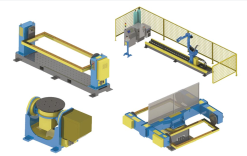

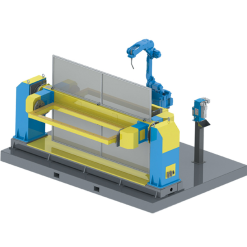

Description

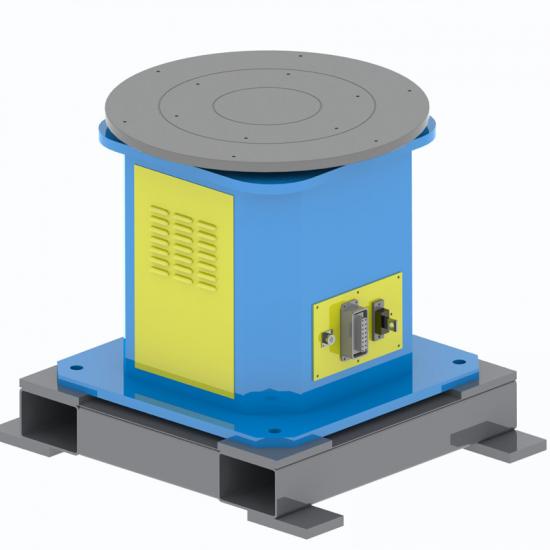

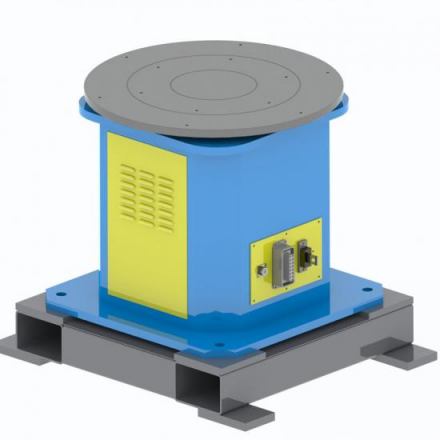

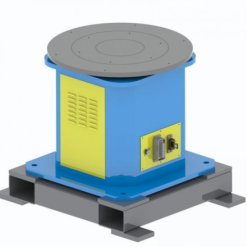

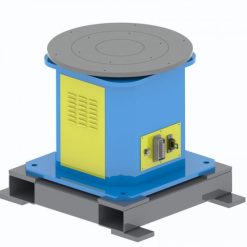

Horizontal Single Axis welding robot Servo positioner SWP-P-300

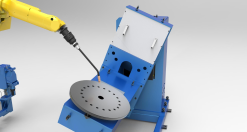

A welding robot positioner is a device that is used in conjunction with a welding robot to position the workpiece at a desired angle and orientation during the welding process.

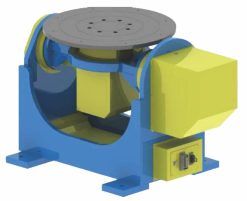

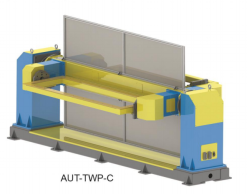

This horizontal single-axis servo positioner consists of a fixing base, rotary main spindle case, horizontal rotary disk, AC servo motor, RV precise reducer, conductive system, protective cover, and electrical control system.

The fixed base is welded with high-quality profiles, after annealing stress and special mechanical treatment so the machining accuracy and the use accuracy are assured. Antirust appearance paint is beautiful and elegant, and the color can be customized.

rotary main spindle case is made with high-quality profiles, after annealing and special mechanical treatment to ensure durability and stability after a long time of use.

The horizontal rotary disc is made with high-quality quality profiles, after annealing stress and special mechanical treatment so the degree of surface finish and the stability are assured. With a standard pitch-tapped hole on the surface, it’s easy to install positioning tooling.

The AC servo motor matching the RV reducer can guarantee high rotary stability, high positioning accuracy, long durability, and a low failure rate.

We choose brass as the conductive material because it has good electrical conductivity. The conducting substrate is integral isolated, so the servo motor, robot body, and welding power source are completely safe.

We choose Omron(Japan) PLC to control the positioner, electrical elements are all from famous brands so it has stability and a low failure rate.

Advantages

- Precise Positioning and accommodating various robot models and sizes, making it adaptable to different industrial applications.

- Smooth and Stable Movement and Enhanced Safety Features.

- High Payload Capacity, Increased Productivity, and Efficiency.

- Cost-Effective Solution: Investing in a robot positioner and linear track system offers a cost-effective solution for automating industrial processes. By streamlining operations, reducing errors, and improving overall efficiency, the system helps lower production costs, increase output, and improve the return on investment (ROI) in the long run

Specs

| No | Item | SWP-P-300 | SWP-P-500 |

| 1 | Rated load | 300kg(within main axis radius R500mm) | 500kg (within main axis radius R500mm) |

| 2 | Standard radius of rotary | R600mm | R600mm |

| 3 | Maximum angle of rotary | ±360° | ±360° |

| 4 | Rated speed of rotary | 70°/S | 70°/S |

| 5 | Repeated positioning accuracy | ≤1.0arcmin | ≤1.0arcmin |

| 6 | Dimension(L×W×H) | 800mm×600mm×755mm | 800mm×600mm×795mm |

| 7 | Height of adapter plate | 750mm | 790mm |

| 8 | Standard adapter plate | Φ360mm | Φ400mm |

| 9 | Power supply | Three phase 200V ±10% 50Hz (with isolation transformer) | Three phase 200V ±10% 50Hz (with isolation transformer) |

| 10 | Insulation grade | H | H |

| 11 | Body weight | about 260kg | about 350kg |

Application

Packing details

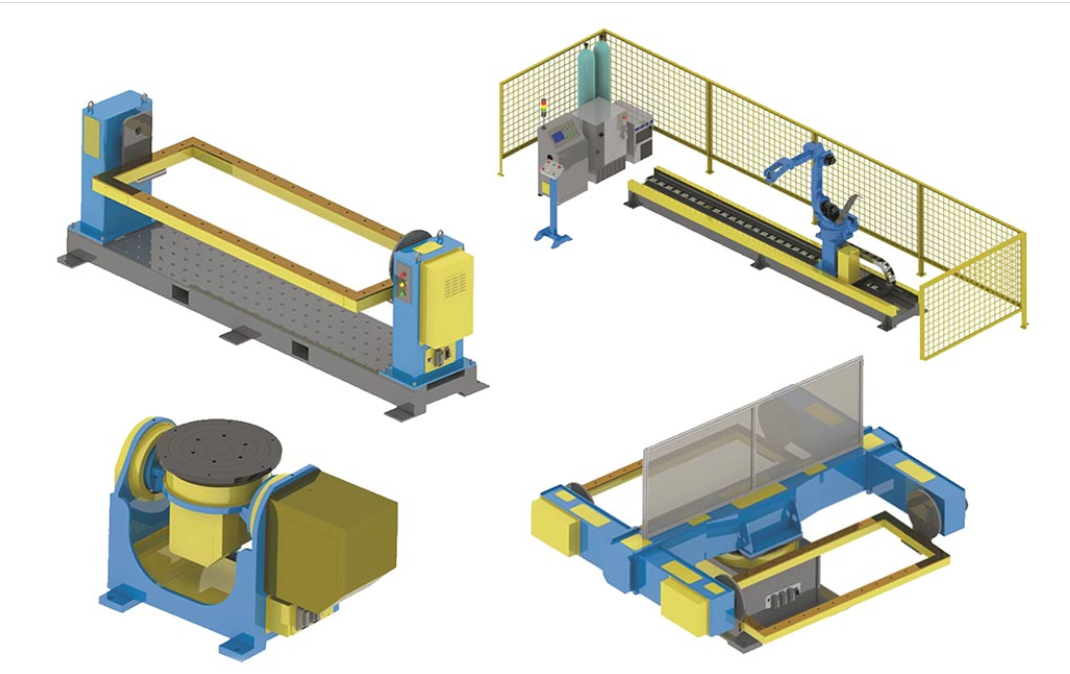

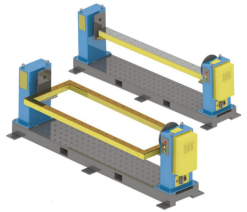

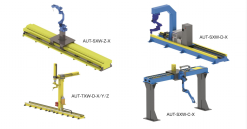

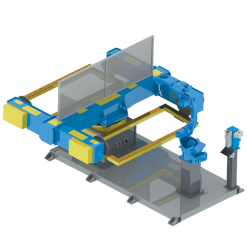

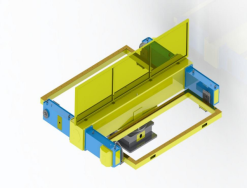

Robot Linear track

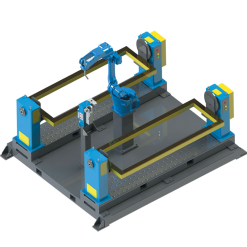

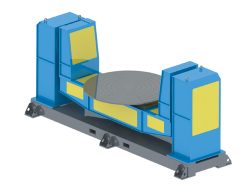

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Factory delivery robot

Factory delivery robot Welding Robot

Welding Robot Robot Gantry System

Robot Gantry System