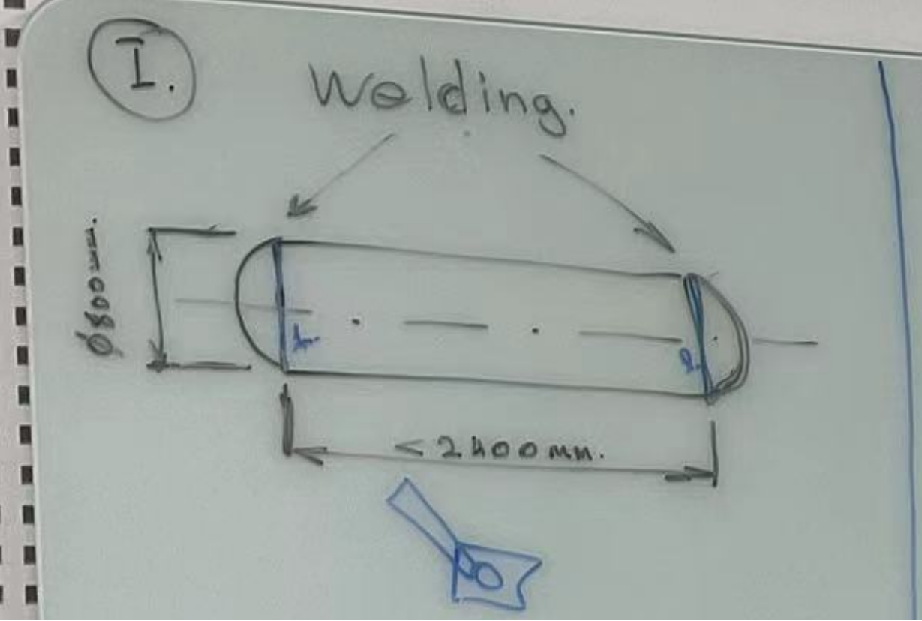

1. Customer Requirement

We need to design a welding auxiliary device that can meet the requirements of carbon steel material: a cylinder with a diameter of 800mm and a length of 2400mm or 1500mm, and welding with hemispherical workpieces at both ends;

2. Workpiece size

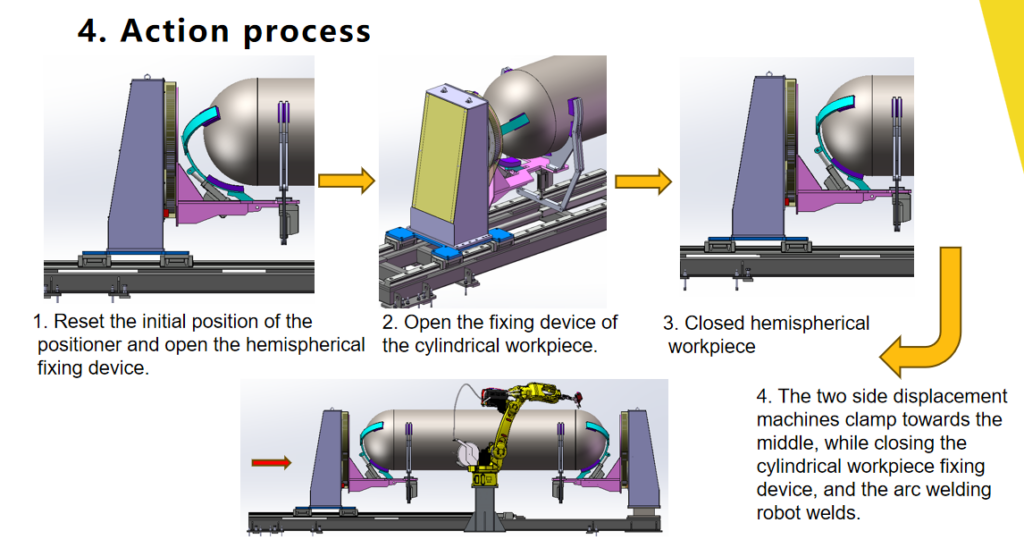

5. Welding Robot Automation Process for Welding Cylinders

1.Design and Fixture Preparation:

2. Programming the Welding Robot:

3. Cylinder Loading and Positioning:

4. Welding Process Execution:

5. Quality Control and Inspection:

6. Post-Welding Operations:

7. Unloading and Material Handling:

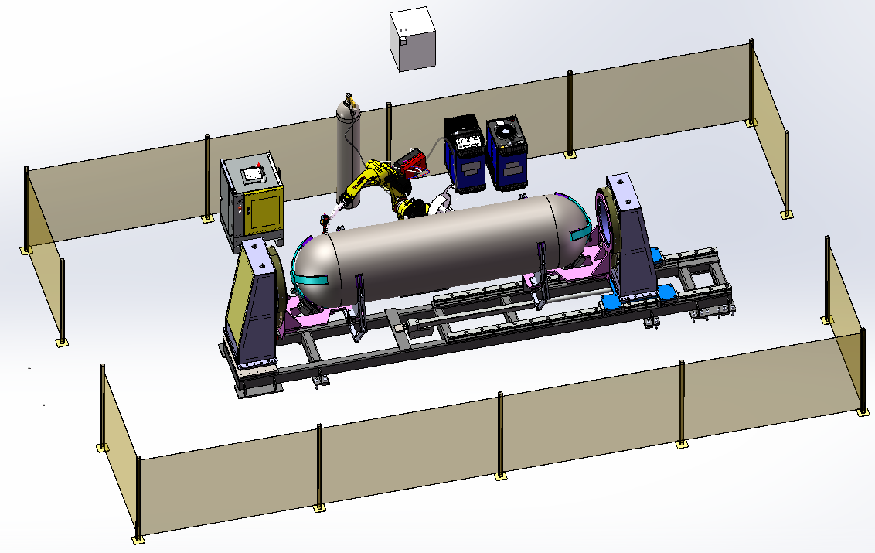

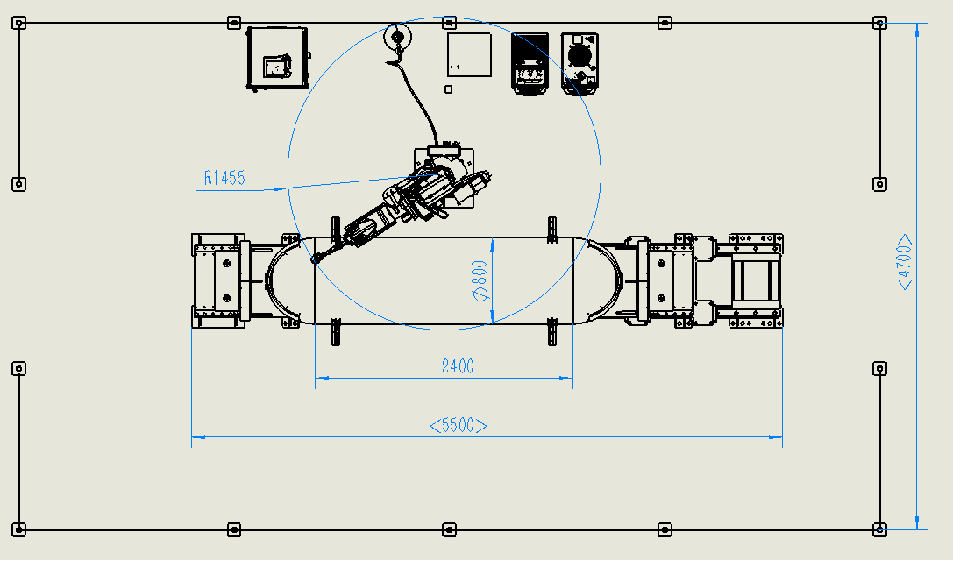

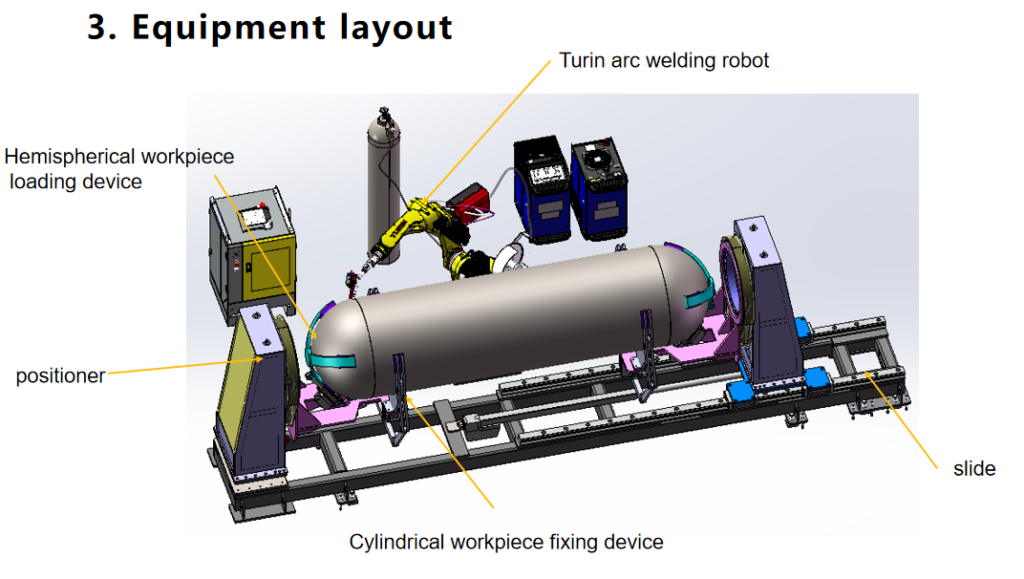

6. Configuration checklist

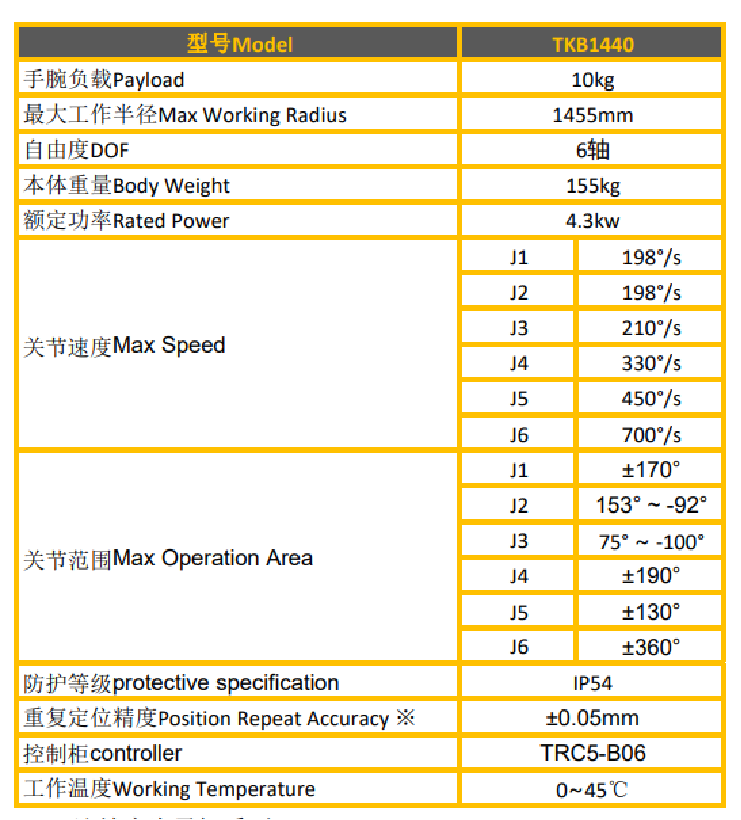

| Component | Model | Notes | Quantity |

| welding robot | TKB1440 | Chinese robot | 1 |

| positioner | 2 | ||

| Welding machine, material tray | 1 | ||

| Gas cylinder | 1 | ||

| linear actuator_a | 2 | ||

| linear actuator_b | 2 | ||

| linear actuator_c | 1 | ||

| rail | 2 | ||

| Machined parts | Non standard customization | 1series |

Don’t hesitate to reach out to us for comprehensive turnkey solutions tailored to meet your specific robotic automation integration needs!

At WRS Robotics, we specialize in providing end-to-end turnkey solutions for all types of robotic automation integration projects. Whether you require assistance with design, programming, installation, or ongoing support, our team of experts is ready to collaborate with you every step of the way.

Our Services Include:

1. Consultation and Project Assessment:

We begin by understanding your unique requirements and goals. Our experienced professionals will assess your automation needs, evaluate existing processes, and provide expert recommendations to optimize your workflow.

2. Customized System Design:

Our team will design a customized robotic automation solution that aligns with your specific project objectives. We carefully consider factors such as workspace layout, production volume, cycle time requirements, and safety protocols to develop an efficient and reliable system.

3. Robot Selection and Integration:

Leveraging our extensive knowledge of robotic systems, we will help you select the most suitable robot or robotic system for your application. We have expertise in integrating a wide range of robots, including industrial robotic arms, collaborative robots (cobots), and specialized robotic solutions.

4. Programming and Simulation:

Our skilled programmers will develop precise and optimized robot programs tailored to your automation requirements. We utilize advanced simulation software to validate and optimize the robot’s path, cycle time, and collision-free operation before implementation.

5. Installation and Commissioning:

Our experienced technicians will handle the installation and commissioning of the robotic automation system on-site. We ensure seamless integration with your existing equipment, conduct thorough testing and provide comprehensive training to your staff for efficient operation.

6. Ongoing Support and Maintenance:

We provide continuous support after the implementation of your robotic automation system. Our team offers regular maintenance, troubleshooting, and software updates to ensure smooth and uninterrupted operation. We are committed to maximizing the performance and longevity of your automation investment.

With our turnkey solutions, you can streamline your operations, increase productivity, and achieve significant cost savings. We have a proven track record of successfully integrating robotic automation across various industries, including manufacturing, logistics, automotive, and more.

Contact us today to discuss your robotic automation integration project. Our dedicated team is ready to collaborate with you, providing expertise, innovation, and exceptional service to bring your automation vision to reality.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System