1. Comprehensive Product Overview

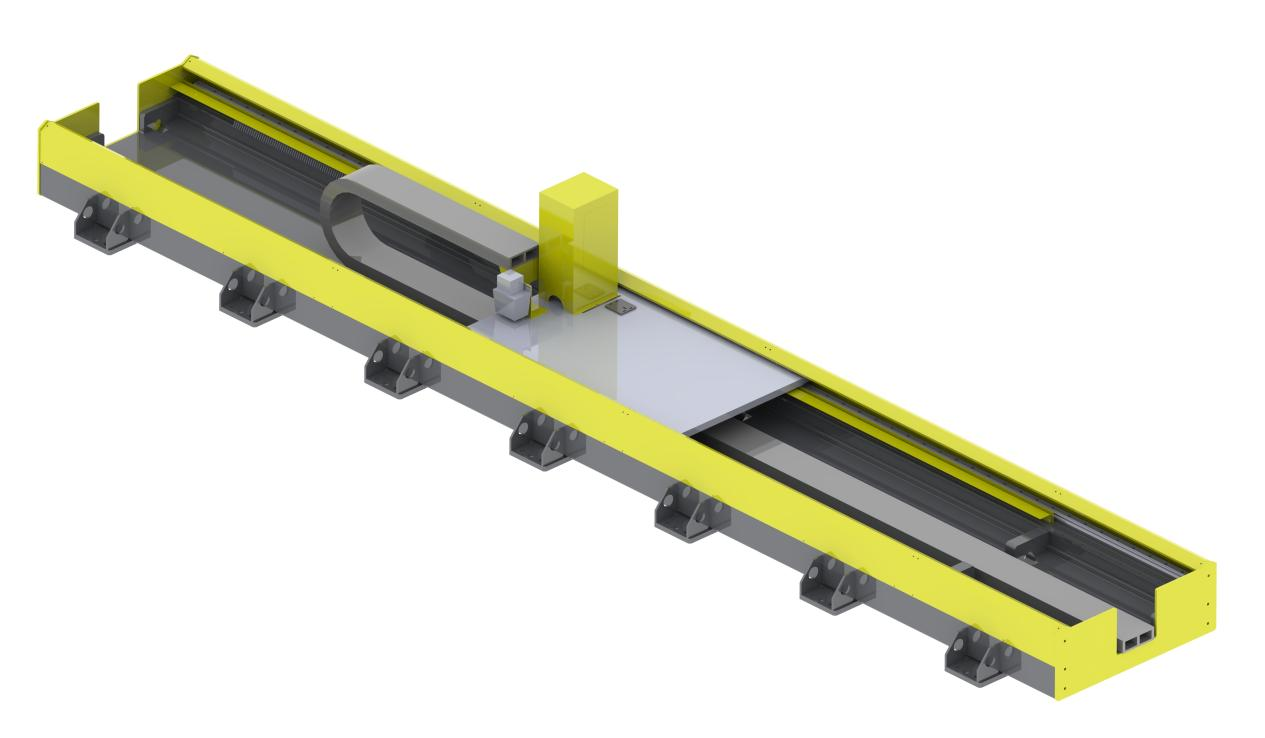

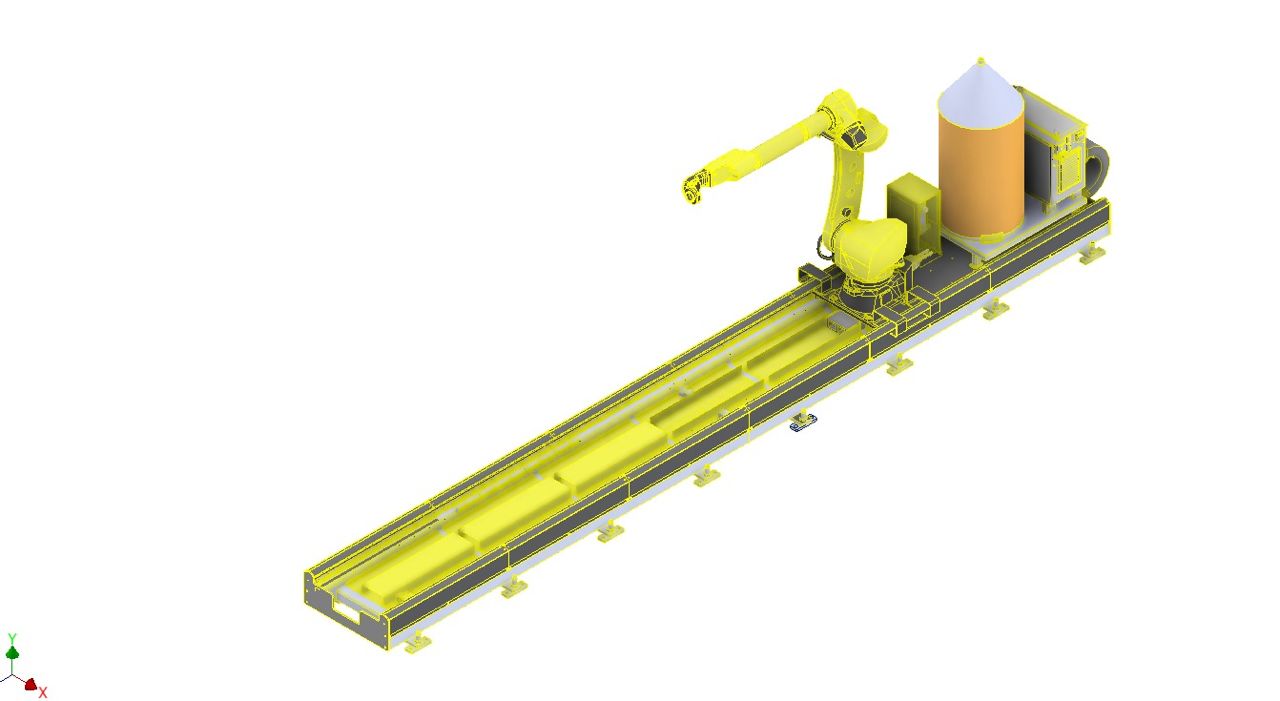

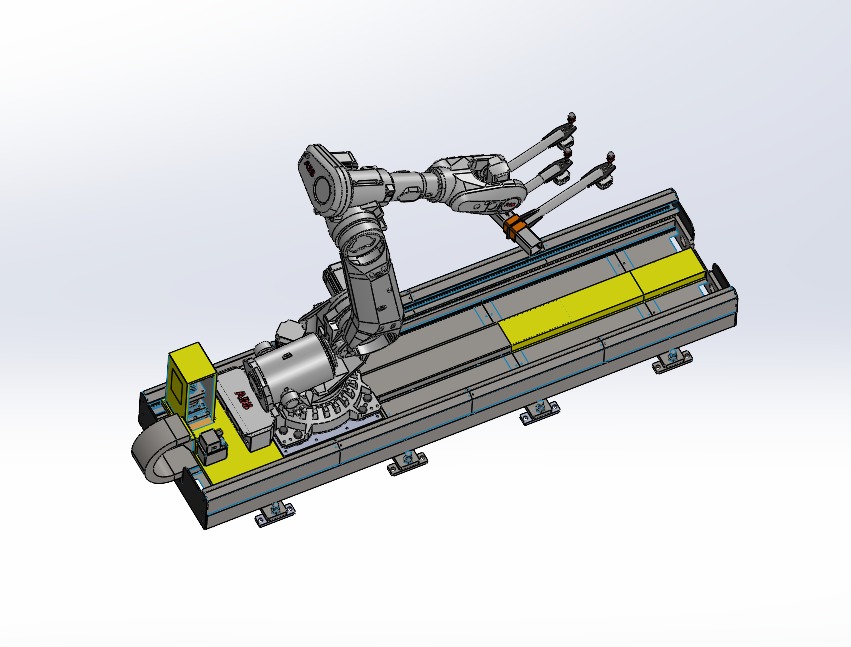

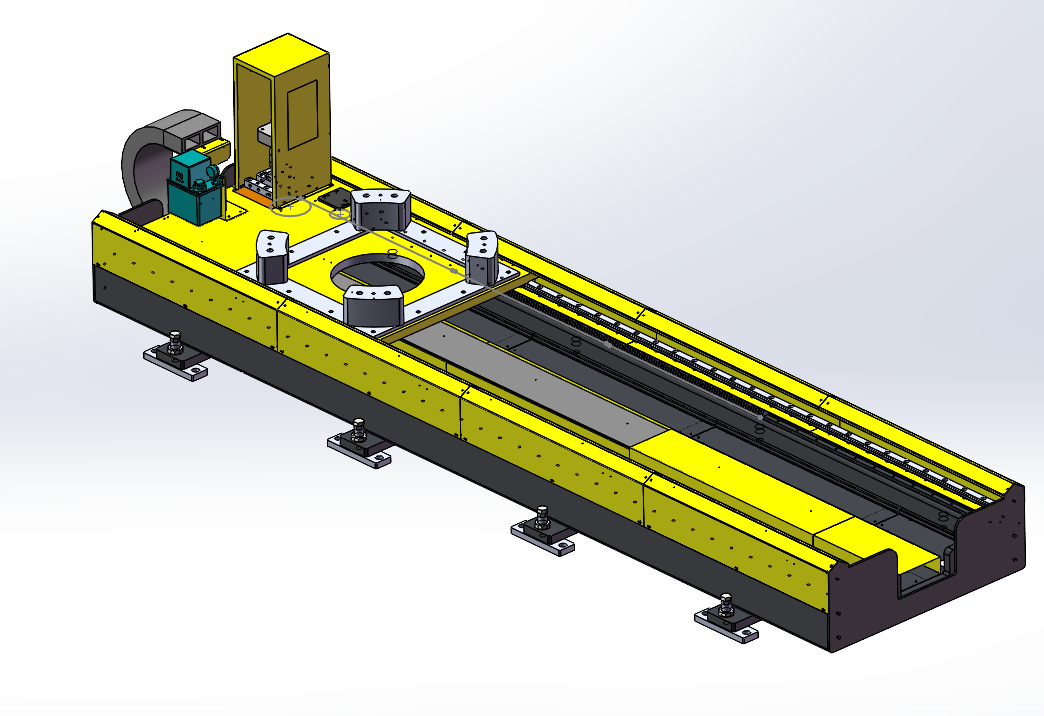

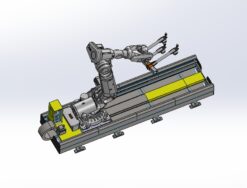

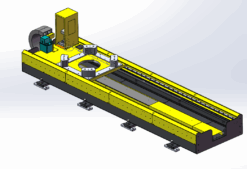

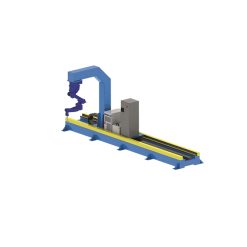

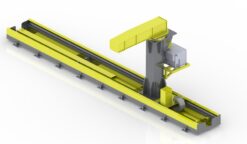

The Medium-Duty Robot Travel Rail serves as a specialized linear motion foundation, purpose-built to meet the rigorous demands of the modern welding automation industry. In many traditional setups, the efficiency of an industrial robot is limited by its static mounting position. This high-precision travel rail acts as a “Seventh Axis,” effectively breaking those spatial boundaries by enabling the robot to traverse smoothly along the X-axis.

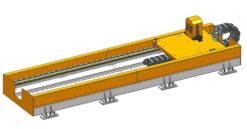

By integrating this travel system, manufacturers can significantly enhance the operational envelope of their welding robots. It allows a single robot to transition between multiple working stations or process exceptionally long workpieces—such as chassis frames or structural beams—in a single continuous pass. The system is engineered around a high-performance servo motor and a precision rack-and-pinion transmission, ensuring that every movement is synchronized and vibration-free.

2. Technical Specifications

To provide a clear understanding of the system’s capabilities, the following table outlines the engineering standards and physical limits of the AUT-DW Series travel rail:

| Item | Specification |

| Product Type | Single-Axis Servo Robot Travel Rail |

| Control Axis | X-axis |

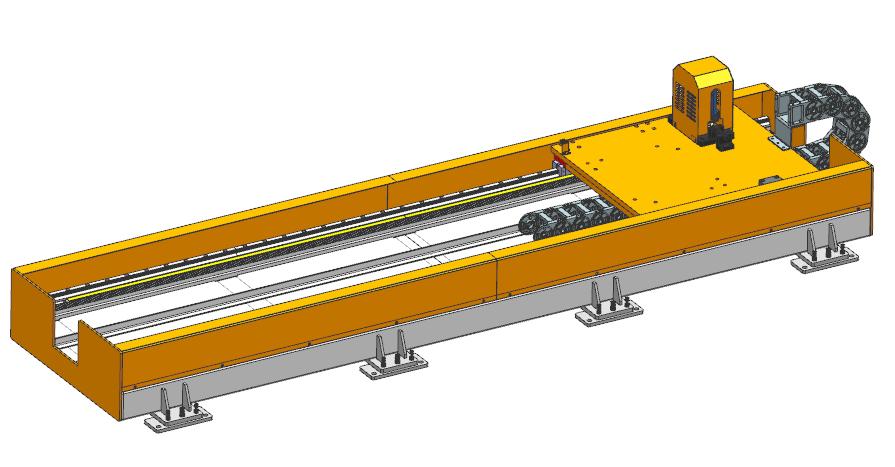

| Drive System | AC Servo Motor with Planetary Gearbox |

| Gearbox Ratio | i = 20 |

| Transmission Type | Helical Gear Rack Drive |

| Guiding System | Linear Guide Rails with Sliding Blocks |

| Installation Type | Ground-Mounted Installation |

| Maximum Travel Speed | ≤ 40,000 mm/min |

| Repeatability Accuracy | ±0.10 mm |

| Effective Stroke | Rail Length minus 1,400 mm |

| Maximum Total Load | ≤ 3,000 kg |

| Maximum Robot Payload | ≤ 300 kg |

| Lubrication System | Automatic Lubrication |

| Protective Structure | Semi-Enclosed Sheet Metal Cover |

| Surface Treatment | Powder-Coated Finish |

| Typical Applications | Welding and Material Handling Automation |

3. Key Technical Features and Performance Standards

When it comes to robotic welding, precision is the difference between a perfect seam and a costly rework. This system is designed with a set of core features that prioritize accuracy and uptime:

- Sub-Millimeter Repeatability:With a repeat positioning accuracy of up to ±0.10 mm (on the Y-axis), our rail delivers the consistency needed for high-quality weld beads even over long travel distances.

- Helical Gear Transmission:Unlike standard straight-cut gears, we utilize a precision rack and pinion system with helical gears. This design increases the contact ratio, providing smoother power transmission and higher torque capacity during high-speed transitions.

- Intelligent Maintenance:To minimize manual intervention, the system features an integrated automatic lubrication module. It periodically delivers the exact amount of 46# guide rail oil required, preventing dry friction and extending mechanical life.

- Modular Scalability:The rail utilizes a modular sectional design (4 meters per section). This allows for a flexible configuration up to 30 meters, meaning the system can be custom-fitted to your floor space and easily extended in the future.

4. Structural Design, Rigidity, and Reliability

The foundation of any high-precision linear axis is its structural stability. Our medium-duty travel rail is manufactured using high-quality steel profiles and heavy-duty plates.

Advanced Heat Treatment: All structural steel components undergo professional stress-relief heat treatment. This eliminates the internal stresses created during welding, ensuring that the rail stays perfectly straight over years of multi-shift operation.

Environmental Shielding: Welding is characterized by high heat and flying spatter. Our rail is protected by robust, powder-coated sheet-metal covers that form a semi-enclosed barrier. This prevents weld spatter from adhering to the precision gear teeth, which is a leading cause of premature failure in unprotected systems.

5. Typical Industrial Applications

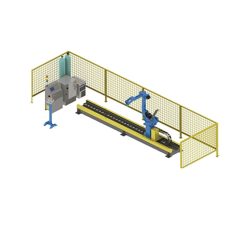

This travel rail is a versatile asset across several demanding heavy-industry sectors:

- Automated Welding Production Lines:Widely used in multi-station cells where one robot serves several welding jigs in sequence.

- Steel Structure & Infrastructure:Essential for the fabrication of bridge trusses and large-scale architectural frames.

- Construction Machinery:The go-to solution for welding long-reach excavator arms, crane booms, and heavy-duty chassis components.

- Shipbuilding:Managing hull sections and deck structure welding with its extended 30m reach.

6. Why Invest in This Travel Rail Solution?

Selecting the right travel rail is about more than just moving a robot; it’s about ensuring the stability of your entire automation process. This system is optimized specifically for welding automation equipment, designed with an understanding of the thermal and physical stresses of the factory floor.

By choosing this modular solution, you are investing in a flexible, low-maintenance foundation that allows your production line to scale. It integrates seamlessly with major robot controllers such as the Yaskawa YRC1000 and FANUC R-30iB, ensuring a straightforward commissioning process.

7. Conclusion

The Medium-Duty Robot Travel Rail with High Precision is an efficient answer to the challenges of modern industrial automation. It combines heavy-duty strength with the sub-millimeter precision required for high-tech welding applications.

For custom engineering requests or to view our full integration catalog, we invite you to connect with our technical specialists.

Ask for quote

Robot Linear track

Robot Linear track Robot welding Positioner

Robot welding Positioner Robot Torch cleaning station

Robot Torch cleaning station Factory delivery robot

Factory delivery robot Welding Robot

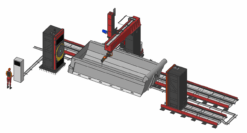

Welding Robot Robot Gantry System

Robot Gantry System