Automotive Manufacturing: Streamlining Chassis Welding with Linear Tracks

In automotive manufacturing, chassis welding sits at the heart of vehicle safety and structural integrity. Every weld matters. As production volumes continue to rise and vehicle platforms become more varied—especially with the growth of electric vehicles—many manufacturers are discovering a clear limitation: traditional fixed-base welding robots simply can’t keep up anymore.

This is where robot linear track systems come into play. By adding mobility to robotic welding, manufacturers are finding practical ways to boost efficiency, improve flexibility, and reduce overall system complexity on the shop floor.

Why Chassis Welding Is So Challenging

Anyone who has worked with chassis structures knows they are anything but simple. They are long, heavy, and packed with critical weld points that demand consistency.

One common issue is reach. A single robot often cannot cover an entire chassis without repositioning or additional equipment. To compensate, production lines end up adding more robots, which quickly drives up both capital investment and maintenance costs.

At the same time, today’s automotive plants rarely produce just one model. Mixed production and frequent model changes require flexible systems—something fixed welding stations struggle to deliver. And, of course, weld quality cannot be compromised; repeatability and consistency are non-negotiable.

All of this has pushed manufacturers to rethink how robotic welding systems are designed.

What Linear Tracks Change in Robotic Welding

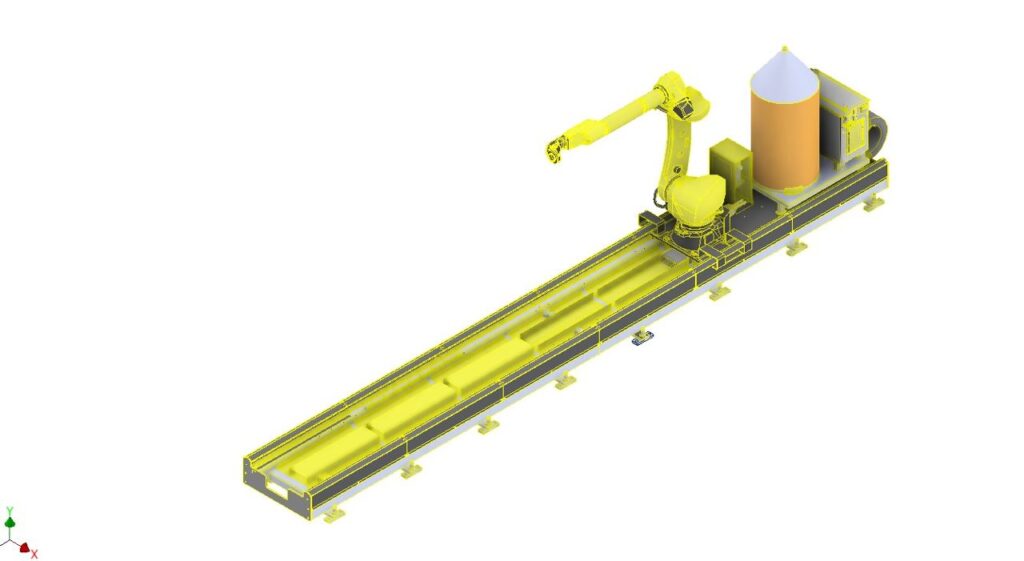

A linear track, often referred to as a robot’s 7th axis, allows the robot to move smoothly along a guided rail. Instead of working within a fixed radius, the robot can now travel across multiple welding positions.

In real production environments, this brings immediate benefits. A single robot can service several stations along a chassis line, reducing the total number of robots required. Motion becomes more fluid, cycle times shorten, and unnecessary stops are minimized.

Just as important, weld paths become more consistent. When the robot moves in a controlled, linear motion, maintaining stable torch angles and welding parameters becomes much easier—something production engineers appreciate very quickly.

When linear tracks are combined with positioners, fixtures, and well-designed welding cells, the result is a system that feels both powerful and adaptable.

Where Linear Track Welding Is Commonly Used

In automotive plants, linear track systems are already well established across a range of applications. They are frequently seen in:

-

Passenger vehicle chassis and cross-beam welding

-

EV battery tray and underbody structure welding

-

Commercial vehicles, trucks, and long-frame chassis assemblies

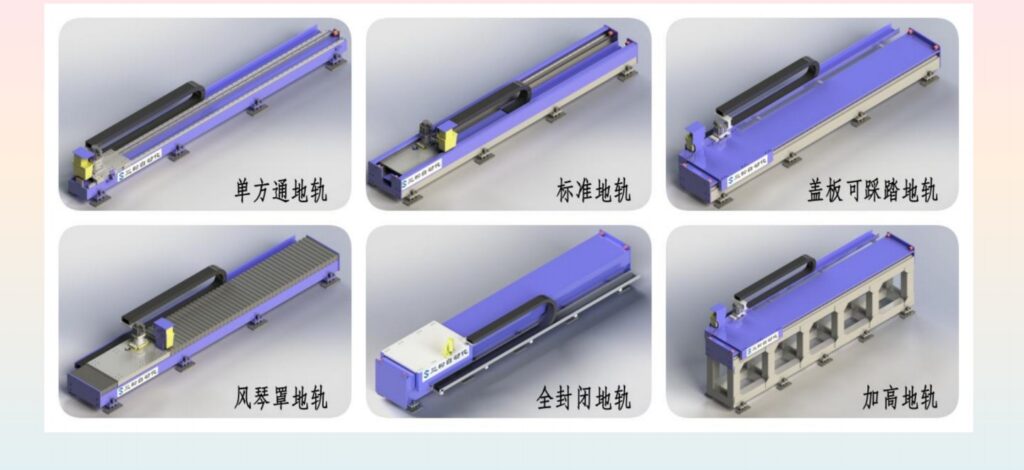

One advantage manufacturers value is customization. Track length, payload capacity, and travel speed can all be adjusted to fit different vehicle platforms and factory layouts, making these systems suitable for both new lines and retrofits.

What Manufacturers Gain from Linear Tracks

From a production standpoint, the benefits are very tangible. Throughput increases without sacrificing quality. Welds remain consistent shift after shift. And when new models are introduced, the line doesn’t need a complete redesign.

Over time, many manufacturers also see lower operating costs. Fewer robots, simpler layouts, and reduced maintenance translate into a healthier return on investment. That’s why linear tracks have become a standard feature in many modern body-in-white and chassis welding lines.

Looking Ahead: The Future of Chassis Welding

As the automotive industry continues to evolve—driven by electrification, lightweight materials, and smart manufacturing—the role of robotic linear tracks will only expand. When paired with offline programming, digital simulation, and intelligent monitoring, these systems offer a clear path toward scalable, future-ready welding solutions.

In short, linear tracks are no longer just an add-on. For many automotive manufacturers, they have become a key tool for staying competitive in a rapidly changing market.

Interested in upgrading your chassis welding line with robotic linear tracks?

Contact us to explore customized automation solutions tailored to your automotive production needs.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System