Robot 7th axes—also called robot linear track or external axes—are game-changers when it comes to extending a robot’s reach. But picking the right one isn’t just about matching specs on paper; it needs to align closely with your robot’s load capacity, workflow, and precision requirements. Before diving into options, ask yourself two critical questions:

What’s the end goal?

Are you moving parts long distances, welding large surfaces, or handling multi-station assembly? Each task puts very different demands on load capacity and speed. Then, which robot will it pair with? Whether it’s a 6-axis robot, SCARA model, or collaborative unit, the robot 7th axis must sync up with the robot’s interface and weight limits to avoid compatibility headaches.

Let’s break down the seven key factors that separate successful selections from costly missteps—no overly technical jargon, just practical insights.

1.Load capacity isn’t just about static weight. Sure, you need a model that can handle the robot’s own weight plus its maximum workload—always leave a 10-20% safety buffer. But what often gets overlooked is dynamic load: the inertial forces when the robot moves. This is especially critical for high-speed operations. Pay close attention to the rail’s rigidity—things like guideway material and support structures can make or break stability.

2.When it comes to stroke length, balance is everything. Calculate the minimum required stroke based on your production line’s length and station spacing. Too short, and you’ll limit what the robot can do; too long, and you’re wasting money on unused capacity. For longer strokes (over 5 meters), cumulative error becomes a problem. Look for models with error compensation features to keep end-point precision from dropping off.

3. Precision and speed need to work in tandem—not just chase the highest numbers. Repeat positioning accuracy should match your process: assembly tasks might call for ±0.05mm or better, but regular material handling can get by with ±0.5mm. Overinvesting in precision will hike costs unnecessarily. Similarly, the axis’s speed must sync with the robot’s cycle time. You don’t want the robot waiting on the axis, or vice versa. Crunch the numbers on single-cycle times to keep overall efficiency on track.

4. Guideway type depends heavily on your workspace environment and load. Ball rails offer tight precision and low friction—perfect for clean settings like electronics or pharmaceutical plants—but they struggle with dust. Roller rails, on the other hand, are tough, contamination-resistant, and low-maintenance, making them ideal for harsh environments like automotive welding or casting. For long strokes and heavy loads, gear rack rails are the way to go—just don’t forget to check rack precision and lubrication needs.

5. Stability should be your top priority when choosing a drive system. Servo drives deliver the accuracy and fast response needed for high-precision tasks, while stepper drives are more budget-friendly for low-speed, low-precision applications. Sizing the motor correctly is key too: too small, and it’ll overload; too large, and you’re wasting energy. Heat dissipation is another consideration, especially in high-temperature workspaces.

6. Your 7th axis needs to stand up to your working conditions. At minimum, aim for IP54 protection (dust and water splatter resistance) in standard environments. For damp or dusty settings, bump that up to IP65 or IP67. Welding applications demand high-temperature materials—think stainless steel guideways and heat-resistant cables—while chemical or corrosive environments call for anti-corrosion coatings.

7. Don’t forget about compatibility and future growth. The 7th axis’s communication interfaces (like Profinet or EtherCAT) need to play nice with your robot’s control cabinet and production line PLC to avoid communication glitches. If you might add more robots later—say, two robots sharing a single rail—opt for a model that supports multi-robot coordination. It’ll save you from costly retrofits down the line.

Once you have picked a model, take these steps to avoid on-site issues. Whenever possible, ask the manufacturer for load and precision test data, 3D models, or a live demo. Get clarity on maintenance:

A.How often does the guideway need lubrication?

B. What’s the cost of replacing wear parts?

C. And don’t skimp on technical support—look for manufacturers that offer installation guidance, debugging help, and quick after-sales response, especially for complex setups.

Choosing a 7th axis isn’t about grabbing the model with the fanciest specs or the lowest price. It’s about closing the loop between your actual needs, parameter matching, and long-term costs. Start with your workflow goals and environment constraints, narrow down options using load, stroke, and precision, then factor in compatibility and maintenance. Cut corners or chase unnecessary features, and you’ll end up with downtime, inefficiency, or expensive rework.

Whether you’re automating a small assembly line or scaling up a large manufacturing floor, getting the robot 7th axis right turns your robot into a more flexible, productive asset. Take the time to align specs with real-world needs—your bottom line will thank you.

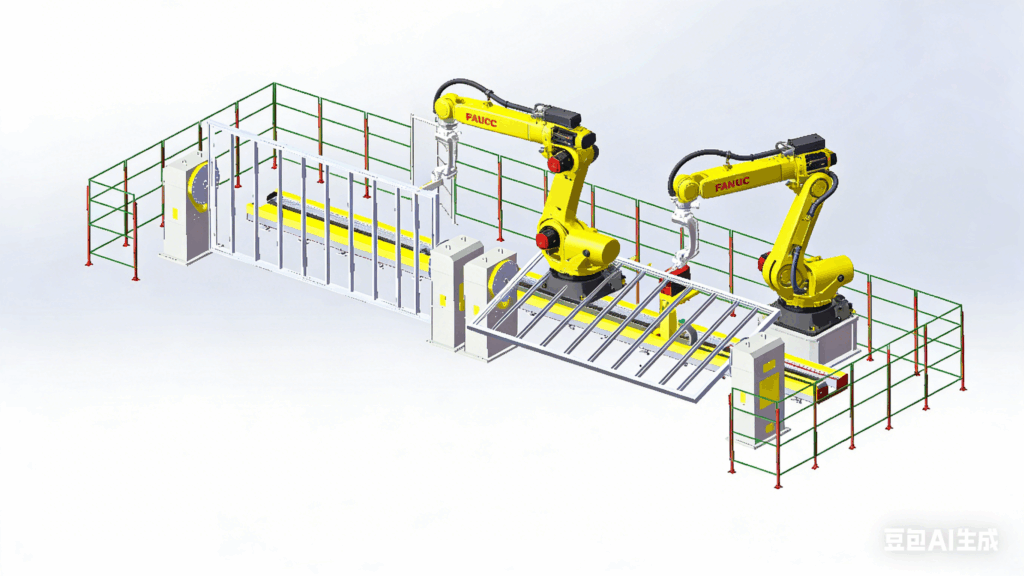

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System