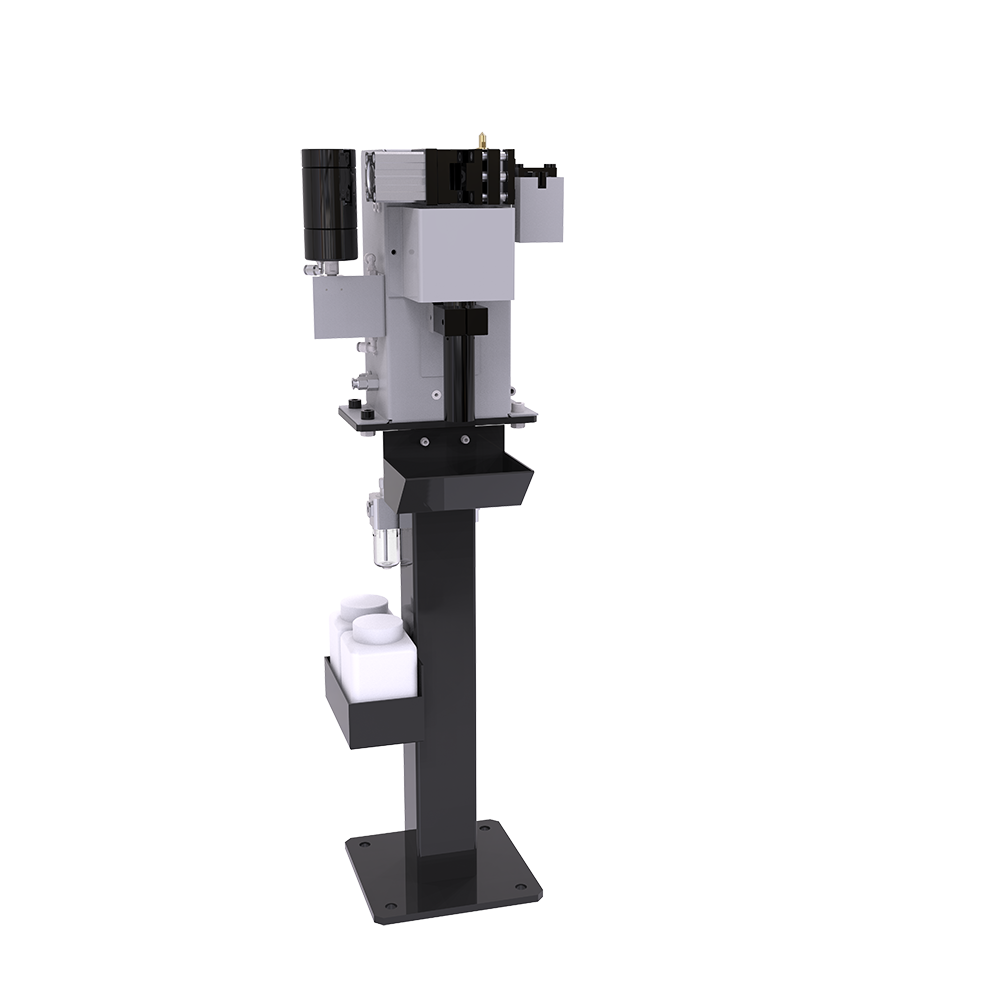

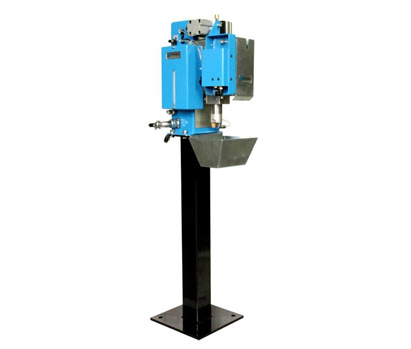

Product Overview

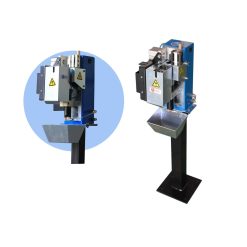

The automatic torch cleaning station is a vital auxiliary device for robotic welding automation, designed to maintain optimal welding performance. It efficiently removes welding spatter from the torch nozzle, trims excess wire, and applies anti-spatter fluid automatically. By ensuring a clean and stable welding torch, it helps maintain consistent weld quality, minimizes downtime, and prolongs the life of consumables.

This station seamlessly integrates with industrial welding robots and automated cells, supporting continuous operation in demanding production environments.

Technical Specifications

Engineered for industrial-grade reliability, the automatic torch cleaning station combines ease of integration with stable performance. Key specifications include:

| Parameter | Specification |

| Input air pressure | Clean, lubricated compressed air, 6–8 bar |

| Operating temperature | –5°C to +50°C |

| Air consumption | Approx. 6.3 L/s |

| Pneumatic motor speed | Approx. 650 rpm |

| Maximum torque | 8 Nm |

| Control voltage | 24V DC |

| Maximum control current | 0.15 A |

| Anti-spatter fluid capacity | 250 ml |

| Wire cutting capacity (solid wire) | Up to 1.6 mm |

| Wire cutting capacity (flux-cored wire) | Up to 3.2 mm |

| Wire cutting time | Approx. 0.5 s |

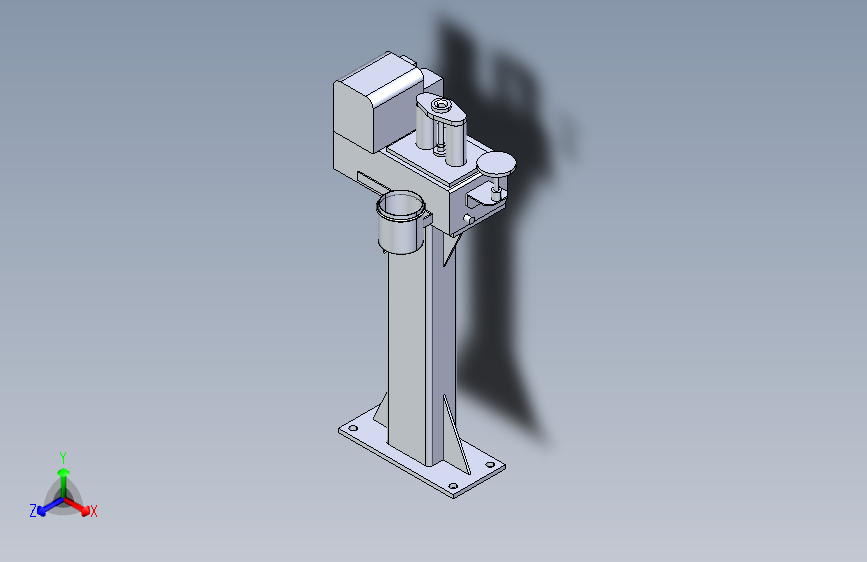

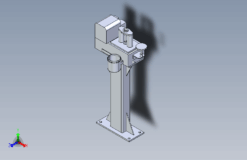

Structural Design and Main Components

The station features a compact and robust design for long-term reliability under high-frequency cleaning cycles. Its key components ensure precise torch placement, smooth operation, and simplified maintenance.

| No. | Component | Function |

| 1 | Clamping Cylinder | Automatically clamps the welding nozzle |

| 2 | Locator Block | Secures the torch nozzle |

| 3 | TCP Positioning Pin | Ensures accurate TCP alignment |

| 4 | Reamer Protective Cover | Prevents spatter from escaping |

| 5 | Motor Mounting Base | Adjusts pneumatic motor height for alignment |

| 6 | Pneumatic Motor | Drives the reamer for nozzle cleaning |

| 7 | Oil Supply Bottle | Stores anti-spatter fluid |

| 8 | Waste Oil Bottle | Collects used fluid |

| 9 | Anti-Spatter Unit | Sprays anti-spatter agent onto the nozzle |

| 10 | 8-pin Aviation Plug | Interface for robot control signals |

| 11 | Air Connection Port | Connects 8 mm air line |

| 12 | Nozzle Cleaner Support (Optional) | Adjusts cleaner height |

| 13 | Wire Shearing Device | Cuts excess welding wire |

| 14 | Welding Slag Collection Box | Collects slag and residue |

| 15 | Air Source Processing Unit (Optional) | Provides dry, lubricated air |

Design highlights:

- Adjustable motor base ensures precise reamer alignment

- Locator blocks and positioning pins guarantee repeatable torch placement

- Protective covers minimize debris buildup

- Integrated waste collection system enhances cleanliness

This optimized structure reduces vibration and delivers consistent cleaning performance, even during continuous operation.

Reamer System and Compatibility

The reamer assembly is the core unit for internal nozzle cleaning. Powered by a pneumatic motor, it rotates steadily to remove spatter without damaging the nozzle. Multiple reamer sizes are available, accommodating different nozzle inner diameters and ensuring compatibility with a wide range of robotic welding torches.

| Nozzle Inner Diameter (mm) | Contact Tip Outer Diameter (mm) | Reamer Outer Diameter (mm) | Reamer Inner Diameter (mm) | Pneumatic Model | Electric Model |

| 10 | 6 | 9 | 7 | ANC-0907-40 | ENC-0907-40 |

| 11 | 6 | 10 | 7 | ANC-1007-40 | ENC-1007-40 |

| 12 | 6 | 11 | 7 | ANC-1107-40 | ENC-1107-40 |

| 13 | 6 | 12 | 7 | ANC-1207-40 | ENC-1207-40 |

| 13 | 8 | 12 | 9 | ANC-1209-40 | ENC-1209-40 |

| 14 | 8 | 13 | 9 | ANC-1309-40 | ENC-1309-40 |

| 15 | 8 | 14 | 9 | ANC-1409-40 | ENC-1409-40 |

| 16 | 8 | 15 | 9 | ANC-1509-40 | ENC-1509-40 |

| 17 | 10 | 16 | 11 | ANC-1611-40 | ENC-1611-40 |

| 18 | 10 | 17 | 11 | ANC-1711-40 | ENC-1711-40 |

Integrated Functions

The torch cleaning station combines several functions to maximize efficiency and welding consistency:

- Automatic wire trimmingto remove residual wire after cleaning

- Anti-spatter applicationto prevent spatter adhesion on the nozzle

- Robot-synchronized operationfor fully automated cleaning cycles

These features stabilize arc ignition, reduce maintenance, and improve weld quality.

Key Benefits

- Durable mechanical structure for long-term industrial use

- Accurate torch placement with high repeatability

- Efficient spatter removal with optimized reamer design

- Wide compatibility with different nozzle sizes

- Integrated cleaning, wire cutting, and anti-spatter spraying

- Simple integration with robotic welding systems

Applications

This torch cleaning station is ideal for robotic welding cells in automotive manufacturing, metal fabrication, heavy machinery, and industrial equipment production. It ensures consistent weld quality and supports long-term automated operation.

Conclusion

The automatic torch cleaning station is an indispensable tool for maintaining stable welding performance in robotic systems. Its precise positioning, robust design, and versatile reamer compatibility help manufacturers improve welding consistency, minimize downtime, and extend the life of consumables.

Contact us now to learn more about integrating this system into your robotic welding line。

Ask for quote

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System