1.1 Advantages and Importance of Welding Positioners

Are you looking for a reliable and efficient solution for your welding needs? Consider a robotic welding positioner. Improve your welding process with a consistent and precise positioning system that delivers quality and productivity.

As a key welding automation equipment, the welding positioner has a wide range of applications in the welding industry. In this paper, we will discuss the main uses of welding rotator and its unique advantages, and introduce its important role in improving welding quality, enhancing productivity, and ensuring worker safety. Welding Workpiece positioner provides an efficient and precise operation platform for the welding process through its flexible variable-position transmission mechanism and precise motion control, which promotes the development of welding automation. At the same time, welding turntable also has the advantages of high flexibility, consistency, and reliability, which brings great benefits to various industries.

Welding is an important connection process in the manufacturing industry, the traditional manual welding there are problems of low efficiency, unstable quality, and high labor intensity. Welding positioners, as an important part of welding automation equipment, have revolutionized the welding industry.

The main applications of the welding positioner

2.1 Automated welding

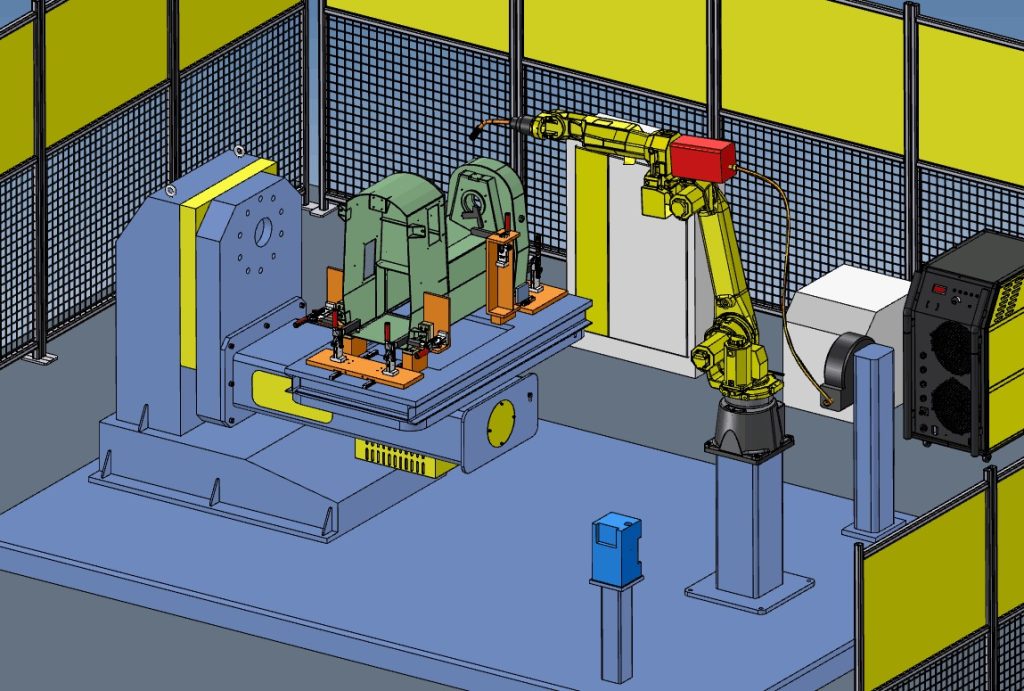

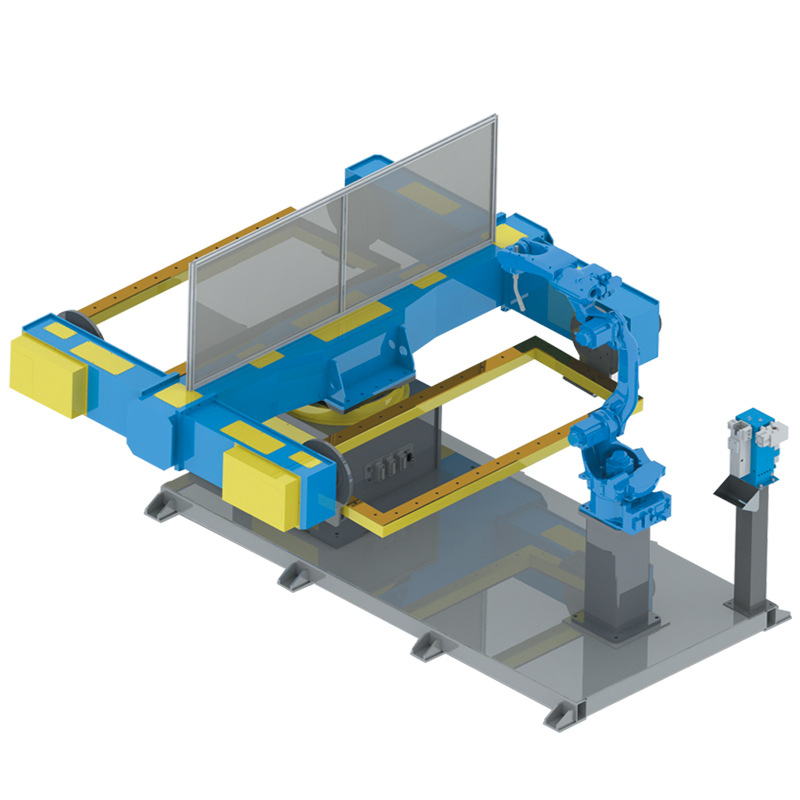

A welding positioner is widely used in automated welding systems, which can realize the positioning, transposition, and attitude adjustment of welding workpieces. Through the fast and accurate motion control of the positioner, efficient and stable welding operation can be realized, and the welding quality and production efficiency can be improved.

2.2 Multi-station welding

In the multi-station welding process, the Welding Rotary Positioner is used to realize the rapid transfer of workpieces between different workstations. The high speed and high precision of the Rotary Positioner ensure accurate positioning and stable transfer of the workpiece, improving the efficiency and consistency of multi-station welding.

2.3 Complex welding tasks

For complex welding tasks, such as curved surface welding and multi-angle welding, the welding rotator is able to realize multi-directional adjustment and positioning of the welding head through its flexible variable-position drive mechanism. This high degree of flexibility and precision enables the welding positioning tables to cope with a wide range of complex welding requirements

Advantages of the Welding Positioner

3.1 High flexibility

The welding positioner is able to realize multi-directional and multi-angle welding operations through its multi-axis variable position drive structure. This makes the welding indexer highly adaptable to different welding processes and workpiece shapes.

3.2 High precision and stability

The welding Workpiece positioner has precise motion control capability, which can realize high-precision welding operation. Its stable structural design and advanced control system ensure the stability and consistency of the welding process and improve the welding quality.

3.3 Improve production efficiency and personnel safety

The automated operation of the welding positioner can significantly improve the efficiency of the welding production line. At the same time, giving the welding task to the robot operation can reduce the risk of direct contact and exposure of workers to high temperatures and harmful gases, and improve the safety of the workplace.

As welding technology and automation technology continue to advance, the welding poser will evolve further. The future welding turntable will be more intelligent, flexible, and reliable, able to adapt to more complex welding tasks and achieve a higher degree of integration with other intelligent equipment.

As key equipment for welding automation, the welding turntable plays an important role in the welding industry. Its diverse application fields and unique advantages promote the improvement of welding quality, productivity, and worker safety. With the continuous progress of technology, ROBOT WELDING POSITIONER will continue to evolve and bring more innovation and progress to the welding industry.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System