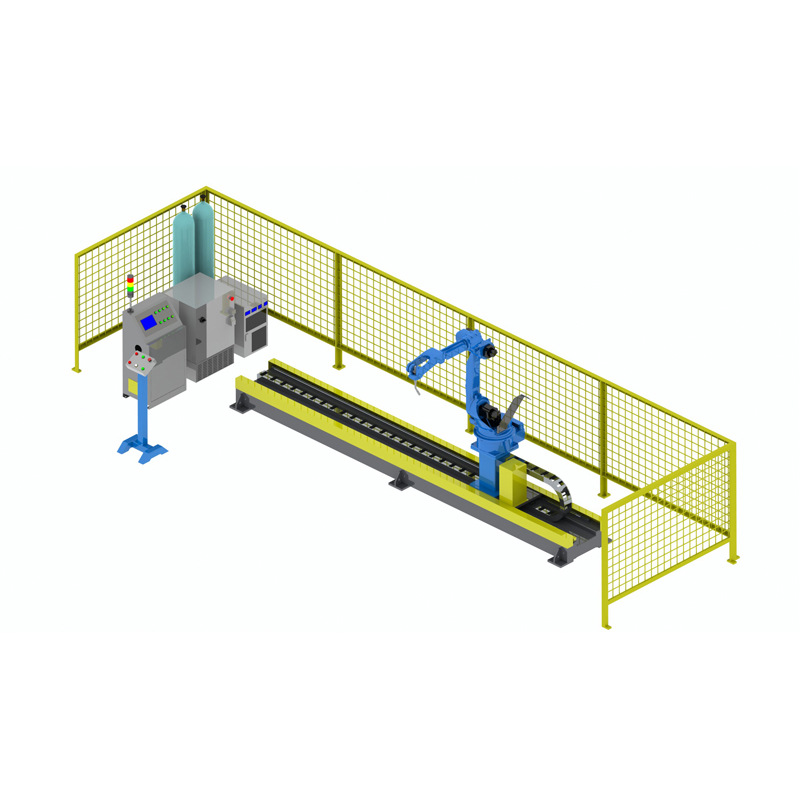

Robot guide rails are suitable for machine tool-workpiece loading and unloading, welding, assembly, spraying, inspection, casting, forging, heat treatment, metal cutting, transportation, palletizing, etc. A robot linear track can realize multi-station handling, and a robot can work with Multiple machining centers to realize automated processing processes. Users can effectively save costs and improve the working efficiency of the robot by using the industrial robot slider. It is a robot working stroke system that can realize multi-station transportation.

Robot linear track feature

1. The robot guide rail has excellent quality assurance, strong applicability (it is a robot walking axis unit that can be used in a variety of situations), simple structure, low failure rate, reliable performance, easy maintenance, high rigidity, and fast running speed. , large load, high repeatability, good protection performance, and can be customized.

2. The robot motion track occupies less space, which is conducive to the installation of production lines in end customer factories. It can be installed in a narrow space and can be effectively used after being installed on-site.

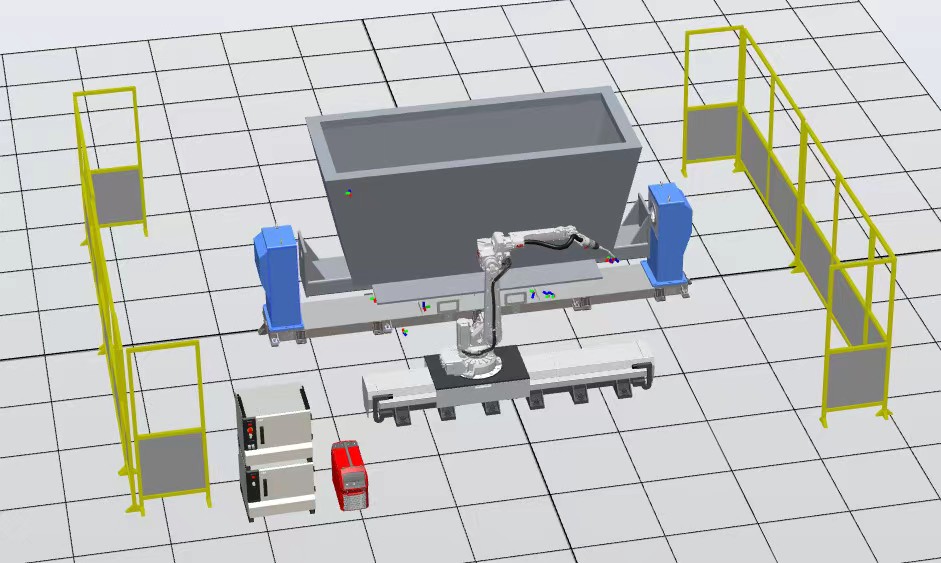

The technical issues to be confirmed when purchasing robot tracks are as follows:

1. Which robot brand and model (maybe equipped with other workpieces)?

2. What is the effective stroke, total length (mm), and combined height of the robot’s walking axis?

3. Installation method (hanging/ground installation/side-mounted installation)? Is the drag chain built-in or external?

4. Where are the robot, control cabinet, welding machine, welding wire, and other components placed (are they placed on the sliding table)? Determine the slide size.

5. Robot walking axis mode: fully closed/semi-closed/open (generally selected according to the environment and industry).

6. Total robot track payload how many KG, positioning accuracy mm, speed (m/S).

7. Confirm the installation floor, foundation bearing, and operating environment.

8. Confirmation of the entry space (is it convenient for the entry and exit of loading and unloading vehicles, and the smooth entry of the main body and tools)?

9. Is it necessary for the manufacturer to provide motors and reducers, and are there any brand requirements?

10. What are the color requirements for the robot walking track body (color number needs to be provided)?

11. What are the brand requirements for the main mechanical accessories of the robot slider (usually they are customized products for seventh-axis intelligent equipment, and the designated brand needs to be proposed)?

12. Is it required to include software electrical programming and on-site debugging?

13. Is it necessary to add other equipment (such as safety guardrails, anti-falling devices, anti-corrosion treatments, etc.)?

14. Is it required to go to the site for installation and debugging, and is transportation included?

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System