The content of the article directory mainly introduces the robot positioner, its features, application, and advantages.

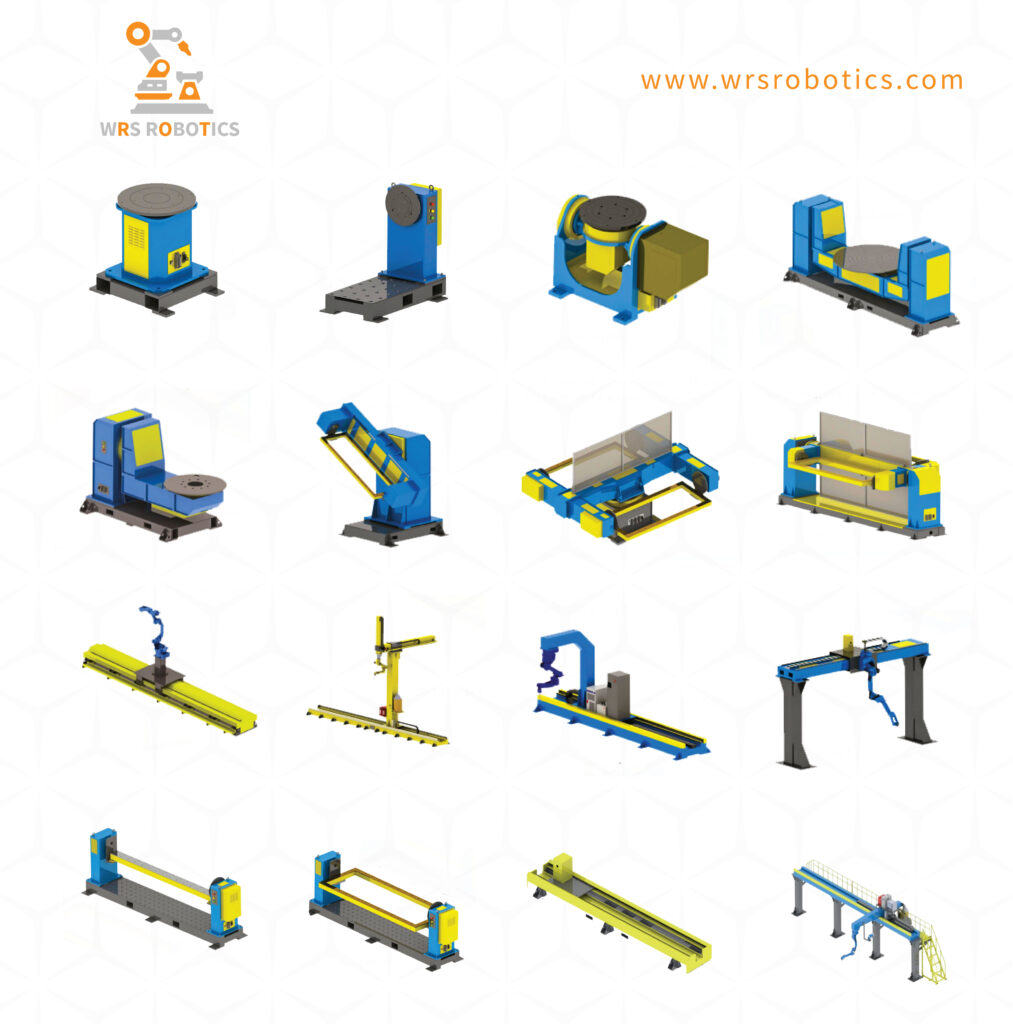

Welcome to China’s advanced automation with our cutting-edge robot positioners, linear tracks, and gantry systems. Our company is at the forefront of revolutionizing industrial robotics, providing innovative solutions that enhance precision, flexibility, and productivity. Whether you are seeking precise positioning for intricate tasks, an expanded workspace for large-scale operations, or robust gantry systems for heavy-duty applications, our comprehensive range of products has you covered. With a commitment to delivering exceptional quality and performance, we invite you to explore the possibilities and discover how our state-of-the-art automation solutions can elevate your manufacturing processes to new heights.

In the realm of industrial automation, there’s a game-changer that is revolutionizing manufacturing processes—robot positioners. These advanced devices offer precise motion control, versatility, and a wide range of applications. we will explore the characteristics, applications, and advantages of robot positioners, shedding light on their transformative potential in the world of industrial automation.

Characteristics of Robot Positioners:

High-Precision Motion Control: Robot positioners boast exceptional motion control capabilities, enabling precise positioning and manipulation of robotic arms or end-effectors. With their impressive accuracy, they execute complex tasks with efficiency and consistency.

Multi-Axis Freedom: These positioners provide multi-axis freedom, empowering them to perform intricate movements. They can rotate, tilt, and translate in multiple directions, adapting to the varying requirements of diverse industrial applications.

Payload Capacity: Designed to handle different payload capacities, robot positioners offer the strength and stability necessary to support and maneuver heavy loads. Whether it’s delicate components or substantial workpieces, these positioners excel in accommodating various weights.

Versatile Mounting Options: With their adaptable mounting options, robot positioners seamlessly integrate with different types of robotic arms and end-effectors. This versatility ensures compatibility with a wide range of automation setups, providing flexibility in system design.

Applications of Robot Positioners:

Assembly and Manufacturing: Robot positioners are widely employed in assembly processes, facilitating precise positioning and manipulation of components. They streamline assembly line operations, reduce cycle times, and enhance product quality.

Welding and Cutting: In welding and cutting applications, robot positioners play a pivotal role. By providing optimal access and angles, they enable precise execution of welding or cutting operations, resulting in high-quality and uniform results.

Inspection and Testing: Robot positioners are utilized in inspection and testing processes, allowing for accurate positioning of sensors or probes. This enables thorough inspections, precise measurements, and stringent quality control.

Material Handling: With their ability to handle heavy or bulk materials, robot positioners optimize material handling tasks. They streamline loading and unloading operations, improving workflow efficiency and reducing manual labor.

Advantages of Robot Positioners:

Enhanced Productivity: Robot welding positioners boost productivity by streamlining operations and reducing cycle times. They minimize errors, enhance workflow efficiency, and enable faster and more efficient execution of tasks, leading to increased output and reduced production costs.

Improved Accuracy and Quality: Thanks to their precise motion control, robot positioners ensure accurate positioning and consistent performance. This results in higher product quality, reduced rework, and improved overall efficiency.

Flexibility and Adaptability: Robot positioners offer flexibility and adaptability, enabling quick reprogramming or reconfiguration for different tasks. This versatility allows manufacturers to respond rapidly to changing production demands, optimizing resource utilization.

Enhanced Workplace Safety: By automating repetitive or hazardous tasks, robot positioners enhance workplace safety. They minimize the risk of injuries associated with manual handling or exposure to dangerous environments, creating a safer work environment for human operators.

Cost-Effectiveness: Robot positioners contribute to cost savings by optimizing production processes and reducing labor-intensive tasks. They improve resource utilization, minimize material waste, and increase overall operational efficiency, resulting in long-term cost savings.

Conclusion:

Robot positioners are transforming the landscape of industrial automation with their precise motion control, versatility, and wide-ranging applications. From assembly and manufacturing to welding, cutting, inspection, and material handling, these remarkable devices offer numerous advantages. By incorporating robot positioners into manufacturing processes, businesses can unlock enhanced productivity, improved accuracy, increased flexibility, and a safer work environment. Embrace the power of robot positioners and propel your industrial automation to new heights of efficiency and success.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System