2nd axis radius R400mm) | 500kg (within 2nd axis radius R400mm) | 1000kg (within 2nd axis radius R600mm) |

| 2 | Standard radius of rotary | R400mm | R400mm | R600mm |

| 3 | rotary angle of 1st axis | ±180° | ±180° | ±180° |

| 4 | rotary angle of 2nd axis | ±360° | ±360° | ±360° |

| 5 | Rated rotary speed of 1st axis | 50°/S | 50°/S | 15°/S |

| 6 | Rated rotary speed of 2nd axis | 70°/S | 70°/S | 70°/S |

| 7 | Repeated positioning accuracy | ±0.10mm | ±0.15mm | ±0.20mm |

| 8 | Dimension of the rotary frame (L×W×H) | 1200mm×600mm×70mm | 1600mm×800mm×90mm | 2000mm×1200mm×90mm |

| 9 | Positioner dimension (L×W×H) | 2000mm×1100mm×1700mm | 2300mm×1200mm×1900mm | 2700mm×1500mm×2200mm |

| 10 | Height of 1st axis rotary center | 1200mm | 1350mm | 1600mm |

| 11 | Power supply | Three phase 200V ±10% 50Hz (with isolation transformer) | Three phase 200V ±10% 50Hz (with isolation transformer) | Three phase 200V ±10% 50Hz (with isolation transformer) |

| 12 | Insulation grade | H | H | H |

| 13 | Weight | about 800kg | about 1300kg | about 2000kg |

Application

Robotic positioners are used in a wide range of industries that require welding for manufacturing and fabrication processes. Some examples include:

Automotive industry: Robotic positioners are commonly used in the automotive industry for welding car bodies and other components, such as exhaust systems and suspension parts.

Aerospace industry: The aerospace industry uses robotic positioners to weld aircraft components, such as fuselage sections, engine components, and landing gear.

Shipbuilding industry: Robotic positioners are used in shipbuilding to weld large sections of ships, including hulls, decks, and superstructures.

Construction industry: The construction industry uses robotic positioners to weld structural steel components, such as columns, beams, and trusses.

Heavy equipment manufacturing: Robotic positioners are used in the manufacturing of heavy equipment, such as bulldozers, cranes, and excavators.

Energy industry: The energy industry uses robotic positioners to weld pipelines, storage tanks, and other components used in oil and gas production, as well as renewable energy production, such as wind turbines and solar panels.

Manufacturing industry: Robotic positioners are used in a wide range of manufacturing processes that require welding, including the production of appliances, machinery, and fabricated metal products.

In general, any industry that requires welding for manufacturing or fabrication processes can benefit from the use of robotic positioners to increase efficiency, improve quality, and reduce labor costs.

Video

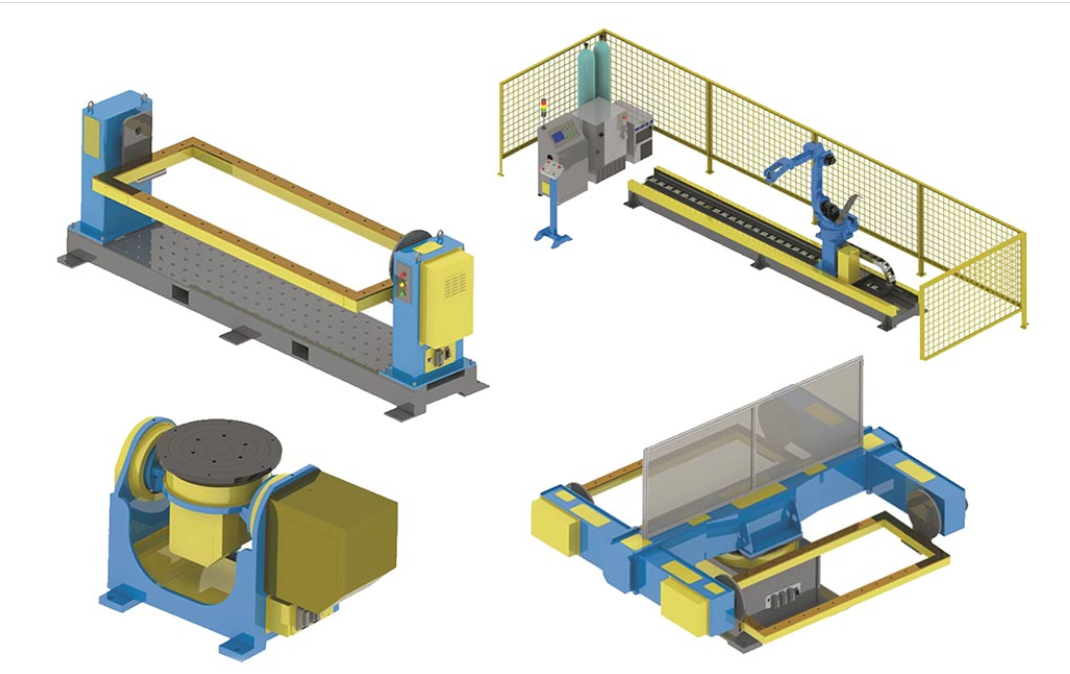

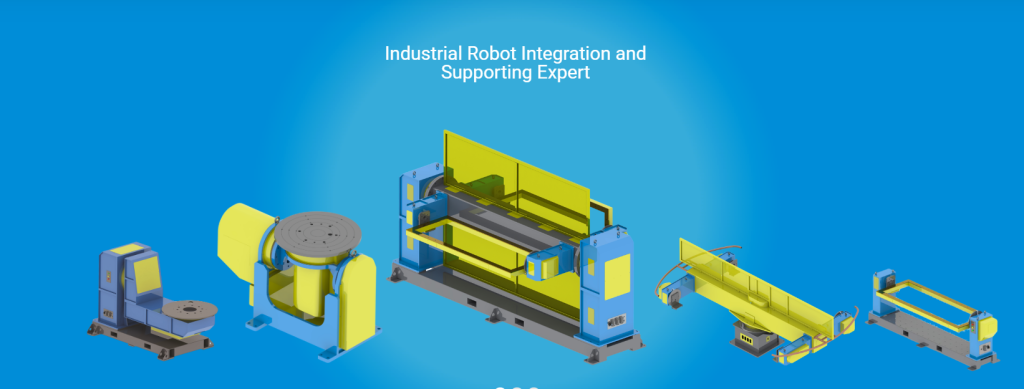

Robot Linear track

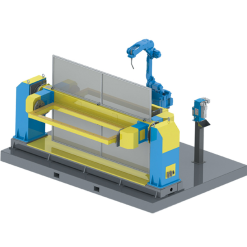

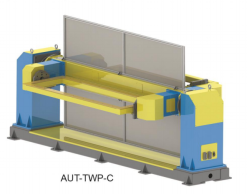

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

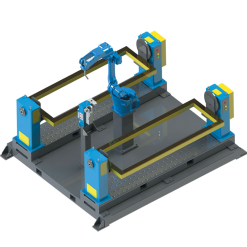

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System