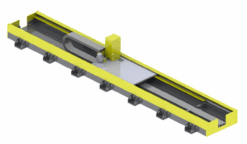

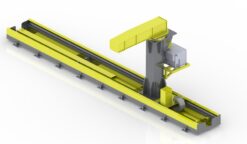

Robot linear tracks and robot sliders are automation solutions designed to extend the working range and flexibility of industrial robots. By adding a linear axis—often referred to as a 7th axis—robots can move along long distances, enabling them to serve multiple workstations or cover large work areas with high precision.

Our robot linear track and slider systems feature rigid steel structures, precision guide rails, and high-performance drive systems to ensure smooth motion, accurate positioning, and long-term stability. They are widely used in welding lines, material handling, machine tending, assembly, and palletizing applications.

Compatible with major robot brands, robot sliders and linear tracks can be customized in stroke length, payload capacity, speed, and mounting method to meet different production requirements. Integrated safety systems, cable management, and intelligent control options allow easy integration into existing automation lines.

Whether for compact production cells or large-scale factory automation, robot linear track and slider systems help maximize robot utilization, improve productivity, and optimize manufacturing efficiency.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

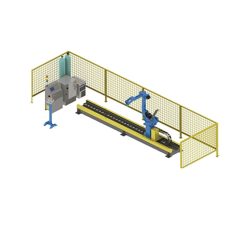

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

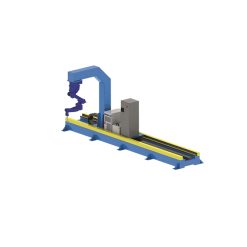

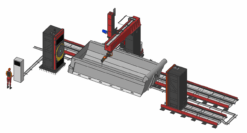

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System