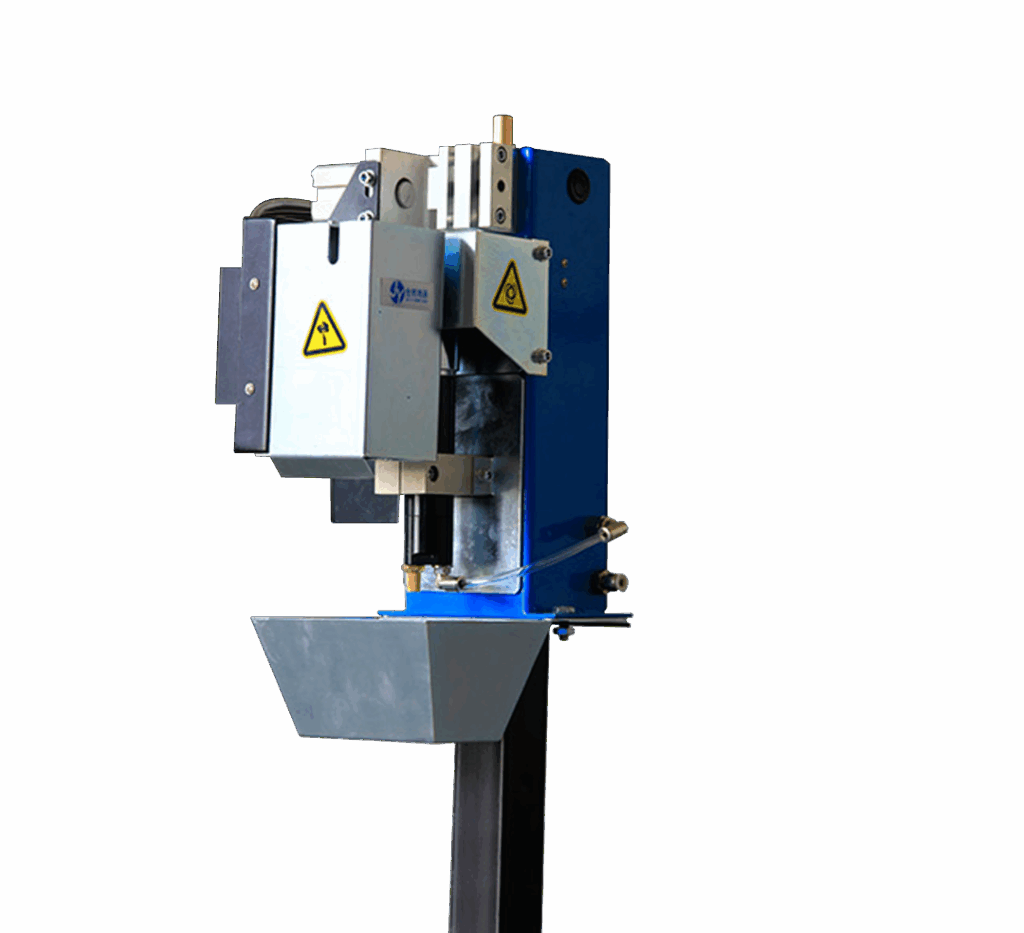

JY-2000S Robotic Torch Cleaning Station – Key Features and Engineering Advantages

In automated welding production, torch condition directly affects arc stability, bead appearance, and overall weld quality. The JY-2000S robotic torch cleaning station is designed to address this reality with a practical, integrated approach, combining multiple maintenance functions into a single, reliable unit.

Integrated “Three-in-One” Design for Real Production Environments

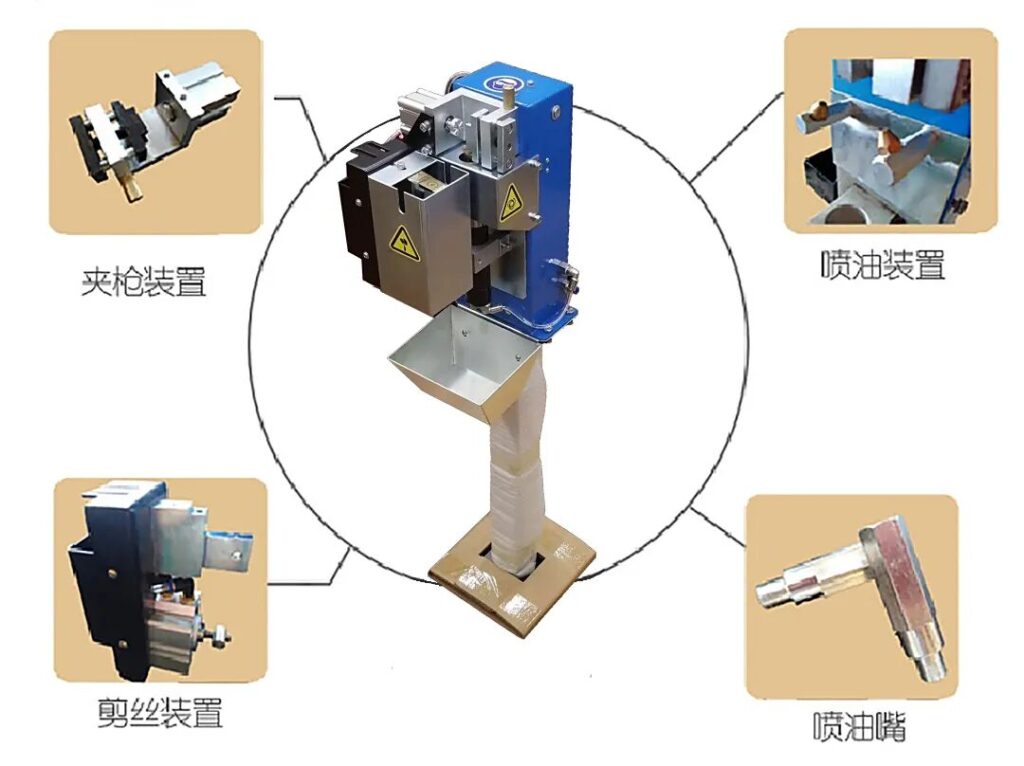

The JY-2000S offers a clear advantage through its three-in-one integration: torch cleaning, anti-spatter spraying, and wire cutting are all performed within one station.

In traditional welding setups, these tasks are often handled by separate devices or require multiple manual steps. This increases floor space usage and interrupts workflow. By consolidating these functions, the JY-2000S simplifies torch maintenance and significantly improves efficiency.

In an automotive welding workshop, for example, torch cleaning, spraying, and wire cutting were previously handled by separate units. Maintenance cycles were slow, and transitions between devices caused unnecessary downtime. After switching to the JY-2000S, all three operations could be completed sequentially in one stop. Torch maintenance time was reduced noticeably, and overall line efficiency improved.

This integrated design also lowers total ownership cost. Fewer machines mean lower procurement, simplified maintenance, and reduced spare parts inventory.

Pneumatic Program Control: Reliable, Fast, and Clean

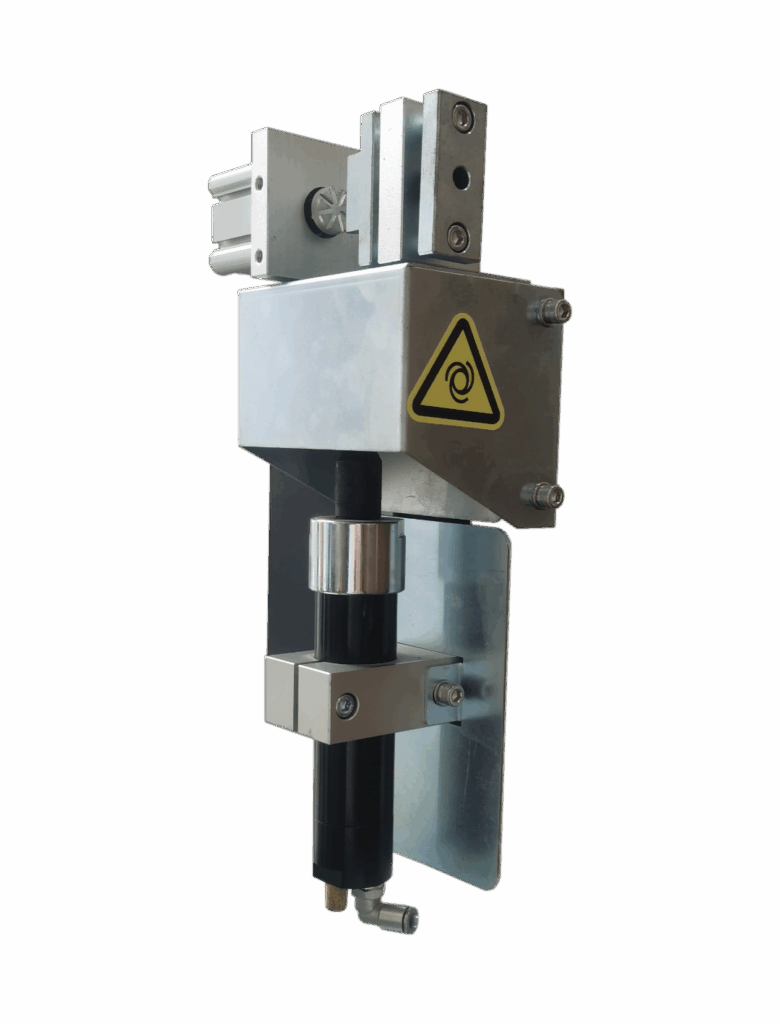

The JY-2000S uses pneumatic program control, a proven solution for demanding industrial environments.

From an engineering perspective, pneumatic systems offer high reliability due to their simple structure and limited number of moving parts. This makes them well suited for continuous operation in welding shops where stability matters more than complexity.

Response speed is another advantage. During robotic welding cycles, torch cleaning, spraying, and wire cutting must happen quickly and precisely. The pneumatic system reacts immediately to control signals, ensuring accurate and repeatable operation.

Equally important, pneumatic control is clean and environmentally friendly. Unlike hydraulic systems, there is no risk of oil leakage. This makes the JY-2000S especially suitable for industries with strict cleanliness standards, such as electronics manufacturing or high-spec fabrication workshops.

Practical Anti-Spatter Agent Capacity Design (500 ml)

The JY-2000S is equipped with a 500 ml anti-spatter agent reservoir, a capacity chosen based on real production needs rather than theoretical maximums.

Anti-spatter fluid plays a critical role in preventing weld spatter from adhering to the nozzle and contact tip. If the reservoir is too small, frequent refilling increases operator workload and risks interruptions. If it is too large, equipment size and cost increase, and long-term storage can affect fluid quality.

In practice, 500 ml provides a good balance. For a medium-duty structural steel fabrication shop, this capacity supports extended welding operations without frequent refilling, while avoiding unnecessary waste. The refill process itself is simple and quick, ensuring minimal disruption to production.

High-Efficiency Torch Cleaning Performance

During welding, spatter and debris gradually accumulate on the nozzle and contact tip, affecting arc stability and weld consistency. The JY-2000S addresses this with an efficient mechanical cleaning system, using high-speed rotating brushes or specialized cleaning tools to remove buildup thoroughly.

In a machinery manufacturing workshop, torches that had accumulated heavy spatter caused unstable arcs and visible weld defects. After using the JY-2000S for routine cleaning, nozzles and contact tips returned to a clean condition, arc stability improved, and weld quality became more consistent.

The cleaning cycle is fast, reducing torch downtime and keeping robotic welding cells running efficiently.

Precise and Uniform Anti-Spatter Spraying

After cleaning, controlled anti-spatter application is essential. The JY-2000S delivers precise and uniform spraying, with adjustable volume and accurate positioning based on torch type and application requirements.

In precision welding applications, excessive spraying can contaminate welds, while insufficient coverage reduces protection. The JY-2000S balances this through a controlled spray system that applies just the right amount of anti-spatter agent to critical areas.

Uniform coverage ensures effective spatter prevention while minimizing fluid consumption and maintaining weld integrity.

Stable and Accurate Wire Cutting Function

Wire length consistency is another key factor in automated welding. The JY-2000S features a stable and precise wire cutting mechanism, designed with high-quality cutting blades and a reliable drive system.

In shipbuilding and heavy fabrication workshops, where wire length tolerance is tight, this function ensures consistent stick-out length and stable welding conditions. The cutting action is accurate, repeatable, and durable, reducing maintenance frequency.

Noise levels during cutting are also kept low, improving the overall shop-floor working environment.

Conclusion

With its integrated three-in-one design, pneumatic program control, well-balanced anti-spatter capacity, and reliable cleaning, spraying, and wire cutting functions, the JY-2000S robotic torch cleaning station delivers practical value in automated welding applications.

From automotive and machinery manufacturing to electronics, shipbuilding, and structural steel fabrication, the JY-2000S helps manufacturers:

-

Improve welding quality

-

Reduce downtime

-

Lower operating costs

-

Maintain stable robotic welding performance

As welding automation continues to advance, reliable peripheral equipment like the JY-2000S plays an increasingly important role in keeping production lines efficient and consistent.

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System