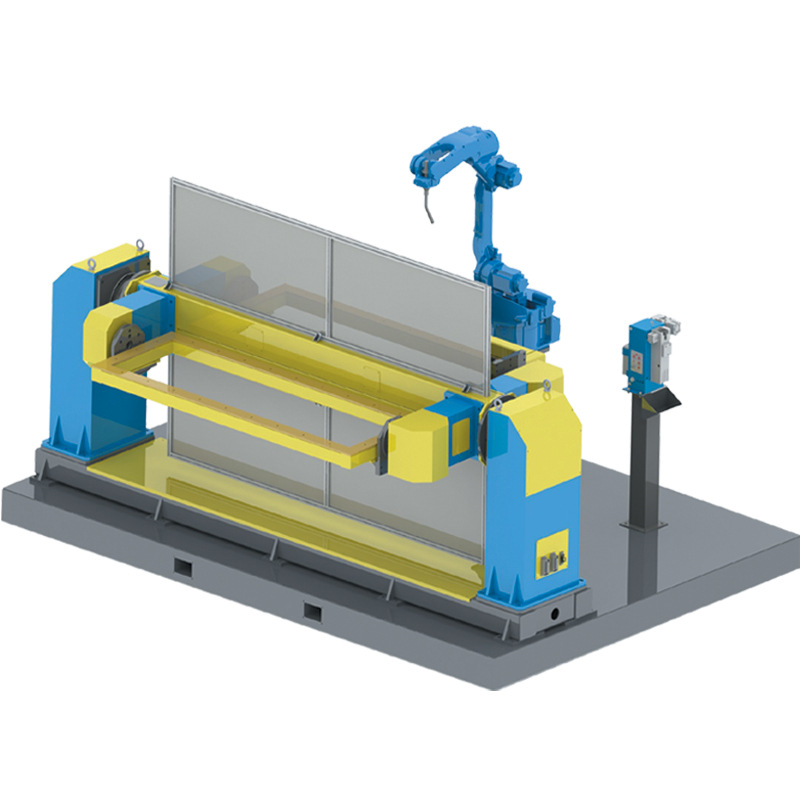

At WRS Robotics, we are proud to offer the WRS Robot Positioner and Robot Slider, a versatile gantry system series designed to meet the unique needs of our customers’ projects. With our expertise in robotics and automation, we provide customized solutions that deliver exceptional performance and precision.

The WRS Robot turntable and robot track series offers a range of advanced features and capabilities, making it an ideal choice for a variety of applications. Whether you require high-speed positioning, heavy payload handling, or precise movement control, our gantry systems can be tailored to meet your specific requirements.

Key Features of the WRS Robot Positioner and Slider:

- Customization: We understand that every project is unique. That’s why our gantry systems can be fully customized to suit your application needs. From the dimensions and payload capacity to the control interfaces and mounting options, we work closely with you to design a solution that perfectly aligns with your project goals.

- Precision and Accuracy: Our gantry systems are engineered to deliver exceptional precision and accuracy. With high-quality components and advanced motion control algorithms, you can rely on our systems to achieve precise positioning, smooth motion, and repeatable results, even in demanding production environments.

- Flexibility and Versatility: The WRS Robot welding table and track series offers flexibility in terms of configuration and adaptability to various tasks. Whether you need linear motion, rotational movement, or a combination of both, our gantry systems can be configured to accommodate your specific application requirements.

- Durability and Reliability: We prioritize the durability and reliability of our gantry systems to ensure long-term performance and minimal downtime. Built with robust materials and incorporating industry-leading engineering practices, our systems are designed to withstand rigorous operational demands and provide consistent performance over time.

- Seamless Integration: Our gantry systems are designed for seamless integration with robotic arms, end effectors, and other automation equipment. They can be easily integrated into existing production lines or incorporated into new automation setups, allowing for efficient collaboration between the gantry system and other components.

- Expert Support: At WRS Robotics, we provide comprehensive support throughout the entire project lifecycle. Our team of experienced engineers and technicians will assist you from initial concept development to installation, training, and ongoing technical support. We are committed to ensuring your success and satisfaction with our gantry systems.

Robot positioner series

Partner with WRS Robotic for Your Customized Gantry System Needs

When it comes to robotics and automation, precision and reliability are paramount. With the WRS Robot Positioner and Guide Rails series, we offer a range of gantry systems that can be tailored to your specific project needs. Partner with us to benefit from our expertise, innovative solutions, and commitment to delivering exceptional results.

Contact us today to discuss your project requirements and explore how our gantry systems can enhance your automation processes. Let us be your trusted partner in achieving efficiency, productivity, and success in your industry.

Guide rail for robots

Different types of robot track systems are available

Wheeled Track Systems: These track systems consist of wheels attached to a chassis, allowing the robot to move on flat or slightly uneven surfaces. They are commonly used in applications where speed and maneuverability are essential, such as warehouse logistics, indoor navigation, and autonomous vehicles.

Tracked Track Systems: Tracked systems use continuous tracks or treads to provide enhanced traction and stability on various terrains. They are commonly found in off-road or rugged environments where wheel-based systems may struggle to navigate, such as construction sites, agriculture, or military applications.

Legged Track Systems: Legged track systems combine the benefits of both legs and tracks. They utilize legs for stability and track-like mechanisms for locomotion. These systems are designed to traverse challenging terrains, including uneven surfaces, stairs, or obstacles. Legged track systems are often used in search and rescue operations, exploration, or military applications.

Omni-Directional Track Systems: Omni-directional track systems enable robots to move in any direction without changing their orientation. They use specialized wheels or tracks that allow for simultaneous translation and rotation. These systems are advantageous in applications that require precise maneuvering or navigating tight spaces, such as manufacturing assembly lines or mobile robotics.

Hybrid Track Systems: Hybrid track systems combine different types of locomotion mechanisms, such as wheels, tracks, or legs, to provide versatility and adaptability to various environments. These systems can switch between different modes of locomotion based on the terrain or operational requirements. Hybrid track systems are often used in advanced robotics research, exploration missions, or specialized applications that demand flexibility.

These are just a few examples of the diverse range of track systems available in the market. Each type has its own advantages and suitability for specific applications. When choosing a track system, it’s important to consider the specific requirements of your application and select the one that best addresses your mobility needs, terrain conditions, payload capacity, and operational constraints.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System