Introduction

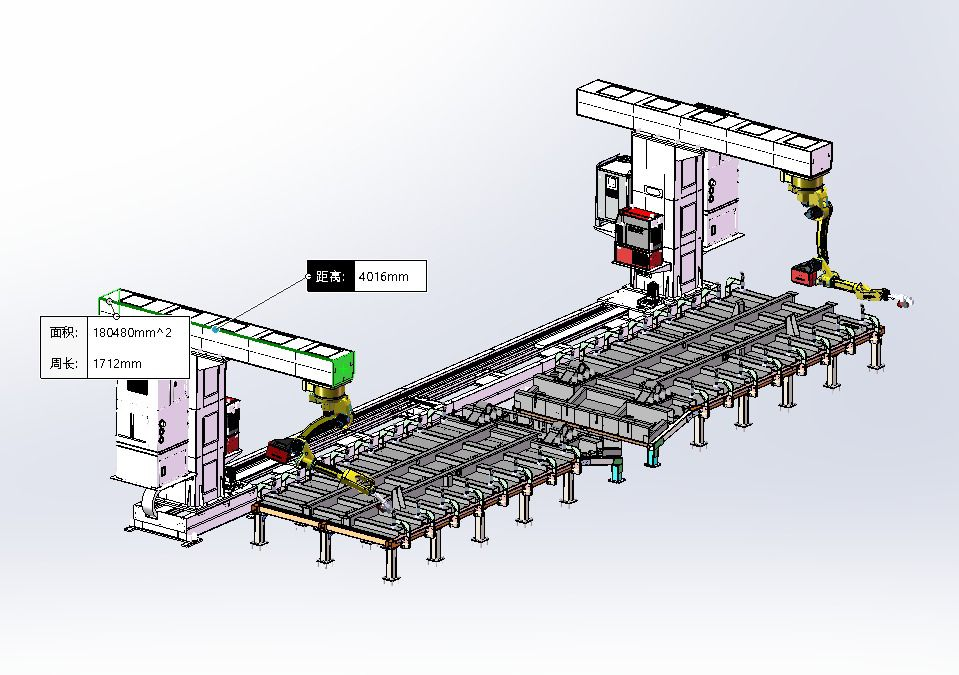

In the high-stakes environment of automotive assembly, throughput is the ultimate metric of success. However, as vehicle chassis grow in complexity and size, traditional fixed robotic cells often hit a “reach wall.” These static setups force complex workpiece maneuvering and increase non-productive cycle time. To address this, leading Tier-1 manufacturers are integrating advanced linear motion into their welding cells. By utilizing a Robot track , the production line transforms from a series of isolated points into a continuous, fluid process. This strategic deployment of linear tracks allows for sub-millimeter precision across the entire 3D work envelope of the chassis.

The Evolution from Static to Dynamic Work Envelopes

A standard 6-axis robot operates within a spherical reach. When welding a 5-meter truck chassis, this sphere is simply too small.

- Extended Kinematic Reach:Linear tracks effectively turn the robot’s reach from a fixed ball into a massive, elongated capsule, extending up to 30 meters if necessary.

- High-Inertia Stability:Chassis welding requires heavy, high-torque end-effectors. The AUT-DW series is engineered to maintain structural rigidity under cantilever loads of up to 500kg.

- Synchronization Accuracy:Through the use of precision planetary reducers and gear-rack drives, the system ensures a repetitive positioning accuracy of $\leq 0.1$mm.

Deep Technical Analysis: Synergy of Kinematic Expansion and Multi-Axis Synchronization

In modern chassis lines, the Linear Track is no longer just a “mover”; it is a fully integrated “7th Axis.” This integration redefines how the robot interacts with the workpiece.

1. Decoupling Geometry from Production Tact

In a fixed setup, the chassis must be indexed or rotated to meet the robot. This adds “air time” where no welding occurs. By moving the robot base instead, you decouple the physical dimensions of the chassis from the mechanical limits of the arm. This allows the robot to maintain an Optimal Welding Pose—the specific orientation where the arm has maximum rigidity—across the entire frame.

2. Managing Singularities and Joint Torque

When a stationary robot reaches for a distant weld point, it often approaches Kinematic Singularities. In these zones, the robot loses degrees of freedom, and positioning accuracy fluctuates. By using a linear track to keep the robot base close to the weld target, the arm stays within its “sweet spot.” This optimizes joint velocity and significantly extends the service life of the J1 and J2 reducers.

3. Computational Efficiency in Unified Coordinates

Integrating the track as a coordinated axis simplifies the Inverse Kinematics calculations. Instead of complex hand-offs between multiple fixed points, the system operates within a single, continuous frame of reference. This synchronization is vital for the deep-penetration welds required in heavy-duty commercial vehicle frames.

Optimizing Factory Logistics and TCO

Beyond the weld seam, linear tracks reshape the economics of the factory floor.

- The Overhead Highway:Implementing a bridge-style gantry track reclaims valuable floor space. It allows Autonomous Mobile Robots (AMRs) to pass freely beneath the active workspace.

- Simplified Maintenance:Linear tracks use transparent mechanical principles—racks, pinions, and guides. These are significantly easier for in-house teams to maintain than the sealed internal gearboxes of an articulated arm.

- Modular Scalability:Since our tracks use 4-meter combinable sections, the line can grow as your production targets increase, reducing the risk of stranded capital.

Conclusion

Streamlining chassis welding is no longer just about faster robots; it is about smarter motion. By integrating Linear Tracks, automotive manufacturers achieve the stability, reach, and precision required for the next generation of vehicle platforms. Ultimately, this multi-axis synchronization provides the operational agility needed to lead in a rapidly changing market.

Get a Custom Technical Proposal tailored to your facility’s layout and payload requirements, and see how we can expand your production’s dynamic reach.

Robot Linear track

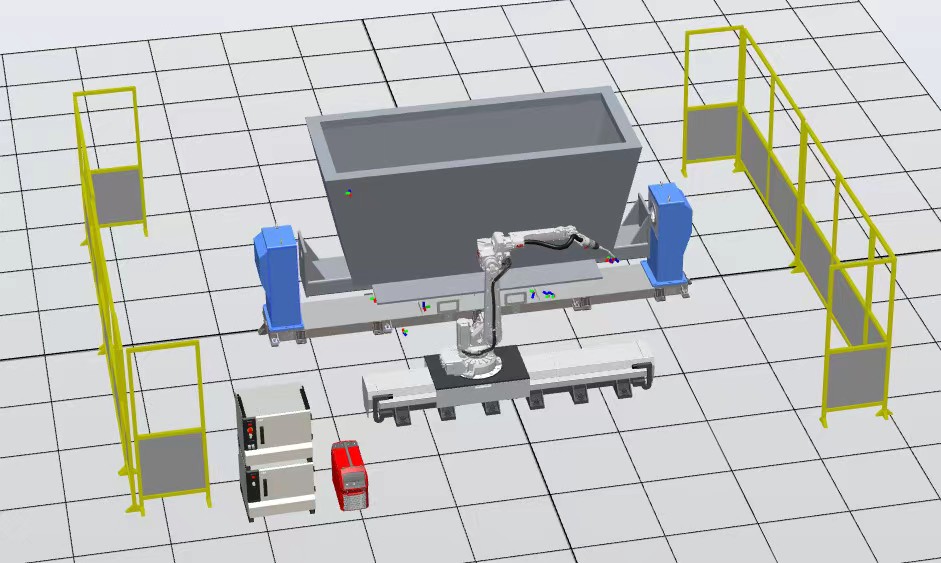

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Welding Robot Workstations & Automation Solutions

Welding Robot Workstations & Automation Solutions Robot Gantry System

Robot Gantry System